Hot press installation method of engine gas mixer and cam structure

A gas mixer and engine technology, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of easily damaged cam devices, bulky, and insufficient precision in controlling the opening of the oil needle, so as to achieve no position change, Safe and reliable operation, the effect of optimal idle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

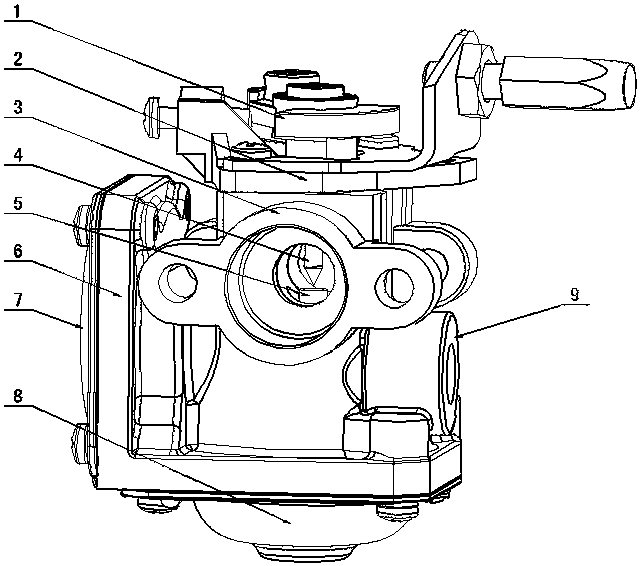

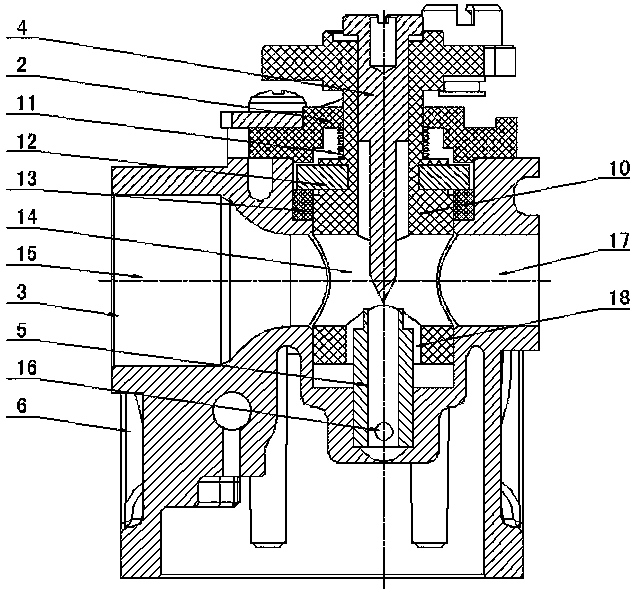

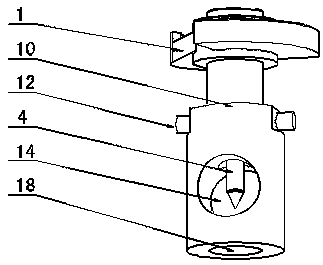

[0020] figure 1 with figure 2 As shown, the present invention creates a specific embodiment of the engine gas mixer, which includes a housing 6, a gland 2, a throttle plunger assembly, and the housing 6 is provided with a venturi tube 3, a high-pressure chamber 7, The low-pressure chamber 8 and the air intake chamber 9, the throttle plunger assembly is installed on the plunger installation hole of the housing 6 through the gland 2, and the throttle plunger assembly includes the throttle plunger 10, left and right guide posts 12. Oil needle 4, the throttle plunger 10 is provided with a plunger vent hole 14 matched with the venturi tube 3 and forms a rotary valve with the venturi tube 3, and the oil needle 4 is fixed in the center hole of the throttle plunger 10 Above, the left and right guide posts 12 are symmetrically fixed on both sides of the throttle plunger 10, and a cam structure 13 is fixed on the plunger mounting hole of the housing 6 through interference fit, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com