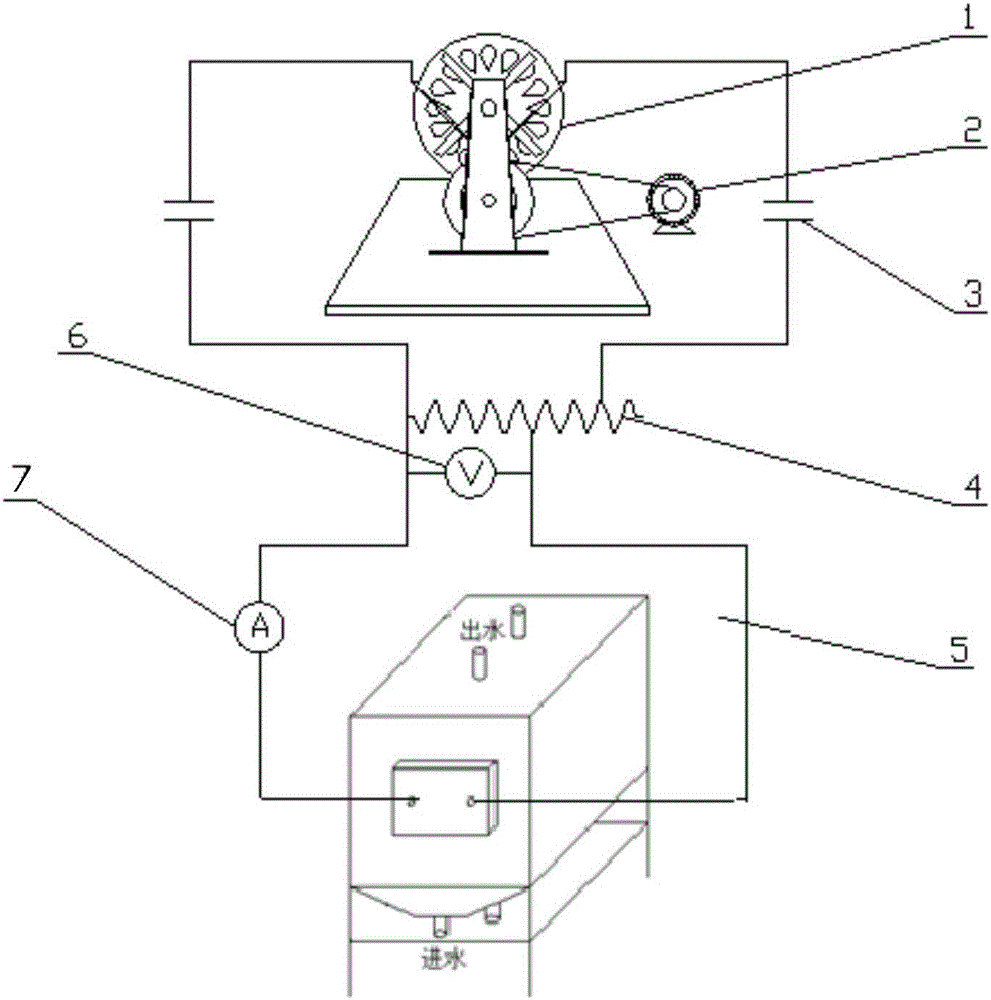

Electrocatalytic oxidation device running under ultrahigh voltage condition and process method

An electrocatalytic oxidation and ultra-high voltage technology, which is applied in the professional field of environmental engineering, can solve the problems of high energy consumption and low treatment efficiency of the electrocatalytic oxidation process, achieve the effects of small operating current, improve current utilization efficiency, and avoid short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

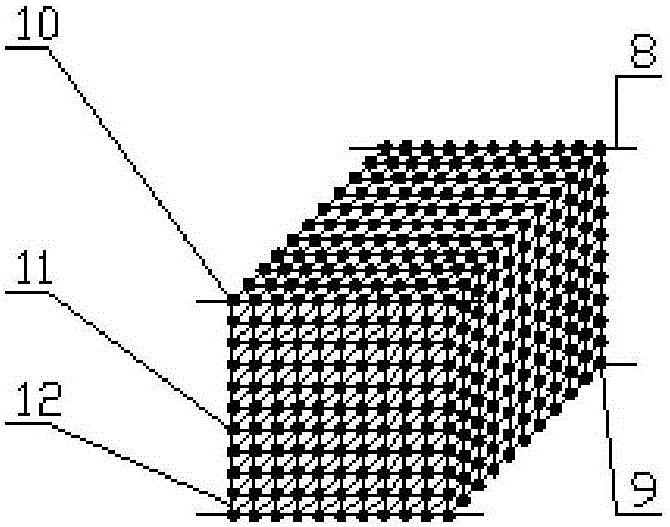

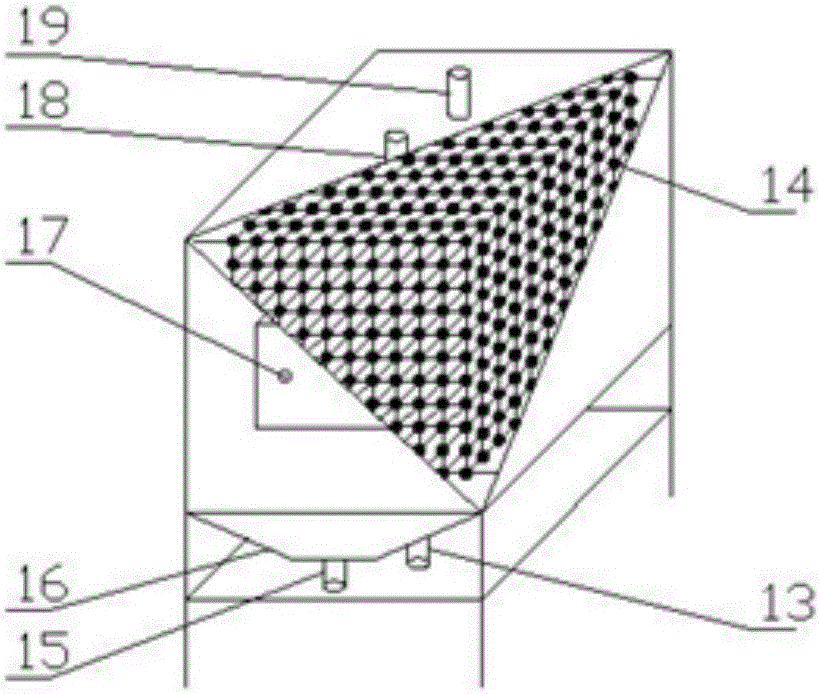

Method used

Image

Examples

example 1

[0037] A petrochemical company in Hebei Province contained a large amount of refractory substances in the production wastewater due to the complexity of the refined oil products. The COD of the wastewater was about 80mg / L after biochemical treatment, which could not meet the relevant effluent discharge standards. The engineering application research on the advanced treatment of the company's biochemical effluent was carried out by using an electrocatalytic oxidation device operating under ultra-high voltage conditions. The results show that when the operating voltage is 36000V, the operating current is 10mA, the hydraulic retention time is 30min, and the effluent COD≤60mg / L, the effluent meets the standard discharge water quality requirements. At this time, the current efficiency is 55%. Compared with the traditional two-dimensional electrolysis equipment, the power consumption per ton of water is reduced by about 0.9kw.h under the condition that the treatment effect remains th...

example 2

[0039] After biochemical treatment of pharmaceutical wastewater from a factory in Tianjin, in order to achieve near-zero discharge of wastewater, an ultrafiltration-reverse osmosis double-membrane system was used to reuse part of the biochemical effluent. After being treated by the double-membrane system, a certain amount of concentrated liquid will be produced. 90mg / L, conductivity about 1000-5000μs / cm, Cl - The content is about 700-900mg / L. The concentrated solution is not suitable for further biochemical treatment due to its small displacement and the difficulty of biochemical degradation of the contained substances. After being treated with an electrocatalytic oxidation device operating under ultra-high voltage conditions, when the operating voltage is 50,000V, the operating current is 10-15mA, the hydraulic retention time in the reactor is 30min, and the effluent COD≤50mg / L, it meets the standard discharge water quality It is required that the current efficiency at this t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com