Sandwich-type composite hollow sphere and layer-by-layer cladding method for manufacturing same

A composite material and sandwich-type technology, applied in the direction of synthetic resin layered products, laminated, layered products, etc., can solve the problems of reduced work efficiency, scrapped finished products, increased scrapped rate, etc., to achieve reduced scrapped rate, high strength/ Density ratio, good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

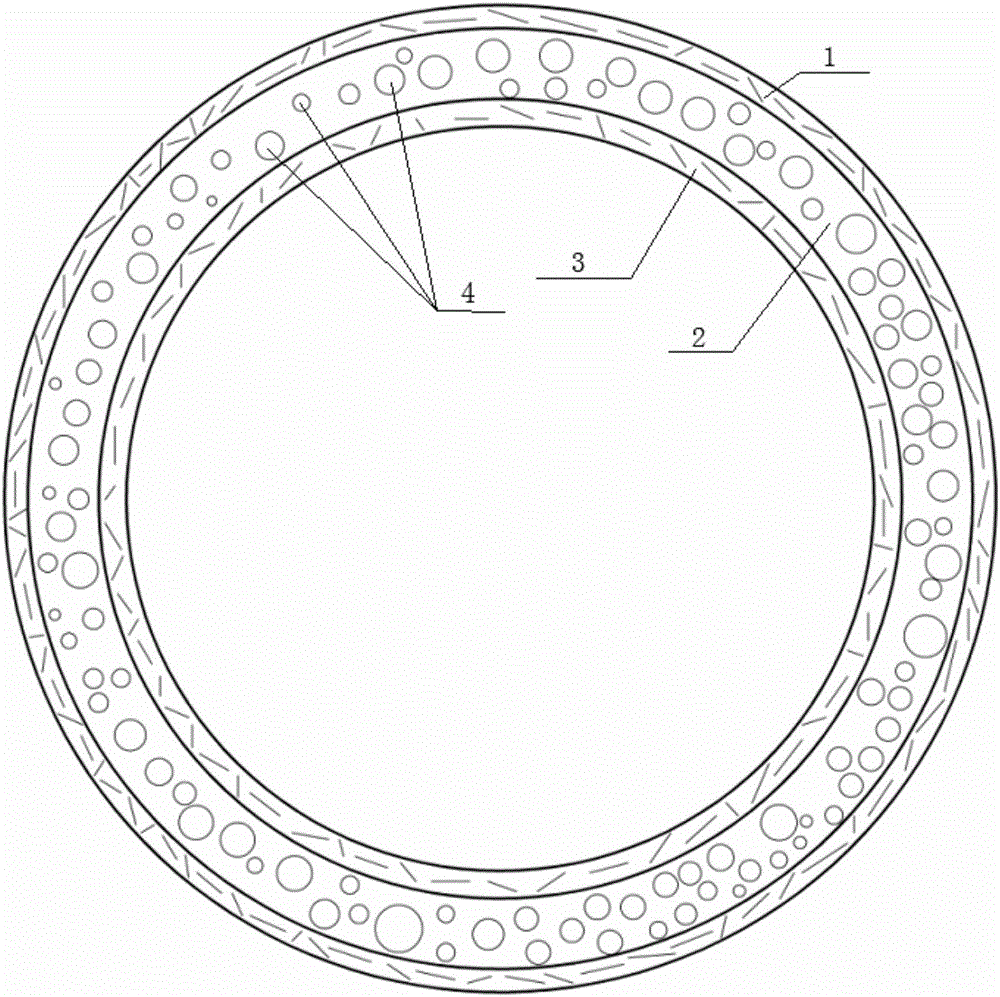

[0034] Such as figure 1 Shown: a sandwich-type hollow sphere of composite material, which sequentially includes an outermost layer 1, an intermediate layer 2 and an innermost layer 3 interconnected from outside to inside, and the intermediate layer 2 is filled with hollow glass beads 4.

[0035] The intermediate layer 2 is made of thermosetting epoxy resin.

[0036] The outermost layer 1 and the innermost layer 3 are made of thermosetting polyimide.

[0037] Both the outermost layer 1 and the innermost layer 3 are filled with reinforcements, and the reinforcements are carbon fibers.

[0038] The diameter of the hollow sphere is 2 mm, the thickness of the middle layer 2 is 0.1 mm, and the true density is 100 kg / m 3 , The hydrostatic pressure strength is 1MPa.

[0039] The true density of the hollow glass microsphere 4 is 100kg / m 3 , the hydrostatic pressure strength is 3 MPa, and the diameter is 10 microns.

[0040] The ratio of the total volume of the hollow glass microsp...

Embodiment 2

[0060] Such as figure 1 Shown: a sandwich-type hollow sphere of composite material, which sequentially includes an outermost layer 1, an intermediate layer 2 and an innermost layer 3 interconnected from outside to inside, and the intermediate layer 2 is filled with hollow glass beads 4.

[0061] The middle layer 2 is made of thermosetting polyimide.

[0062] The outermost layer 1 and the innermost layer 3 are made of thermosetting polypropylene.

[0063] The outermost layer 1 is filled with reinforcement, the innermost layer 3 is not filled with reinforcement, and the reinforcement is glass fiber.

[0064] Its diameter is 60 mm, the thickness of the middle layer 2 is 10 mm, and its true density is 800 kg / m 3 , The hydrostatic pressure strength is 80 MPa.

[0065] The true density of the hollow glass microsphere 4 is 500 kg / m 3 , the hydrostatic pressure strength is 250 MPa, and the diameter is 100 microns.

[0066] The ratio of the total volume of the hollow glass microsp...

Embodiment 3

[0085] Such as figure 1 Shown: a sandwich-type hollow sphere of composite material, which sequentially includes an outermost layer 1, an intermediate layer 2 and an innermost layer 3 interconnected from outside to inside, and the intermediate layer 2 is filled with hollow glass beads 4.

[0086] The middle layer 2 is made of thermosetting polypropylene.

[0087] The outermost layer 1 and the innermost layer 3 are made of thermosetting epoxy resin.

[0088] The innermost layer 3 is filled with reinforcement, the outermost layer 1 is not filled with reinforcement, and the reinforcement is acicular wollastonite.

[0089] Its diameter is 30 mm, the thickness of the middle layer 2 is 5 mm, and its true density is 400 kg / m 3 , The hydrostatic pressure strength is 40 MPa.

[0090] The true density of the hollow glass microspheres 4 is 200 kg / m 3 , the hydrostatic pressure strength is 100MPa, and the diameter is 40 microns.

[0091] The ratio of the total volume of the hollow gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com