Metalized safety film layer stacked-type pulse capacitor

A technology of pulse capacitors and safety films, applied in film/thick film capacitors, laminated capacitors, capacitors, etc., can solve the problems of low labor efficiency, low qualification rate, and the plastic bracket of the capacitor core falls off, saving processing and The cost of materials, the improvement of space utilization, and the effect of increasing charge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be described below in conjunction with specific embodiments.

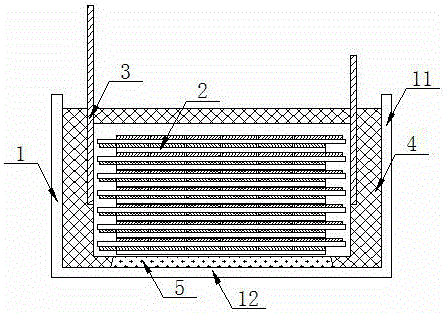

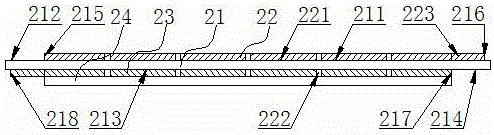

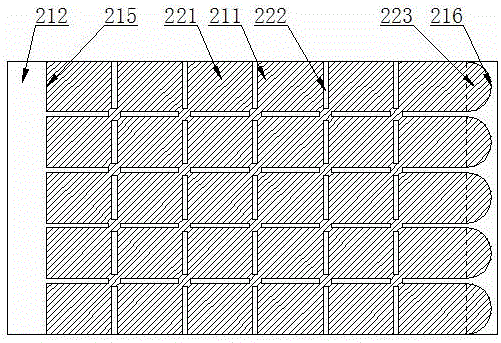

[0019] Such as Figure 1 to Figure 3 Shown is a structural schematic diagram of a metallized safety film laminated pulse capacitor according to the present invention.

[0020] A metallized safety film laminated pulse capacitor according to the present invention includes a capacitor core 2, a lead-out solder piece 3, a plastic shell 1 and a filling resin 4, the capacitor core 2 is arranged in the plastic shell 1, and The plastic shell 1 is filled with the filling resin 4, one end of the lead-out solder piece 3 is connected to the capacitor core 2, and the other end of the lead-out solder piece 3 is located outside the plastic shell 1; Fix the capacitor core 2 to the plastic glue 5 inside the plastic casing 1 . The plastic glue 5 can be but not limited to PVC glue, PP glue, PE glue, PU glue, ABS glue, TPR glue, 502 glue, plastic instant glue; specifically, preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com