Carriage slide valve and transfer pump and pump truck with same

A technology for conveying pumps and carriages, which is applied in the direction of sliding valves, parts of pumping devices for elastic fluids, valve devices, etc., and can solve the problems of reduced reliability and service life, sealing performance affecting discharge pressure, and sliding rod sealing Reduced coaxiality and other problems to achieve the effect of improved reliability, reliable sealing and high coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

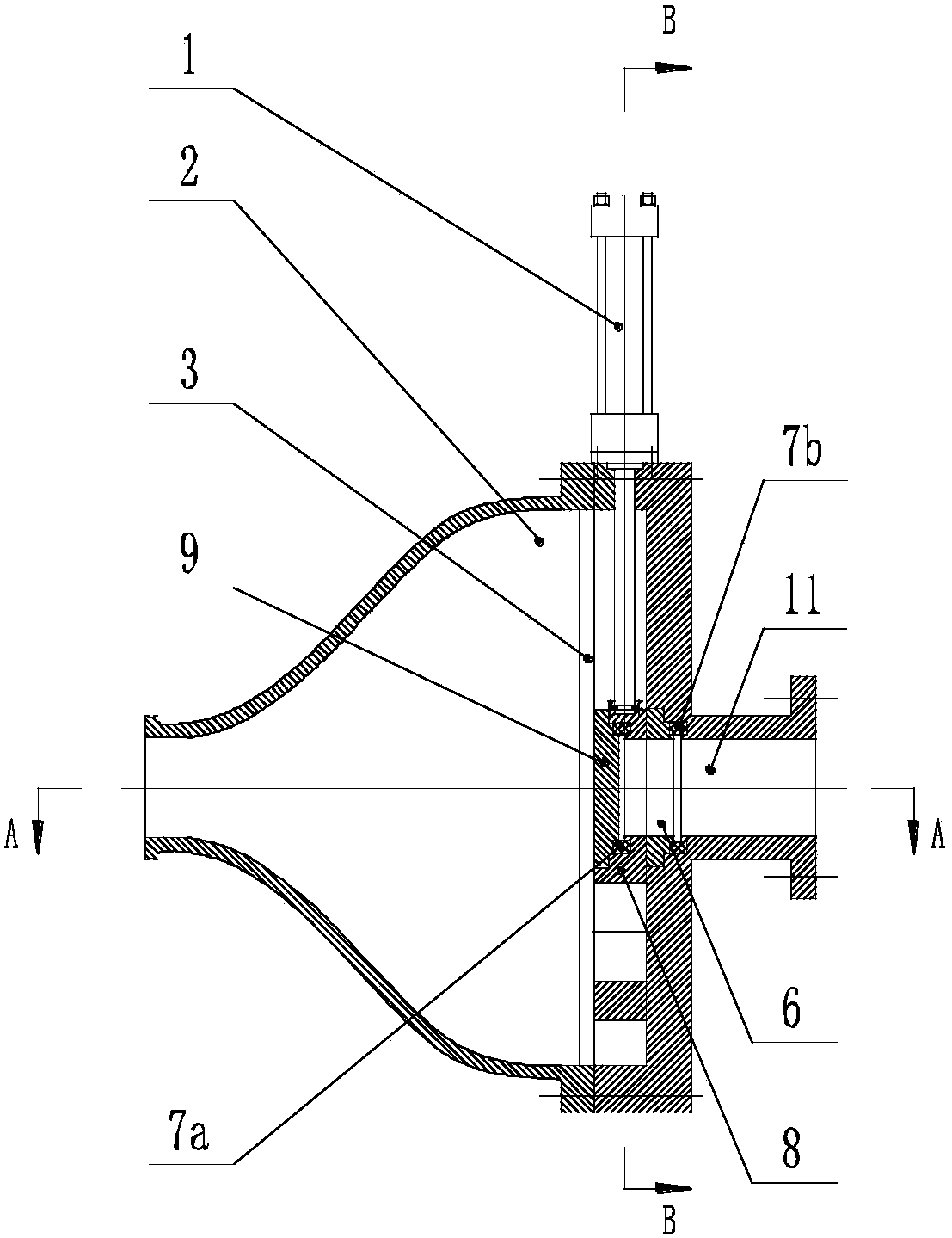

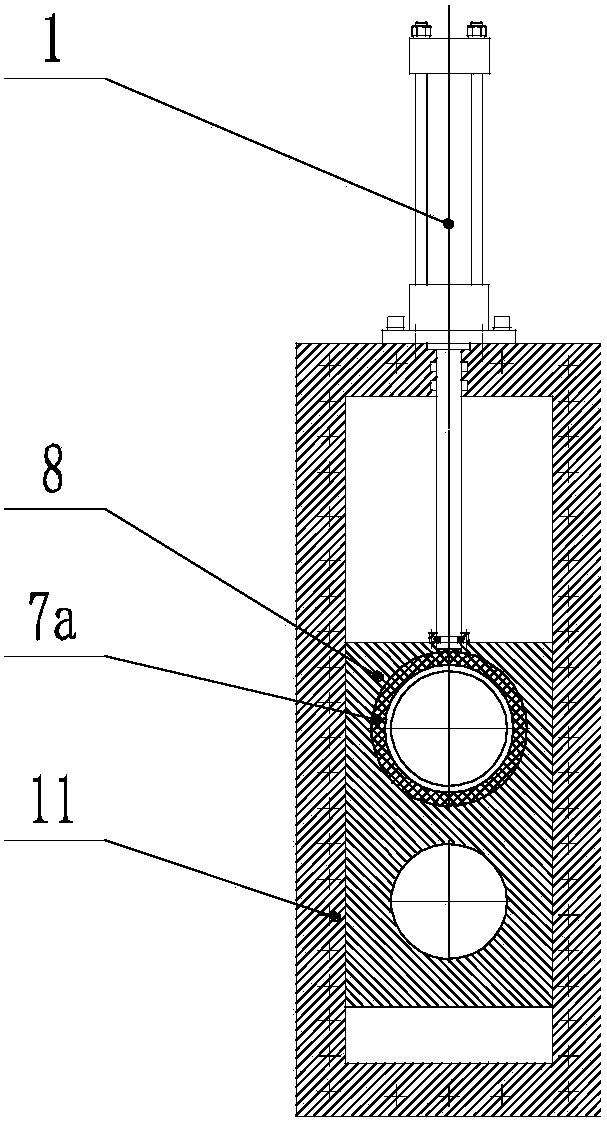

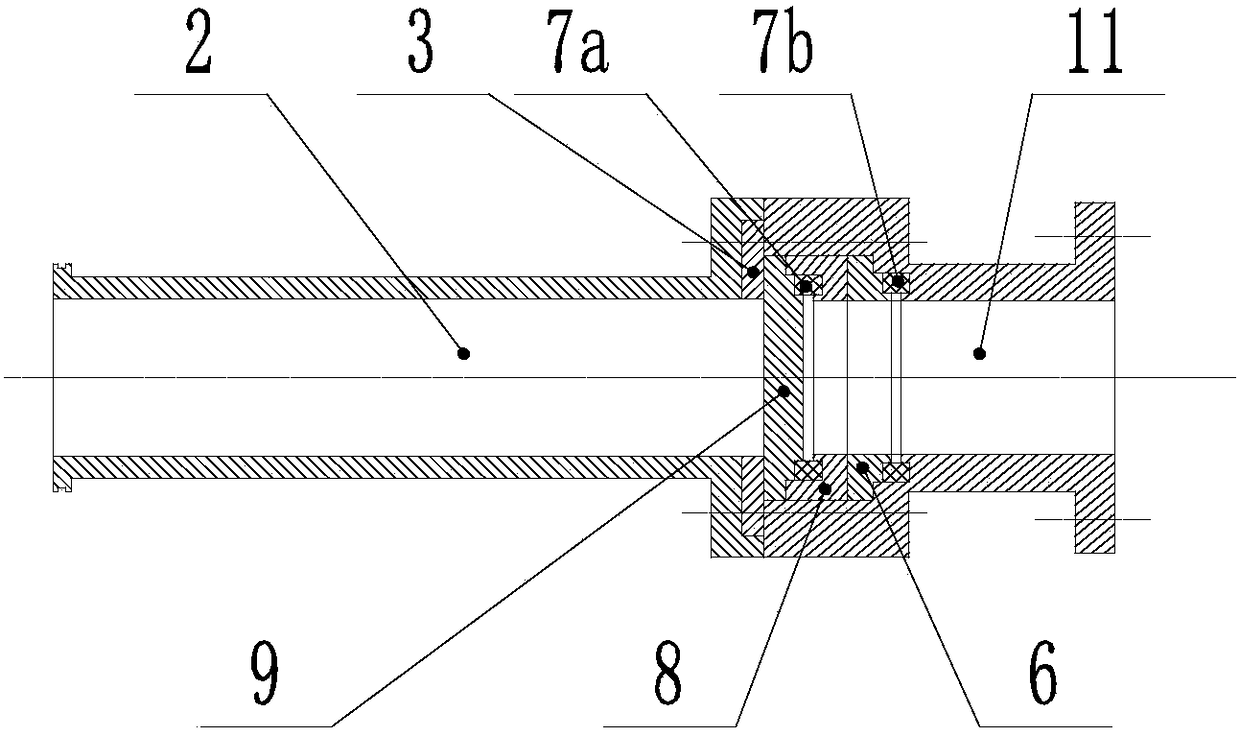

[0085] see figure 1 , figure 2 and image 3 , which shows a schematic diagram of a carriage slide valve according to a preferred embodiment of the present invention. The slide valve shown in the figure includes: a driving device 1, an auxiliary valve body 2, a sliding pressure plate 3, a through-hole body 6, a first elastic body 7a, a second elastic body 7b, a drag body 8, a valve plate 9, a main valve Body 11.

[0086] Wherein, there is a feed hole on the main valve body 11, and the material can pass through the feed hole of the main valve body 11; the through hole body 6 is provided with a through hole; the drag body 8 is provided with a mounting hole; the first elastic The body 7a and the second elastic body 7b are elastic seals with sealing function, which can be rubber seal rings, polyurethane seal rings or polytetrafluoroethylene seal rings, etc.; the driving device 1 is a hydraulic cylinder or an air cylinder.

[0087] The auxiliary valve body 2 and the main valve ...

Embodiment 2

[0093] see Figure 4 , Figure 5 and Figure 6 , which shows a schematic diagram of another preferred embodiment of the carriage slide valve of the present invention, the carriage slide valve includes: a driving device 1, an auxiliary valve body 2, a guide plate 4, a slide rod 5, a through-hole body 6, a first Elastic body 7a, second elastic body 7b, driving body 8, valve plate 9, main valve body 11.

[0094]Wherein, the main valve body 11 is provided with a feed hole, the drag body 8 is provided with an installation hole, the through hole body 6 is provided with a through hole, and the guide plate 4 is provided with a guide hole; the auxiliary valve body 2 and the main valve body 11 Installed together, the driving device 1 is connected with the main valve body 11, and the power output end of the driving device 1 is connected with two slide rods 5, and the two slide rods 5 are respectively installed in the guide holes of the two guide plates 4, and the guide plates 4 is loc...

Embodiment 3

[0100] see Figure 7 , Figure 8 , Figure 9 and Figure 10 , which shows a schematic diagram of another preferred embodiment of the carriage slide valve of the present invention, the carriage slide valve includes: a driving device 1, an auxiliary valve body 2, a sliding pressure plate 3, a guide plate 4, a slide rod 5, a through-hole body 6. Elastic body 7, drag body 8, valve plate 9, material passing plate 10, main valve body 11, main valve body 11 and auxiliary valve body 2 are connected.

[0101] The slide valve of this embodiment has two gate valve units, and the main valve body 11 has two material passing holes, and the two material passing holes belong to the two gate valve units, and each gate valve unit includes a driving device 1, Two sliding pressure plates 3, two guide plates 4, two sliding rods 5, a through hole body 6, an elastic body 7, a drag body 8, a valve plate 9 and a material passing plate 10.

[0102] The auxiliary valve body 2 is connected with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com