Efficient preparation method for flexible ultra-extension conductive thin film based on one-dimensional nano material

A technology of nano-materials and conductive films, which is applied in the field of nano-optical materials, can solve the problems of film damage, low efficiency, and the inability to pre-stretch the film, and achieve the effects of complete transfer, simple preparation process, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

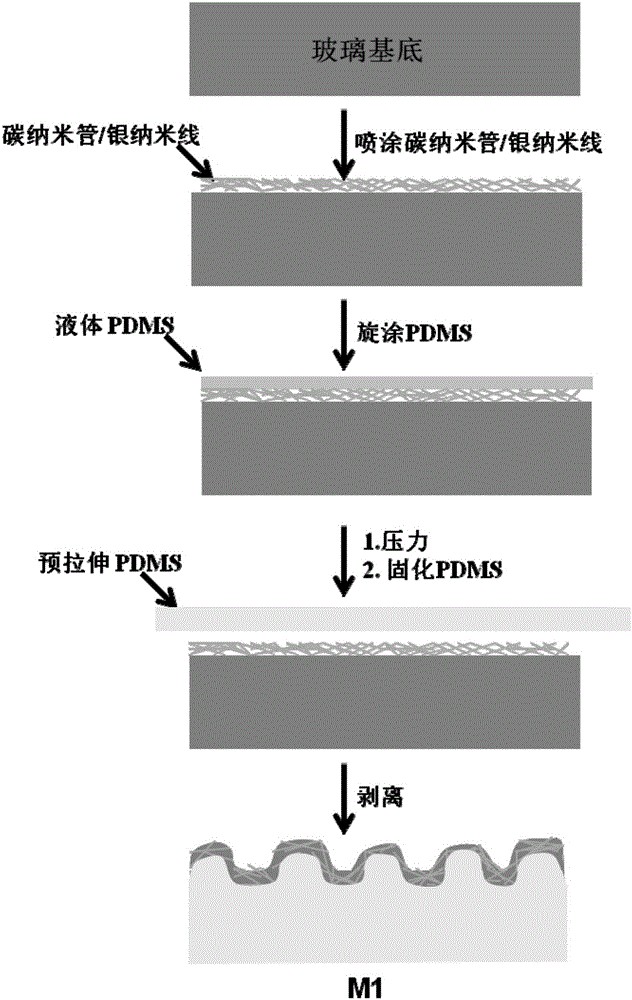

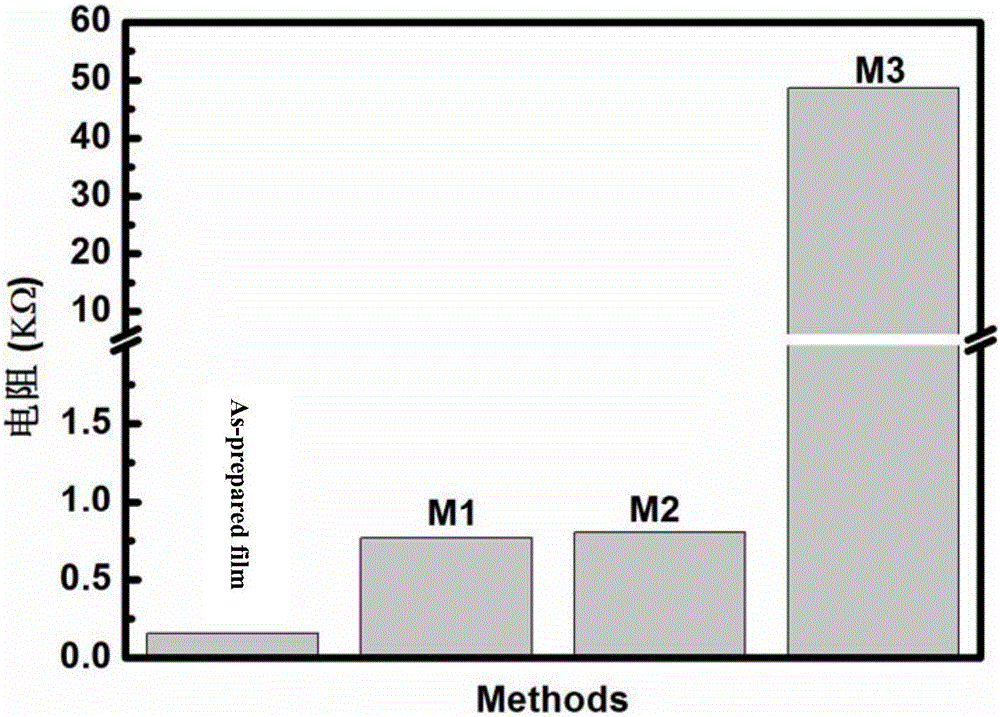

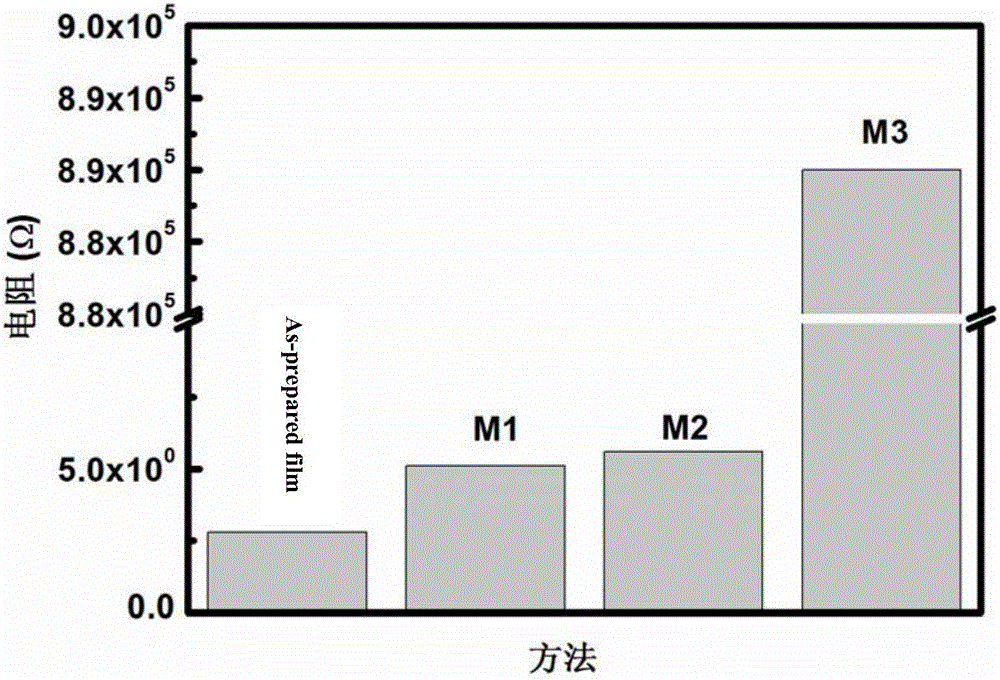

[0034] A high-efficiency preparation method based on carbon nanotube flexible super-extended conductive film, comprising the following steps:

[0035] a. Fabrication of flexible and stretchable PDMS substrates

[0036] 1) Mix basic component A and curing agent B at a mass ratio of 10:1, stir for 30 minutes, mix evenly, and pump air bubbles;

[0037] 2) Mix components A and B without air bubbles, stir again for 10 minutes, and pump out air bubbles;

[0038] 3) Transfer it to a plastic petri dish and pump air bubbles;

[0039] 4) Place the culture dish at 70°C and cure for 7 hours;

[0040] 5) Finally, peel off the PDMS and the plastic Petri dish.

[0041] b. Preparation of one-dimensional nanomaterial solution

[0042] Take 0.01g of carbon nanotubes into a 15ml centrifuge tube, suck 10ml of ethanol with a straw, seal it with plastic sealing tape, put it into an ultrasonic machine with a power of 240w for 6 hours, centrifuge, and let it stand overnight.

[0043] c. Cleaning...

Embodiment 2

[0052] A high-efficiency preparation method based on silver nanowire flexible super-extended conductive film, comprising the following steps:

[0053] a. Fabrication of flexible and stretchable PDMS substrates

[0054] 1) Mix basic component A and curing agent B at a mass ratio of 10:1, stir for 30 minutes, mix evenly, and pump air bubbles;

[0055]2) Mix components A and B without air bubbles, stir again for 10 minutes, and pump out air bubbles;

[0056] 3) Transfer it to a plastic petri dish and pump air bubbles;

[0057] 4) Place the culture dish at 70°C and cure for 7 hours;

[0058] 5) Finally, peel off the PDMS and the plastic Petri dish.

[0059] b. Cleaning of glass sheets

[0060] Sonicate the cut 2.5*2.5cm glass slides in deionized water, isopropanol, ethanol, and deionized water for 10 minutes, and finally dry them with nitrogen.

[0061] c. Efficient preparation of ultra-extensible, highly stable, one-dimensional nanomaterial thin films:

[0062] 1) Take 5mg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com