Smart liquid for stripping photoresist

A photoresist and liquid technology, applied in the processing of photosensitive materials, non-ionic surface active compounds, anionic surface active compounds, etc., can solve the problems of high cost and complex free radical processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

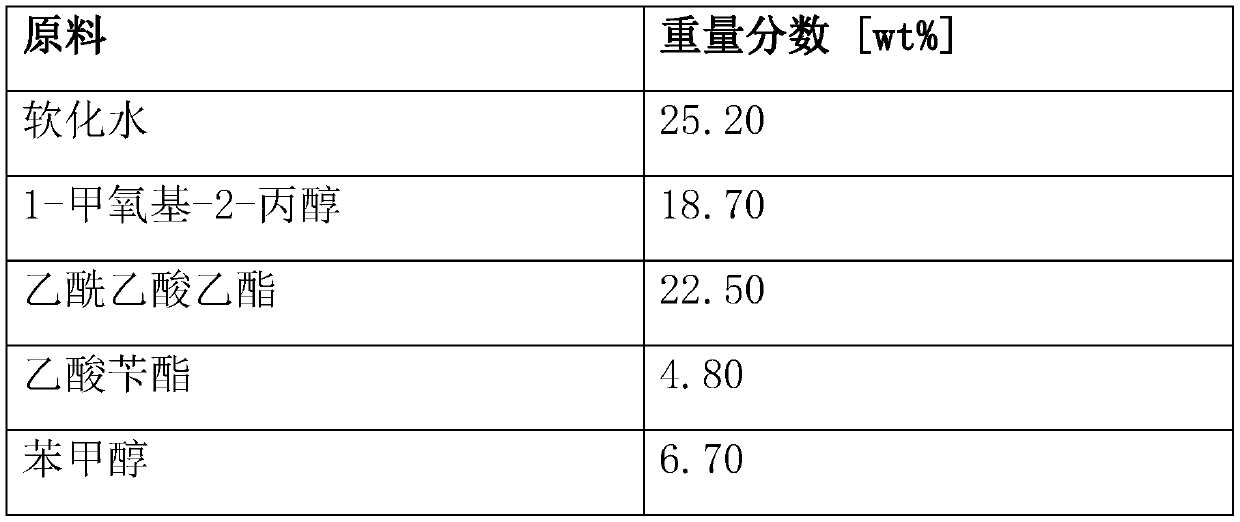

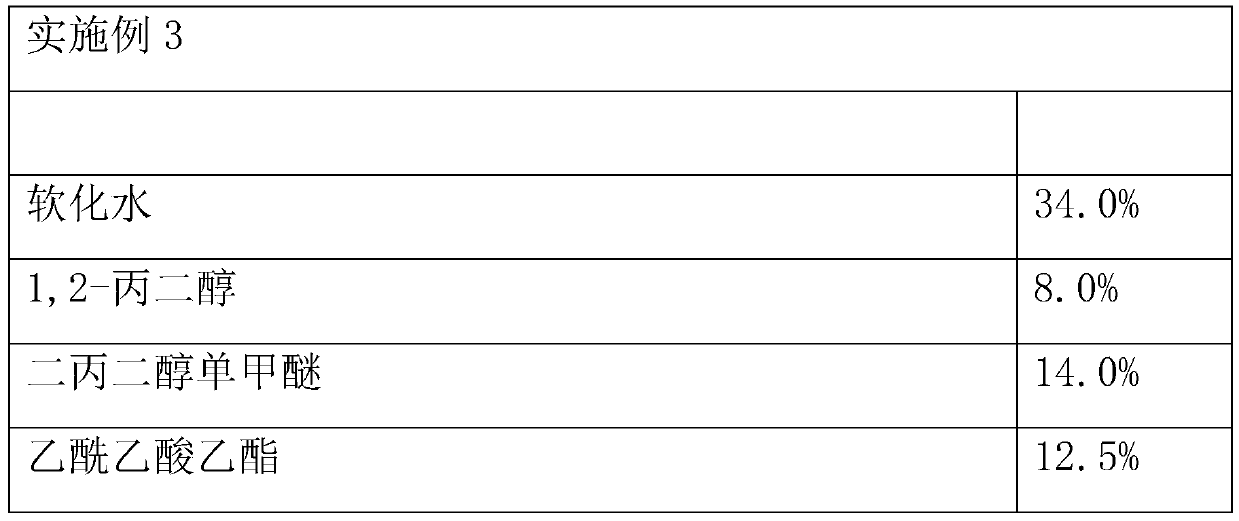

Examples

Embodiment 1

[0090]

[0091]

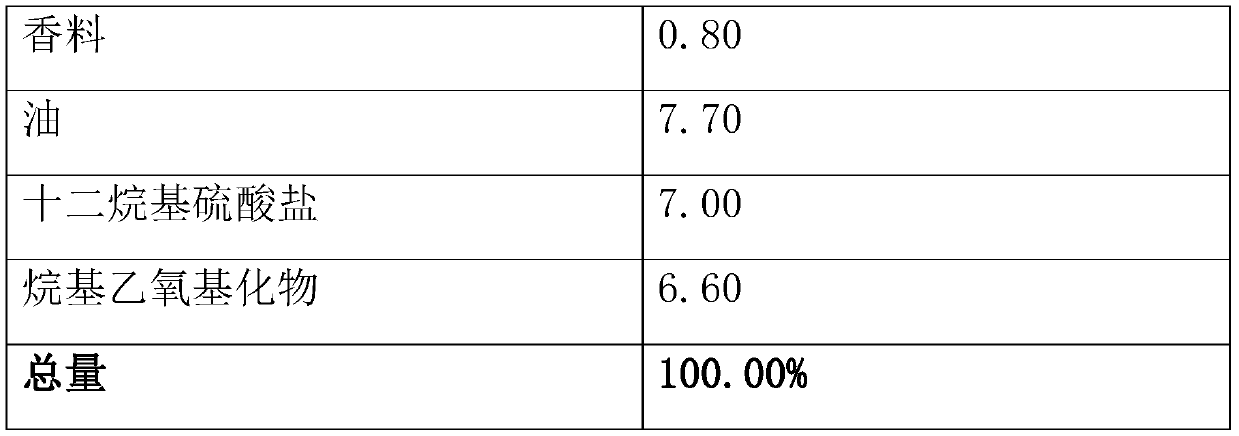

Embodiment 2

[0093] raw material Weight fraction [wt%] softened water 39.45 diacetone alcohol 14.00 ethyl acetoacetate 25.00 Oil 3.00 2-phenylethanol 3.75 Alkyl ethoxylates 12.00 lauryl sulfate 2.80 Total 100.00%

[0094]

[0095]

[0096] All heterogeneous systems had turbidity in the range of greater than 0 to less than or equal to 200 NTU. Turbidity can be maintained in a wide temperature range from 10°C to 95°C. Turbidity can be easily measured using a nephelometer, for example, a Hach 2100 nephelometer well known to those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com