Method for preparing rubber by using onion essential oil as rubber regenerant

The technology of onion essential oil and rejuvenating agent is applied in the field of rubber application, which can solve the problems of poor environmental protection effect, waste of resources, and difficulty in reuse, and achieve the effects of reduced energy consumption, good controllability and obvious regeneration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

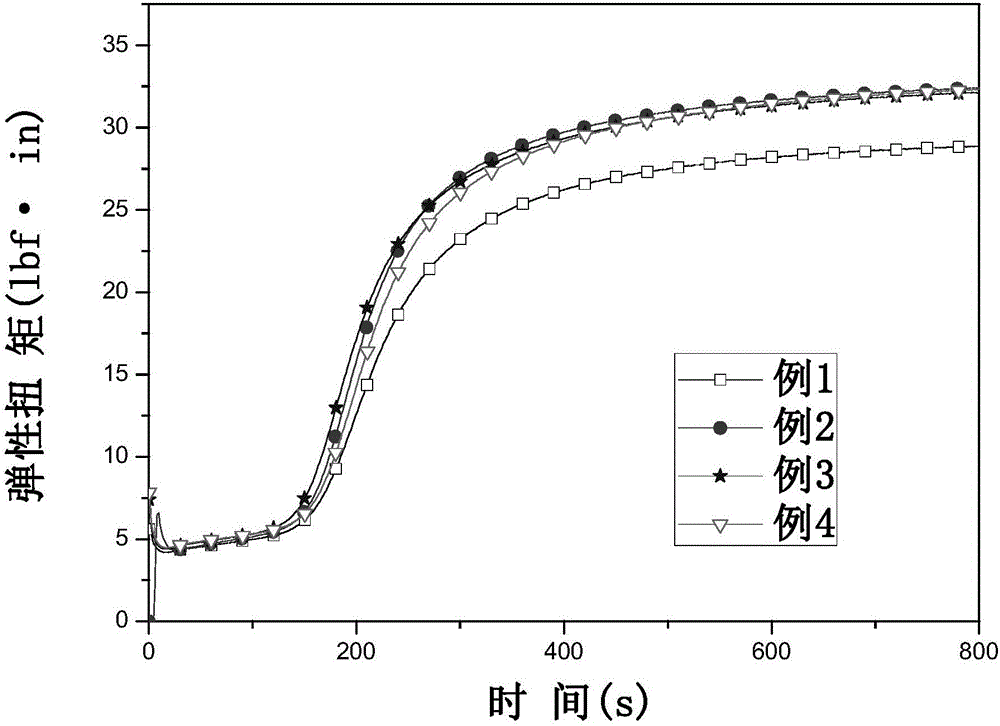

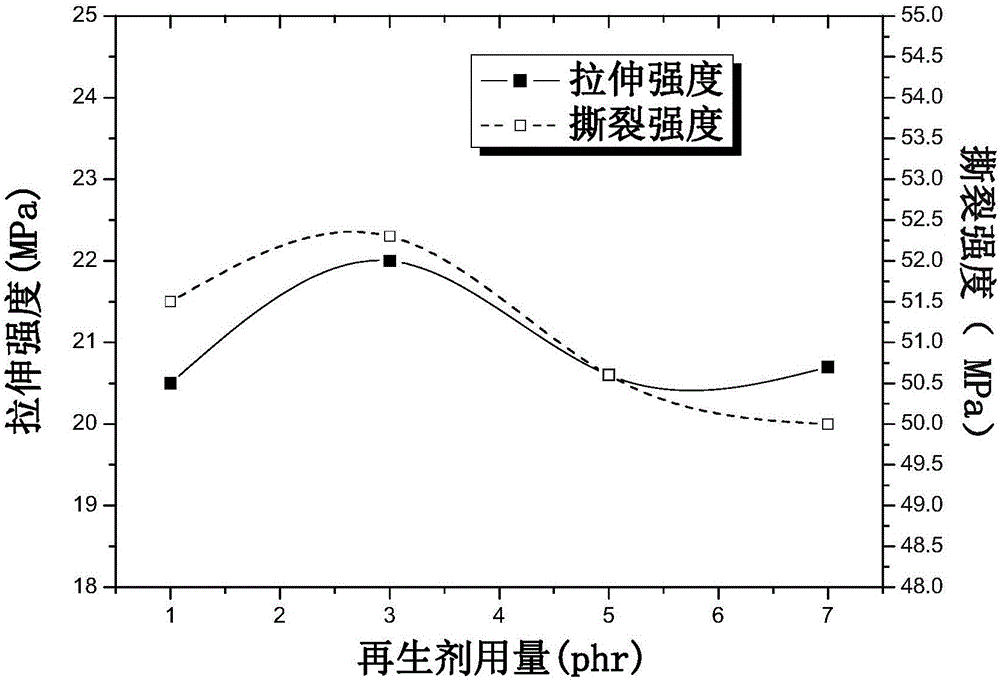

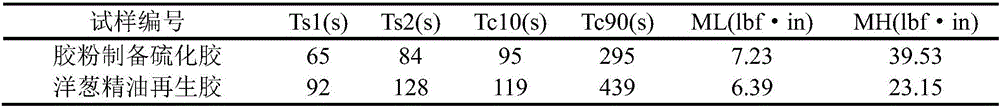

[0029] (1) Preparation of reclaimed rubber: 1 part by mass of onion essential oil is mixed into 100 parts by mass of shoe sole rubber powder, and after mixing, it is directly placed on a double-roll mill for several times to obtain reclaimed rubber;

[0030] (2) Preparation of rubber compound: 100 parts by mass of styrene-butadiene rubber was masticated to cover rolls on a two-roll mill, and then 5 parts by mass of reclaimed rubber was added. After mixing evenly, add 5 parts by mass of zinc oxide, 1 part by mass of stearic acid, 1 part by mass of antioxidant RD, 45 parts by mass of carbon black N220, and finally add 1.7 parts by mass of accelerator CZ, 2 parts by mass of accelerator Agent D, 1.4 parts by mass of sulfur, mixed evenly, and thinly passed through the sheet, to obtain the rubber compound;

[0031] (3) Preparation of vulcanized rubber: after parking the mixed rubber for 16 hours, measure the positive vulcanization time t90 at 150°C with a UR2030 vulcanizer, and fina...

Embodiment 2

[0033] (1) Preparation of reclaimed rubber: 3 parts by mass of onion essential oil was mixed into 100 parts by mass of shoe sole rubber powder, and after mixing, it was directly placed on a double-roll mill for several times to obtain reclaimed rubber;

[0034] (2) Preparation of rubber compound: 100 parts by mass of styrene-butadiene rubber was masticated to cover rolls on a two-roll mill, and then 10 parts by mass of reclaimed rubber was added. After mixing evenly, add 5 parts by mass of zinc oxide, 1 part by mass of stearic acid, 1 part by mass of antioxidant RD, 45 parts by mass of carbon black N220 in sequence, and finally add 1.7 parts by mass of accelerator CZ, 2 parts by mass of accelerator Agent D, 1.4 parts by mass of sulfur, mixed uniformly, and thinly passed out to obtain a rubber compound;

[0035] (3) Preparation of vulcanized rubber: after parking the mixed rubber for 16 hours, measure the positive vulcanization time t90 at 150°C with a UR2030 vulcanizer, and fi...

Embodiment 3

[0037] (1) Preparation of reclaimed rubber: 5 parts by mass of onion essential oil was mixed into 100 parts by mass of rubber powder for sole rubber, and after mixing, it was directly placed on a double-roller mill for several times to obtain reclaimed rubber;

[0038](2) Preparation of rubber compound: 100 parts by mass of styrene-butadiene rubber was masticated to cover rolls on a two-roll mill, and then 15 parts by mass of reclaimed rubber was added. After mixing evenly, add 5 parts by mass of zinc oxide, 1 part by mass of stearic acid, 1 part by mass of antioxidant RD, 45 parts by mass of carbon black N220, and finally add 1.7 parts by mass of accelerator CZ, 2 parts by mass of accelerator Agent D, 1.4 parts by mass of sulfur, mixed evenly, and thinly passed through the sheet, to obtain the rubber compound;

[0039] (3) Preparation of vulcanized rubber: after parking the mixed rubber for 16 hours, measure the positive vulcanization time t90 at 150°C with a UR2030 vulcanize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com