Preparation method of cured soft pellet creep feed

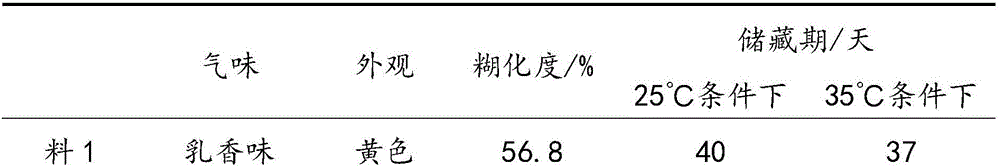

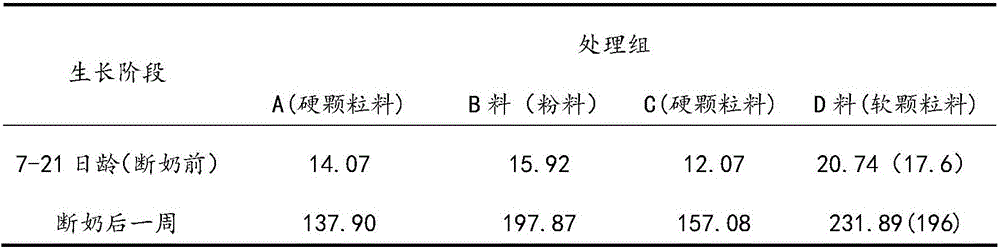

A technology of soft granules and trough feed, applied in the field of feed, can solve the problems of short storage time, harsh storage conditions, increased transportation and storage costs, etc., and achieve the effect of short production process, simple operation control and good palatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Add 0.2 parts of compound acidifier into warm water at a temperature of 60°C. The mass composition of warm water is 24 parts. After fully mixing, add it to 100 parts of powder, and put it in the kneading surface Stir in the machine for 10 minutes, the powder is evenly stirred, that is, there are no spherical particles.

[0027] Step 2: Under stirring, heat up the material obtained in step 1 in a three-stage manner while stirring, first raise the temperature to 60°C, keep it for 25-30s, then raise the temperature to 90°C, keep it for 20-25s, and finally raise the temperature to 120°C, keep it for 15s ~20s to get the cooked material;

[0028] Step 3: Extrude the cooked material into thin strips through an extrusion device, then cut into granules with a particle size of 2mm, and spread the granules to cool for later use; mix 0.03 parts of α-amylase and 0.2 parts of β-amylase Mix with 1 part of humectant (D-sorbitol) to make an aqueous solution, spray evenly on the...

Embodiment 2

[0031] Step 1: Add 0.3 parts of compound acidifier into warm water at a temperature of 60°C. The mass composition of warm water is 24 parts. After fully mixing, add it to 100 parts of powder, and put it in the kneading surface Stir in the machine for 10 minutes, the powder is evenly stirred, that is, there are no spherical particles.

[0032]Step 2: Under stirring, heat up the material obtained in step 1 in a three-stage manner while stirring, first raise the temperature to 60°C, keep it for 25-30s, then raise the temperature to 90°C, keep it for 20-25s, and finally raise the temperature to 120°C, keep it for 15s ~20s to get the cooked material;

[0033] Step 3: Extrude the cooked material into thin strips through an extrusion device, then cut into granules with a particle size of 2mm, and spread the granules to cool for later use; mix 0.03 parts of α-amylase and 0.2 parts of β-amylase Mix with 1 part of humectant (D-sorbitol) to make an aqueous solution, spray evenly on the ...

Embodiment 3

[0036] Step 1: Add 0.3 parts of compound acidifier into warm water at a temperature of 60°C. The mass composition of warm water is 26 parts. After fully mixing, add it to 100 parts of powder, and put it in the kneading surface Stir in the machine for 10 minutes, the powder is evenly stirred, that is, there are no spherical particles.

[0037] Step 2: Under stirring, heat up the material obtained in step 1 in a three-stage manner while stirring, first raise the temperature to 45°C, keep it for 25-30s, then raise the temperature to 65°C, keep it for 20-25s, and finally raise the temperature to 95°C, keep it for 15s ~20s to get the cooked material;

[0038] Step 3: Extrude the cooked material into thin strips through an extrusion device, then cut into granules with a particle size of 2mm, and spread the granules to cool for later use; mix 0.03 parts of α-amylase and 0.2 parts of β-amylase Mix with 1 part of humectant (D-sorbitol) to make an aqueous solution, spray evenly on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com