Efficient processing technology for lead-acid rapidly-charged battery

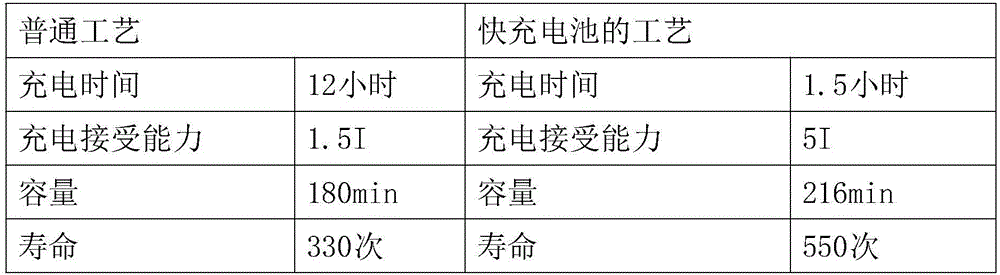

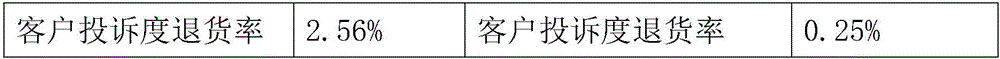

A processing technology and rechargeable battery technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve the problem of restricting the demand for continuous power supply, and achieve short charging time, extended life, and strong charging acceptance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high-efficiency processing technology for a lead-acid fast charging battery, the steps are as follows:

[0026] (1) Get 800kg of lead powder with a degree of oxidation of 72-80%, the fineness (particle size) of the lead powder≤120 mesh screen, and the passing rate is 99.7%;

[0027] (2) get the dilute sulfuric acid 90kg of material carbon 200kg, pure water 100kg and 1.40g / ml, prepare the material for later use;

[0028] (3) Add the above-mentioned lead powder and carbon material into the paste mixing machine and stir continuously for 8 minutes, then add 100kg of pure water and stir for 3 minutes, finally add dilute sulfuric acid and stir for 10 minutes, and set aside;

[0029] In the above step (3), the dilute sulfuric acid is added within 15 minutes; during the stirring process of the above step (3), the internal temperature of the paste mixer is controlled between 60°C.

[0030] (4) fill and coat the lead paste after stirring in step (3) on the pole plate, and spra...

Embodiment 2

[0034] A high-efficiency processing technology for a lead-acid fast charging battery, the steps are as follows:

[0035] (1) Get 800kg of lead powder with a degree of oxidation of 72-80%, the fineness (particle size) of the lead powder≤120 mesh screen, and the passing rate is 99.7%;

[0036] (2) get the dilute sulfuric acid 90kg of material carbon 200kg, pure water 100kg and 1.40g / ml, prepare the material for later use;

[0037] (3) Add the above-mentioned lead powder and carbon material into the paste mixing machine and stir continuously for 10 minutes, then add 100kg of pure water and stir for 3 minutes, finally add dilute sulfuric acid and stir for 10 minutes, and set aside;

[0038] In the above step (3), the dilute sulfuric acid was added within 18 minutes; during the stirring process of the above step (3), the internal temperature of the paste mixer was controlled between 62°C.

[0039] (4) fill and coat the lead paste after stirring in step (3) on the pole plate, and s...

Embodiment 3

[0043] A high-efficiency processing technology for a lead-acid fast charging battery, the steps are as follows:

[0044] (1) Get 800kg of lead powder with a degree of oxidation of 72-80%, the fineness (particle size) of the lead powder≤120 mesh screen, and the passing rate is 99.7%;

[0045] (2) get the dilute sulfuric acid 90kg of material carbon 200kg, pure water 100kg and 1.40g / ml, prepare the material for later use;

[0046] (3) Add the above-mentioned lead powder and carbon material into the paste mixer and stir continuously for 9 minutes, then add 100 kg of pure water and stir for 3 minutes, and finally add dilute sulfuric acid and stir for 10 minutes, and set aside;

[0047] In the above step (3), the dilute sulfuric acid is added within 15-18 minutes; during the stirring process of the above step (3), the internal temperature of the paste machine is controlled between 65°C.

[0048] (4) filling and coating the lead paste after stirring in the step (3) on the polar pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com