Cleaning agent for automobile three-way catalyst

A three-way catalytic converter and cleaning agent technology, which is applied in the field of pollution treatment, can solve problems such as excessive exhaust gas, increased fuel consumption, and reduced power, and achieve the effects of reducing exhaust emissions, improving sealing, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

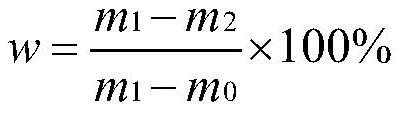

Method used

Image

Examples

Embodiment 1

[0021] The cleaning agent of the automobile three-way catalytic converter, the cleaning agent comprises the raw materials of following weight parts: 10 parts of sulfosalicylic acid, 10 parts of composite surfactant, 1 part of builder, 1 part of composite corrosion inhibitor, nitrilo trisodium 0.5 parts of sodium acetate, 60 parts of deionized water.

[0022] The composite surfactant is prepared by mixing coconut oil fatty acid diethanolamide, sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether with a molar ratio of 1:1:2.

[0023] The composite corrosion inhibitor is prepared by mixing triethanolamine, sodium silicate, sodium tetraborate and sodium benzoate with a mass ratio of 3:6:6:2.

[0024] The builder is prepared by mixing sodium silicate and sodium carbonate at a molar ratio of 1:1.

[0025] Put the three-way catalytic converter and cleaning agent in a shaking table with a volume ratio of 3:1 and shake and wash. Set the cleaning temperature at 24°C and...

Embodiment 2

[0027] The cleaning agent of automobile three-way catalytic converter, cleaning agent comprises the raw material of following weight portion: 20 parts of sulfosalicylic acid, 15 parts of composite surfactants, 5 parts of builders, 5 parts of composite corrosion inhibitors, nitrilo trisodium 1 part of sodium acetate, 90 parts of deionized water.

[0028] The composite surfactant is prepared by mixing coconut oil fatty acid diethanolamide, sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether with a molar ratio of 1:1:3.

[0029] The composite corrosion inhibitor is prepared by mixing triethanolamine, sodium silicate, sodium tetraborate and sodium benzoate with a mass ratio of 3:8:6:2.

[0030] The builder is prepared by mixing sodium silicate and sodium carbonate at a molar ratio of 1:1.

[0031] Put the three-way catalytic converter and cleaning agent in a shaking table at a volume ratio of 3:1 and shake and wash. Set the cleaning temperature at 35°C and rotate...

Embodiment 3

[0033] The cleaning agent of automobile three-way catalytic converter, cleaning agent comprises the raw material of following weight portion: 12 parts of sulfosalicylic acid, 11 parts of composite surfactant, 2 parts of builder, 2 parts of composite corrosion inhibitor, nitrilo trisodium 0.6 parts of sodium acetate, 70 parts of deionized water

[0034] The composite surfactant is prepared by mixing coconut oil fatty acid diethanolamide, sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether with a molar ratio of 1:1:2.

[0035] The composite corrosion inhibitor is prepared by mixing triethanolamine, sodium silicate, sodium tetraborate and sodium benzoate with a mass ratio of 3:6:6:2.

[0036] The builder is prepared by mixing sodium silicate and sodium carbonate at a molar ratio of 1:1.

[0037] Put the three-way catalytic converter and cleaning agent in a shaking table with a volume ratio of 3:1 and shake and wash. Set the cleaning temperature at 24°C and rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com