A drag reduction device and method for injecting foam into heavy oil in spiral slots

A drag reduction device and spiral groove technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as increased process, large energy consumption, pipeline corrosion, etc., to facilitate replacement and maintenance, and avoid direct contact. , the effect of increasing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

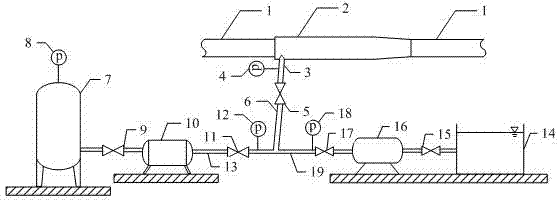

[0027] First, combine the flow characteristics of the heavy oil and the actual working conditions on site to determine the specific pipe section that needs to be installed with the device of the present invention. The device is composed of a skid, and only the bubble injector 2 needs to be installed in the form of a short connection on the heavy oil pipeline 1. , It can be fixed with the upstream and downstream pipelines through threaded connection.

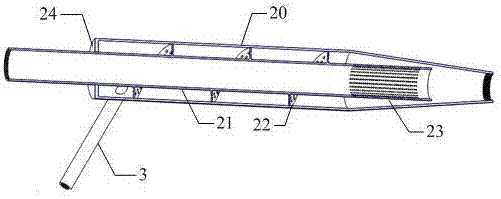

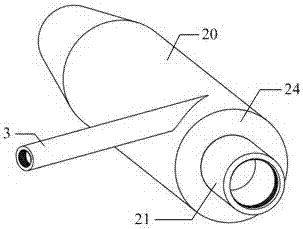

[0028]The gas injection unit and the water injection unit respectively provide the mixed gas source and water source for the bubble injector 2. The mixing flow and pressure of gas and water are determined by the water pump 16, the frequency of the gas compressor 10, the water injection valve 17, the gas injection valve 11, and the inlet valve. 5 adjustments. Gas and water are initially mixed in the gas-liquid mixing pipe 6, and then enter the annular space of the bubble injector 2 through the tangential injection pipe 3. Under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com