Three-layer mesh fabric and flexible shaping treatment method thereof

A technology of three-layer mesh and processing method, which is applied in the textile field, can solve problems such as weak bonding force between the adhesive layer and mesh, mesh fusing, easy aging and degumming, etc., to solve fusing and discoloration, easy to control, and controllable range big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

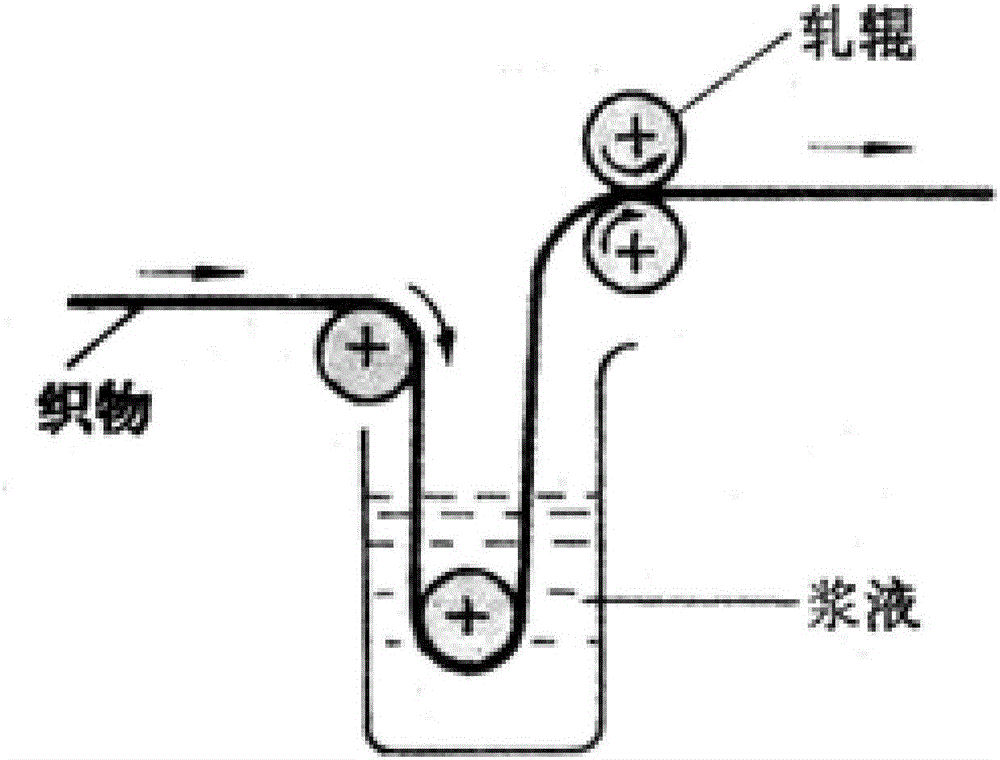

Method used

Image

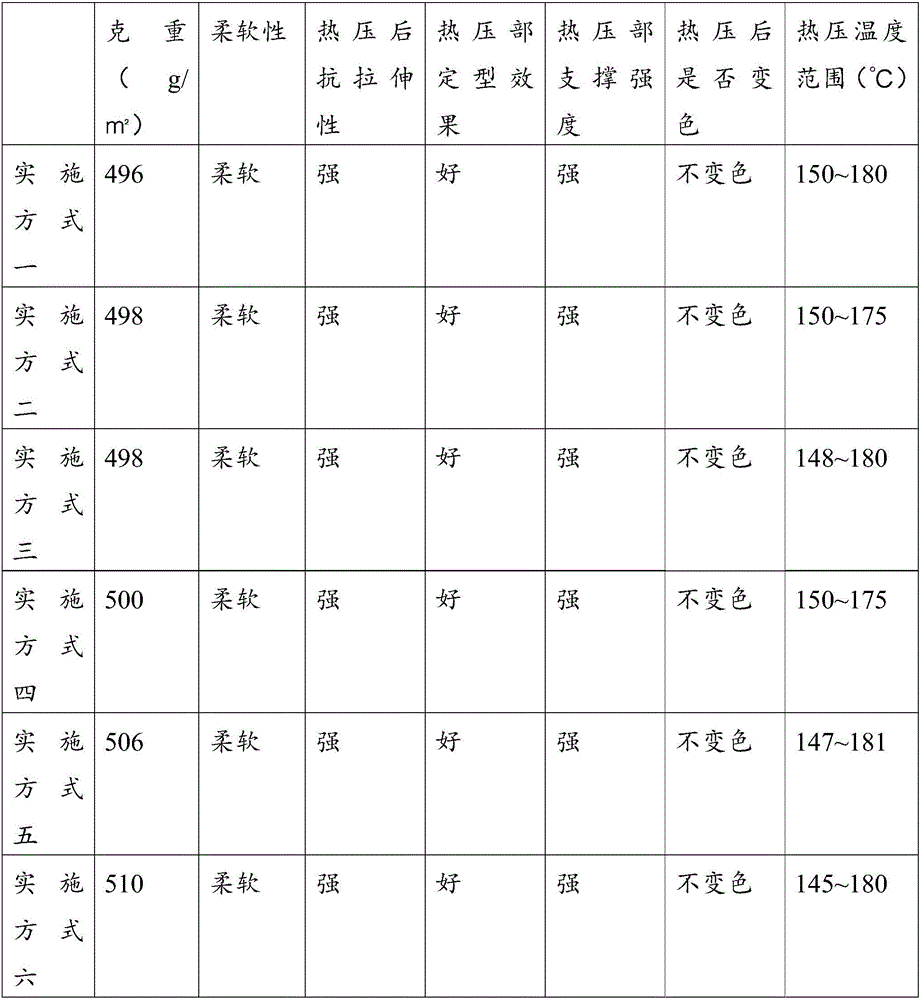

Examples

Embodiment approach 1

[0048] The three-layer mesh is subjected to padding treatment, the padding solution used in the padding treatment is a water-based polyurethane solution with a concentration of 10% by mass, and after the padding treatment, the three-layer mesh is partially treated with a hot pressing temperature of 170 degrees Celsius. Heat press setting treatment.

[0049] Among them, water-based polyurethane is a new type of polyurethane system that uses water instead of organic solvents as the dispersion medium, also known as water-dispersed polyurethane, water-based polyurethane or water-based polyurethane;

[0050] According to particle size and appearance, it can be divided into polyurethane aqueous solution (particle size0.1 micron, appearance cloudy);

[0051] What is used in this embodiment is a 5-200 micron polyurethane emulsion.

[0052] According to whether the side chain or the main chain of the polyurethane molecule contains ionic groups, that is, whether it is an ionomer (iono...

Embodiment approach 2

[0059] The difference with Embodiment 1 is that in this embodiment, the padding solution is an aqueous polyurethane solution with a mass percentage concentration of 20%, the particle diameter of the aqueous polyurethane solution is 5um, and the temperature of the aqueous polyurethane solution is 40 degrees Celsius. The soaking time of the first layer of mesh in the aqueous polyurethane solution is 3 minutes, and the dry pressure of the three-layer mesh is 450N / cm;

[0060] The drying temperature of the three-layer mesh cloth is 110 degrees Celsius;

[0061] The temperature of the hot-pressing die head is 160 degrees centigrade when the three-layer mesh cloth is hot-pressed and shaped.

Embodiment approach 3

[0063] The difference from Embodiment 1 is that in this embodiment, the padding solution is an aqueous polyurethane solution with a mass percent concentration of 30%, the particle diameter of the aqueous polyurethane solution is 100 um, and the temperature of the aqueous polyurethane solution is 45 degrees Celsius. The soaking time of the first layer of mesh in the aqueous polyurethane solution is 3 minutes, and the dry pressure of the three-layer mesh is 460N / cm;

[0064] The drying temperature of the three-layer mesh cloth is 120 degrees Celsius;

[0065] The temperature of the hot-pressing die head is 165 degrees centigrade when the three-layer mesh cloth is hot-pressed and shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com