Compound containing 1,2,4-triazine group and organic electroluminescence device of compound

A technology of triazine groups and compounds, which is applied in the field of organic electroluminescent compounds and organic electroluminescent devices, can solve the problems of easy crystallization, low electron mobility, low electron mobility, etc. of organic materials, and achieve electroluminescence. The effect of good luminous efficiency, high luminous purity and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Synthesis of compound 5

[0059]

[0060] In a three-necked flask, add intermediate A (1.9g, 5mmol), 9-benzene-10-anthracene boronic acid (1.5g, 5mmol), potassium carbonate (1.38g, 10mmol), tetrakistriphenylphosphine palladium (50mg), Tetrahydrofuran (20ml) and water (10ml) were heated to reflux for 10 hours under nitrogen protection, cooled, extracted with dichloromethane, the organic layer was dried and concentrated, and the crude product was purified by column chromatography to obtain 2.1g of product with a yield of 75%.

Embodiment 2

[0062] Synthesis of Compound 12

[0063]

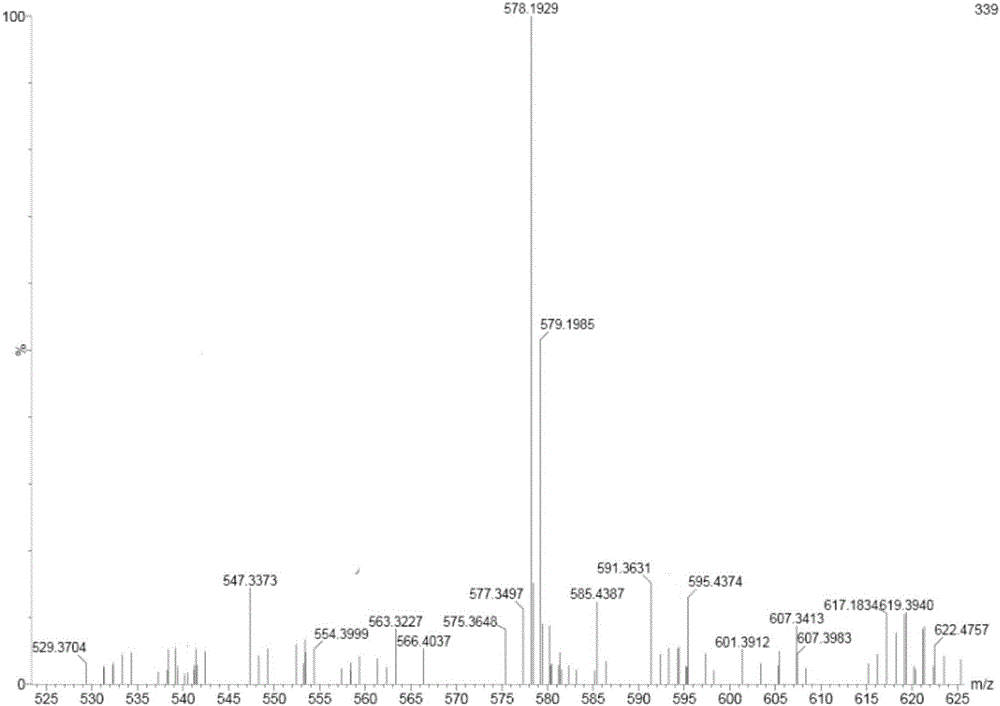

[0064] The synthesis method is the same as that of compound 5, except that B-[4-(1-phenyl-1H-benzimidazol-2-yl)phenyl]-boronic acid is used instead of 9-benzene-10-anthracene boronic acid, and the yield is 64% . Its NMR such as figure 1 shown.

Embodiment 3

[0066] Synthesis of Compound 20

[0067]

[0068] The synthesis method was the same as that of compound 5, except that 4-(9H-carbazolyl)-phenylboronic acid was used instead of 9-benzene-10-anthraceneboronic acid, and the yield was 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com