Piezoresistive/piezoelectric interlayer material and preparation and application methods thereof, and interlayer type sensor and preparation and application methods thereof

A sandwich material, piezoelectric sensing technology, applied in chemical instruments and methods, the use of electric/magnetic devices to transmit sensing components, lamination and other directions, can solve the problems of insufficient toughness, deformation and dislocation of the package shell and the internal core sensor components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

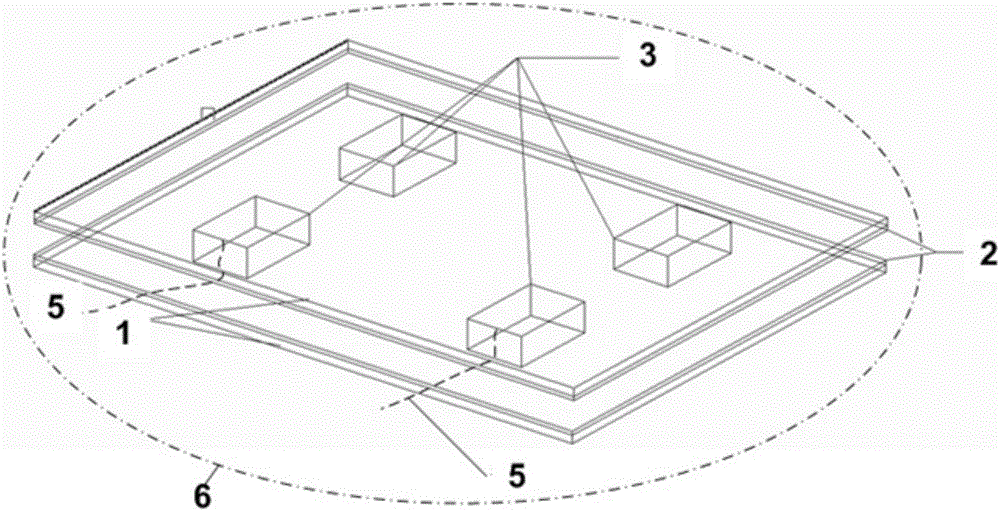

[0043] Such as figure 1 As shown, the sandwich sensor using piezoresistive / piezoelectric interlayer materials of the present invention includes a tough substrate 1, a self-assembled film piezoresistive sensing functional layer 2 (including top / bottom electrodes), a piezoelectric sensing elastic sandwich functional layer 3. The encapsulation layer 5 and the electromagnetic shielding wire 6 connected to the top / bottom electrodes and penetrating the encapsulation layer. The electromagnetic shielding wire 6 is connected to the electrode static / dynamic signal acquisition system through the shielding connector.

[0044] The preparation steps of the piezoresistive / piezoelectric interlayer material are as follows:

[0045] (1) Preparation of CNT self-assembled film piezoresistive sensing functional layer (top / bottom electrode layer)

[0046] ①Introduction of negatively charged functional groups on the surface of CNT

[0047] Pretreatment and purification of CNT: Weigh a certain am...

Embodiment 2

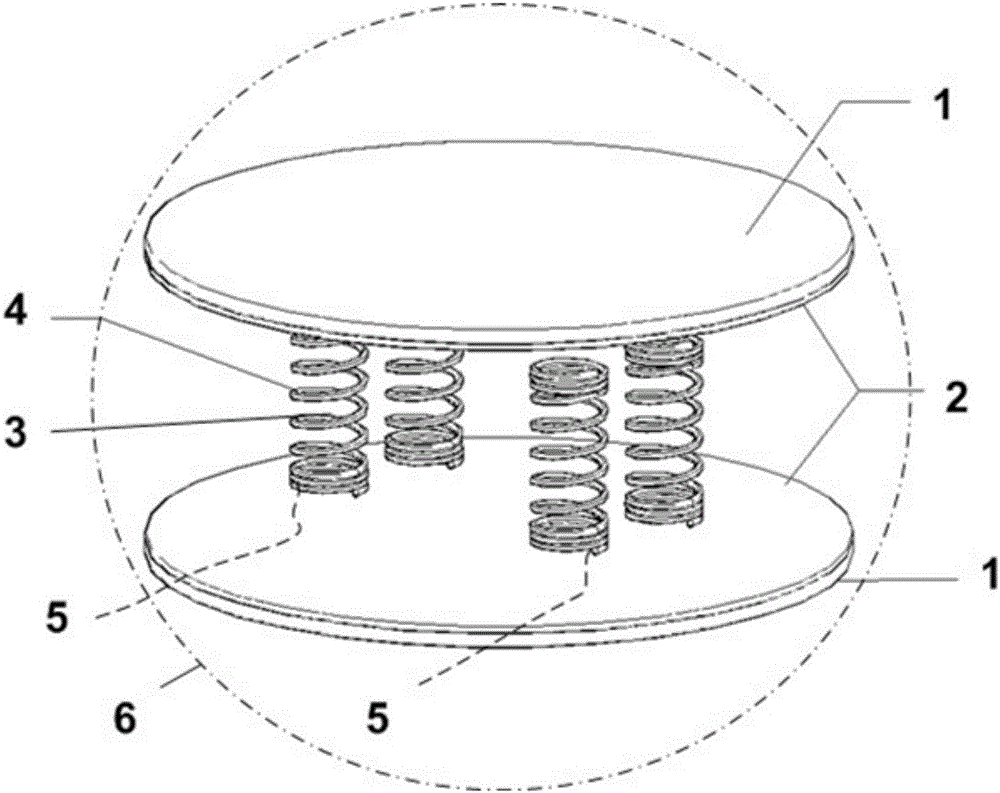

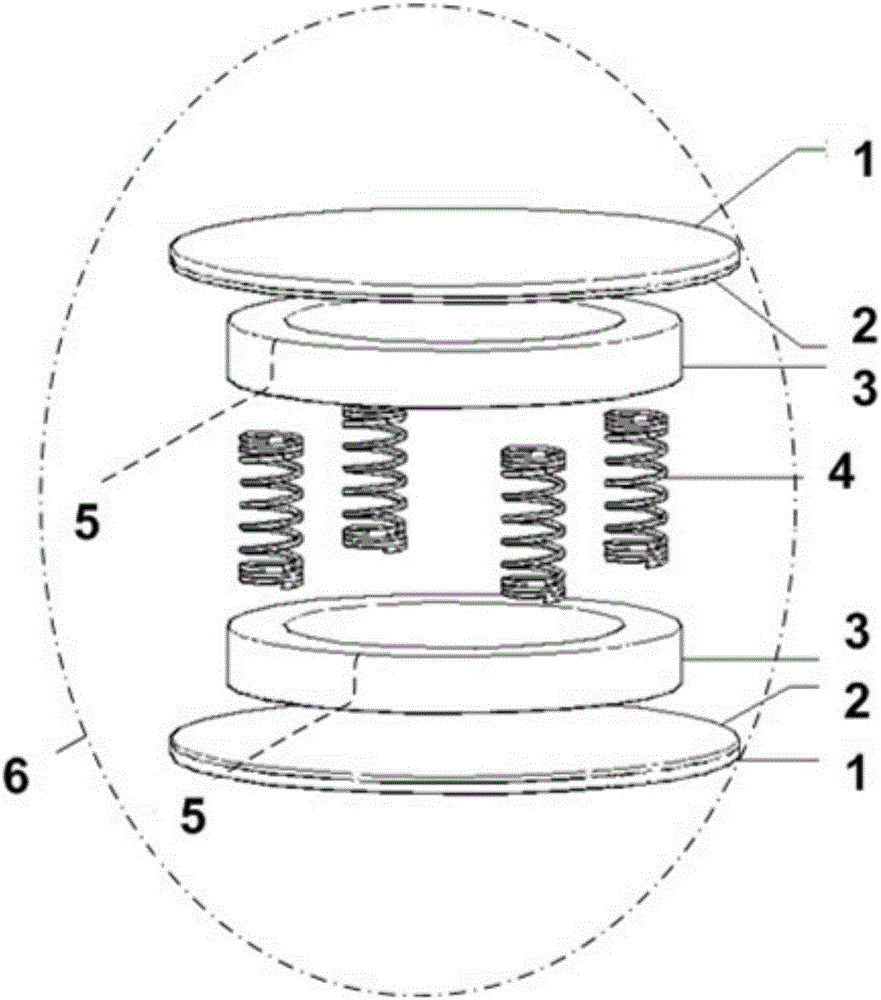

[0070] Such as figure 2As shown, the tough substrate is disc-shaped, and the piezoelectric sensing elastic core functional layer 3 is attached to the outer surface of the spring 4 . Wherein the piezoelectric sensing elastic core functional layer of the CNT / ZnO sensor is the CNT self-assembled thin film piezoresistive film prepared by spinning the ZnO / PDMS slurry prepared in step (2) in Example 1. Sensing the inner layer of the top / bottom electrode of the functional layer and the surface of four stainless steel springs with equal length and stiffness; and while the ZnO / PDMS slurry is still in a semi-fluid state, the four corners of the interlayer stainless steel springs are symmetrically arranged on the top of the oppositely bonded CNTs. / Between the bottom electrode; finally transfer to a vacuum box, set the vacuum degree, temperature and reaction time to 0.05Pa, 40°C and 36 hours respectively, to obtain the CNT / ZnO piezoelectric sensing elastic sandwich functional layer.

...

Embodiment 3

[0075] The preparation process and structure of the piezoresistive / piezoelectric interlayer sensor are the same as in Example 1. The difference is: the nano conductive material used is GO (thickness 3-5 nanometer sheet, area average 2.7μm 2 , conductivity greater than 2S / cm); the piezoelectric sensing elastic core functional layer is a slurry made of polyvinylidene fluoride (PVDF) powder ultrasonically assisted in dissolving N-methylpyrrolidone, and then mixed with PDMS and PDMS curing agent made.

[0076] Using LCR digital bridge, quasi-static measuring instrument, and impedance analyzer to test the DC resistivity of 6 double-layer GO films in GO / PVDF piezoresistive / piezoelectric interlayer sensors, the DC resistivity is 398.4kΩ·cm, and the AC resistivity at 10kHz frequency 15.2kΩ cm; the piezoelectric gauge coefficient of the PVDF / PDMS layer is 21.5pC / N; combined with Wheatstone bridge technology and dynamic signal acquisition technology to study the sensitivity of the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com