Binary composite cob core cigarette filter as well as preparation method and application thereof

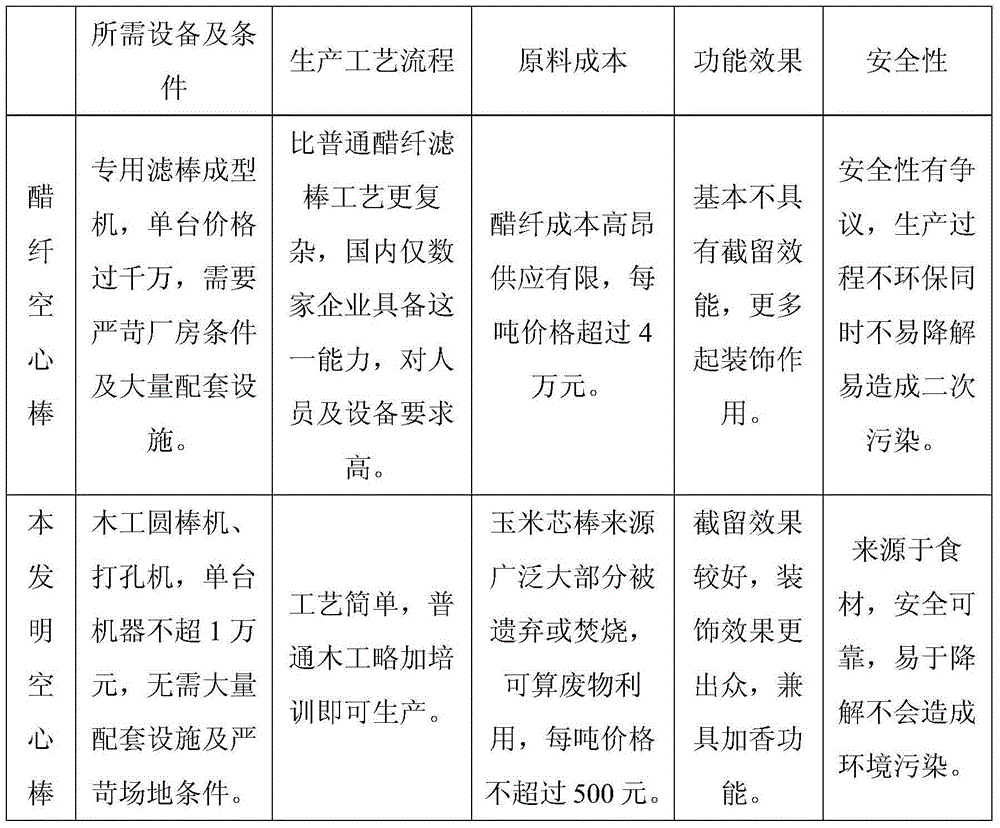

A corncob cob, binary composite technology, applied in the application, tobacco, smoke oil filter and other directions, can solve problems such as restricting the industrial application of filter rods, and achieve the effect of realizing industrialized mass production, suitable hardness, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The 3.0 / 32000 acetate fiber tow is prepared into a solid filter rod with a circumference of 23.5mm and a length of 120mm according to the steps of opening, gluing, and forming; It is processed and polished into a cylinder with a circumference of 23.5 mm and a length of 120 mm on a woodworking round rod machine, and then a hollow filter rod section is obtained by punching a through hole with a diameter of 3 mm in the axis of the cylinder with a wood puncher; The solid filter rod section and the hollow filter rod section are compounded on the mouth rod compounding machine according to the length ratio of 15:10 to prepare a binary composite filter, and trial-produce cigarettes. The hollow core section of the prepared cigarette is in contact with shredded tobacco, and its appearance is similar to that of ordinary cigarettes. No difference. A cellulose acetate hollow core composite filter rod of the same specification was prepared simultaneously as a control. The results of...

Embodiment 2

[0027] The 3.0 / 32000 acetate fiber tow is prepared into a solid filter rod with a circumference of 23.5 mm and a length of 108 mm according to the steps of opening, gluing and forming; the preparation method of the hollow filter rod is as follows: remove impurities from the naturally sun-dried corn cobs, Process it into a cylinder with a circumference of 23.5 mm and a length of 84 mm on a lathe, and then use a puncher to punch a through hole with a diameter of 5 mm in the axis of the cylinder to obtain a hollow filter rod segment; the solid filter rod The segment and the hollow filter rod segment are compounded on a mouth rod compounding machine according to the length ratio of 18:7 to obtain a binary composite rod, and a trial cigarette is produced. The hollow core segment of the prepared cigarette is close to the lip end, and its appearance is very different from that of ordinary cigarettes, making it unforgettable. A cellulose acetate hollow core composite filter rod of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com