Preparation method of longicorn trapping and killing agent

A contact and attractant technology, applied in the fields of attractant pests, botanical equipment and methods, insecticides, etc., can solve the problem of high labor cost, achieve fast knockdown, overcome insufficient release dose, and last for a long time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

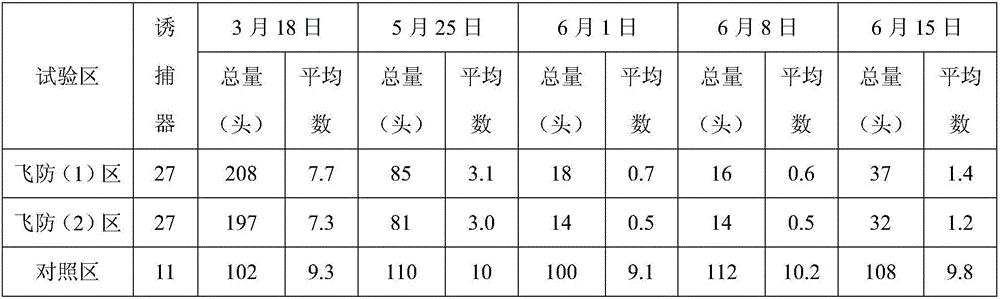

Examples

Embodiment 1

[0028] (1) 5 kilograms of myrcene are dissolved in 12 kilograms of xylenes to obtain attractant solution for subsequent use;

[0029] (2) Mix 0.6 kg of urea and 1.5 kg of formaldehyde, adjust the pH to 9 with ammonia water, stir and react at 60° C. at 60 rpm for 2 hours, and prepare the mixture of cystic wall prepolymer for later use. `

[0030] (3) Mix 1.5 kg of capsule wall prepolymer mixture, 0.2 kg of emulsifier and 10 kg of deionized water and stir at 130r / min for 5 minutes to form a uniform aqueous solution, then add 6 kg of attractant prepared in step (1) solution, with a high-speed shearing machine to shear 5min at a speed of 1500r / min to obtain an emulsion, wherein the emulsifier is calcium dodecylbenzenesulfonate and tristyrylphenol polyoxyethylene propylene ether with a mass ratio of 1:1 mixture.

[0031] (4) Transfer the obtained emulsion into an ordinary stirring tank, stir at a rotating speed of 130r / min, adjust the pH to 2 within 60 minutes with a 5% hydrochlo...

Embodiment 2

[0035] (1) 1.5 kilograms of α-pinene, 3.5 kilograms of β-pinene are dissolved in the attractant solution in 12 kilograms of toluene for subsequent use;

[0036] (2) Mix 1 kg of urea and 2.5 kg of formaldehyde, adjust the pH to 8 with ethanolamine, stir and react at 75° C. at 60 rpm for 2 hours, and prepare a mixture of cyst wall prepolymers for later use. `

[0037] (3) Mix 2 kg of capsule wall prepolymer mixture, 0.3 kg of emulsifier and 20 kg of deionized water, stir at 130r / min for 5 minutes to form a uniform aqueous solution, and then add 10 kg of lure prepared in step (1) The emulsifier solution was sheared at a speed of 800r / min for 3 minutes with a high-speed shearing machine to obtain an emulsion, wherein the emulsifier was calcium dodecylbenzenesulfonate and tristyrylphenol polyoxyethylene propylene with a mass ratio of 1:1 ether mixture.

[0038] (4) Transfer the obtained emulsion into an ordinary stirred tank, stir at a rotating speed of 130r / min, adjust the pH to...

Embodiment 3

[0042] (1) 1 kilogram of isophorone, 0.4 kilogram of dibutyl phthalate, 0.6 kilogram of diisobutyl phthalate are dissolved in the attractant solution in 6 kilograms of dimethylformamide for subsequent use;

[0043] (2) Mix 1.5 kg of urea and 3 kg of formaldehyde, adjust the pH to 8.5 with ammonia water, stir and react at 75° C. at a speed of 60 rpm for 2 hours, and prepare the cystic wall prepolymer mixture for later use. `

[0044] (3) Mix 2.8 kg of capsule wall prepolymer mixture, 0.5 kg of emulsifier and 30 kg of deionized water, stir at 130r / min for 5 minutes to form a uniform aqueous solution, and then add 14 kg of lure prepared in step (1) The emulsifier solution was sheared at a speed of 1500r / min for 5 minutes with a high-speed shearing machine to obtain an emulsion, wherein the emulsifier was calcium dodecylbenzenesulfonate and tristyrylphenol polyoxyethylene propylene with a mass ratio of 1:1 ether mixture.

[0045] (4) Transfer the obtained emulsion into an ordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com