Apparatus and method for removing ammonia in ammoxidation gas

An ammonia oxidation reaction and reaction gas technology, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems of shortened operation cycle, organic polymer polymerization loss, increased device consumption, etc., to achieve uniform gas-liquid contact, improve Cooling effect, effect of reducing polymerization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

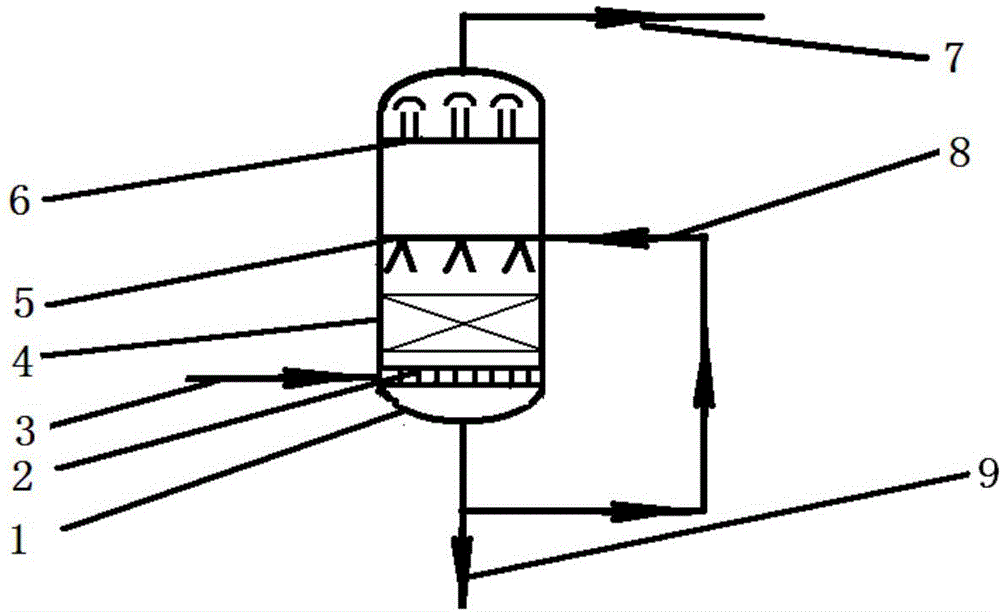

[0029] Adopt the removal equipment of ammonia in the ammoxidation reaction gas of the present invention, set 2 layers in the removal equipment and form by the reaction gas neutralization liquid spray layer that hollow cone shower head is arranged in square, the arrangement density of shower head is 2 Nozzle / m 2, the distance between the last spray layer is 1.2 of the distance between the next spray layer, and above the spray layer, 2 bubble cap plates with theoretical plates are set as demisters, and the reaction gas neutralizes the liquid spray layer 6 pieces of theoretical plate grid packing are arranged below and above the inlet of the reaction gas, and a dendritic porous distributor is installed at the inlet of the reaction gas. The removal rate of ammonia in the reaction gas reaches 99.9% after being neutralized by the spray layer of the nozzle of the removal equipment, effectively The ammonia in the reaction gas is effectively removed, the polymerization loss of organic ...

Embodiment 2

[0031] The neutralization device includes a shell, a reaction gas inlet and a reaction gas outlet, a reaction gas neutralization liquid inlet and a reaction gas neutralization liquid outlet, the reaction gas inlet is set at the lower part of the ammonia neutralization device, and the reaction gas outlet is set at the top of the ammonia neutralization device , the inlet of the reaction gas neutralizing liquid is set above the inlet of the reaction gas, and the outlet of the neutralizing liquid is set at the bottom of the ammonia neutralization device, wherein trays or packing are arranged below the inlet of the reaction gas neutralizing liquid and above the inlet of the reaction gas in the ammonia neutralization device , and the inlet of the neutralizing liquid is provided with a liquid distributor.

[0032] Each spray layer is provided with a main pipe, a branch pipe and a short pipe. The branch pipe is arranged on the main pipe, and the short pipe is arranged on the branch pip...

Embodiment 3

[0036] The spray equipment for neutralization reaction includes a shell, a reaction gas inlet and a reaction gas outlet, a neutralization liquid inlet and a neutralization liquid outlet, the reaction gas inlet is set at the lower part of the spray equipment, and the reaction gas outlet is set at the bottom of the spray equipment At the top, the neutralizing liquid inlet is set above the reaction gas inlet, and the neutralizing liquid outlet is set at the bottom of the spray equipment, wherein the neutralizing liquid inlet is set up with a spray layer composed of nozzles arranged in geometric shapes, and each layer of spraying The main pipe, branch pipe and short pipe are arranged on the layer, the branch pipe is arranged on the main pipe, and the short pipe is arranged on the branch pipe, wherein the diameter of the branch pipe is 0.5 times the diameter of the main pipe, and the diameter of the short pipe is 0.7 times the diameter of the branch pipe.

[0037] The number of theo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com