Aluminum alloy polishing solution and preparation method thereof

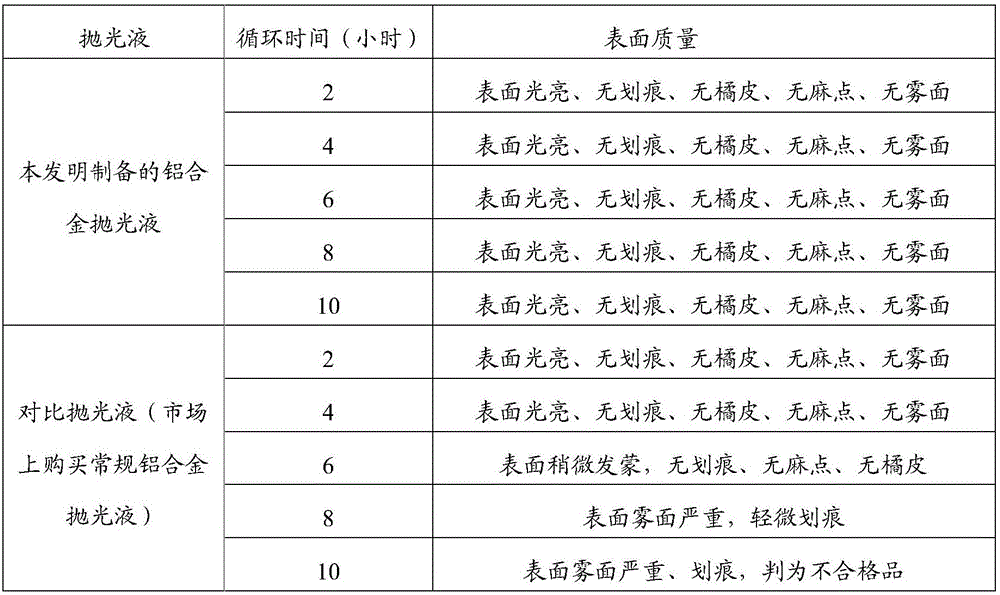

A technology of polishing liquid and aluminum alloy, which is applied in the field of metal polishing liquid, can solve the problems of short service time and poor polishing effect, and achieve the effects of ensuring uniformity, improving smoothness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a method for preparing the above-mentioned aluminum alloy polishing solution, which comprises the following proportions: 30%-50% of silica sol, 0.5%-3% of complexing agent, 0.02%-0.1% of surfactant, corrosion inhibitor 0.05%-0.5%, and brightener 0.5-2%, and the rest is water; the particle diameter of the silica sol is 80-140 nanometers, and the concentration is 30%-50%. Take each component and adopt at least the following steps:

[0026] a, add described surfactant in described silica sol, stir evenly;

[0027] B, add described complexing agent in the mixture obtained in step a, stir;

[0028] c. Add the corrosion inhibitor to the mixture obtained in step b, and stir evenly;

[0029] d. Add a brightener to the mixture obtained in step c, stir evenly, and perform circulation filtration with a filter to obtain the silicon oxide polishing solution.

[0030] Further, for the limitation of step d of the above-mentioned preparation method...

Embodiment 1

[0033] An aluminum alloy polishing solution, the aluminum alloy polishing solution comprises the following components: 30% of silica sol, 0.5% of complexing agent, 0.02% of surfactant, 0.05% of corrosion inhibitor, and 0.5% of brightener, and the rest is Water; the particle diameter of the silica sol is 80 nanometers, and the concentration is 30%.

[0034] Further, the aluminum alloy polishing liquid in the present invention, as a further limitation on the complexing agent, the complexing agent adopts hexamethylenediamine, trihexanolamine, disodium edetate A mixture of one or more.

[0035] Further, the aluminum alloy polishing liquid in the present invention, as another optional limitation on the complexing agent therein, the complexing agent adopts a mixture of one or more including glycine and citric acid.

[0036] Further, the aluminum alloy polishing liquid in the present invention, as a further definition of the surfactant, the surfactant includes sodium dodecylbenzenes...

Embodiment 2

[0040]An aluminum alloy polishing solution, the aluminum alloy polishing solution comprises the following components: 35% of silica sol, 1.5% of complexing agent, 0.05% of surfactant, 0.2% of corrosion inhibitor, and 0.8% of brightener, and the rest is Water; the particle size of the silica sol is 90 nanometers, and the concentration is 35%.

[0041] Further, the aluminum alloy polishing liquid in the present invention, as a further limitation to the complexing agent therein, the complexing agent adopts hexamethylenediamine, trihexanolamine, disodium edetate A mixture of one or more.

[0042] Further, the aluminum alloy polishing liquid in the present invention, as another optional definition of the complexing agent, uses a mixture of one or more of the complexing agents including glycine and citric acid.

[0043] Further, the aluminum alloy polishing liquid in the present invention, as a further definition of the surfactant, the surfactant includes sodium dodecylbenzenesulfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com