Fuse Structure

A technology of fuse structure and fuse link, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of circuit short circuit, small contact area, etc., and achieve the effect of reducing current density and strengthening electron migration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments described herein relate to e-fuse structures in semiconductor chips, but e-fuse structures may also be used in other embodiments.

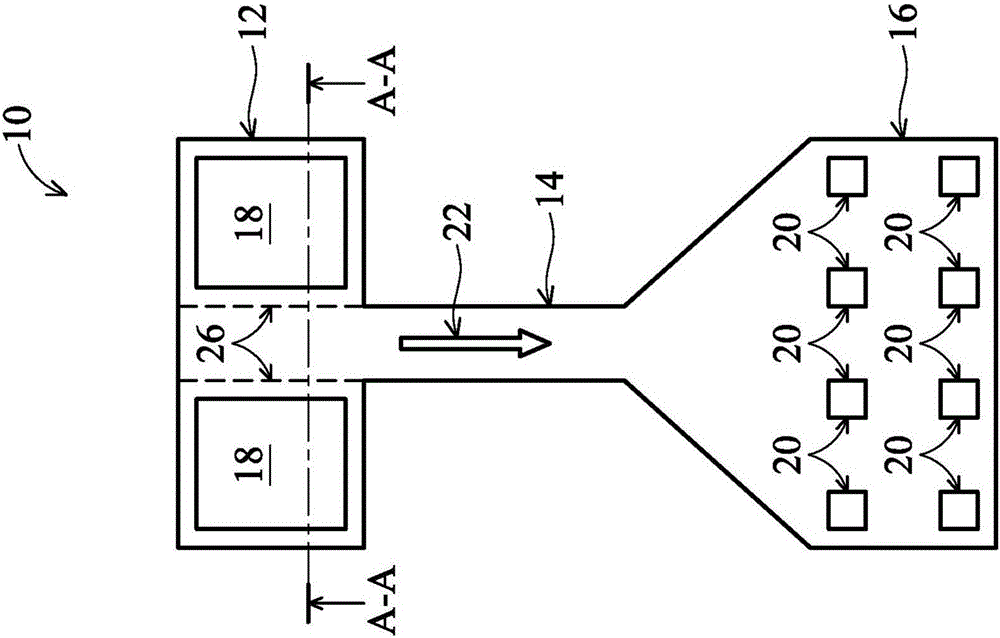

[0026] figure 1 A fuse structure 10 is shown including a cathode 12 , a fuse link 14 and an anode 16 . The fuse structure 10 can be made of metal, such as copper or similar metal materials, or made of polysilicon silicide (silicided polysilicon), such as nickel silicon (NiSi), titanium silicon (TiSi 2 ), cobalt silicon (CoSi x ), platinum silicon (PtSi 2 ) or similar material. The cathode 12 has a rectangular upper surface, and two contacts 18 are coupled to the upper surface. Anode 16 has a funnel-shaped upper surface, and contact window 20 is coupled to the upper surface. Contacts 18 and 20 may include copper, tungsten, or similar metals, and may also include a diffusion barrier layer including, for example, TiN, TaN, or similar material lined within contacts 18 and 20 . The width of fuse 14 (perpendicular to arrow 22 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com