Magnetostatic method for online monitoring vibration marks of magneto-conductive continuous casting billet

A continuous casting slab and magnetic force technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve the problems of complex, limited and difficult ray equipment, and achieve simple detection equipment, simple measurement process, Detect fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

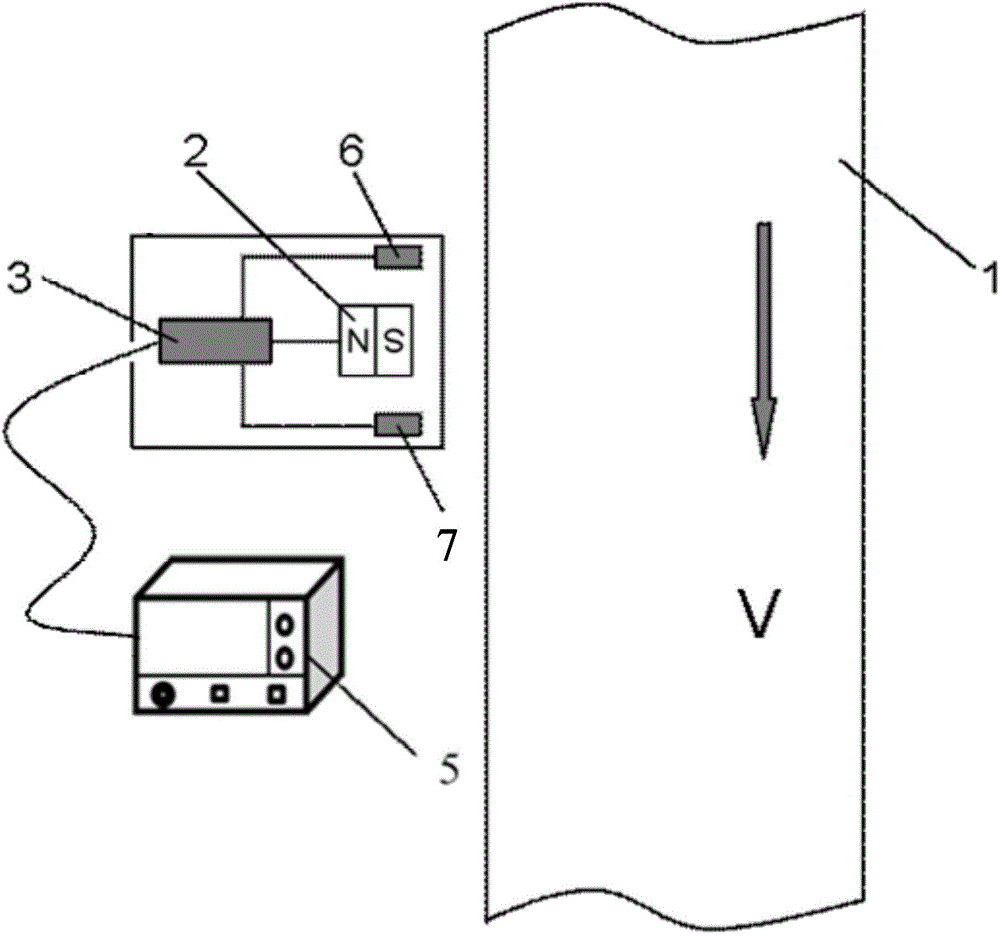

[0028] figure 1 It is a schematic diagram of the system used in the static magnetostatic method for on-line monitoring of vibration marks of magnetically conductive continuous casting slabs in the present invention, as shown in the figure, which includes a continuous casting slab 1 to be tested that has been pulled down after being water-cooled. Place the permanent magnet 2 on the surface of the continuous casting slab 1 to be tested, and the load cell 3 connected with the permanent magnet and the oscilloscope 5 connected on the load cell 3, and the thermocouple 6 and the thermocouple for measuring the surface temperature of the slab A distance measuring sensor 7 for measuring the distance between the permanent magnet and the surface of the slab.

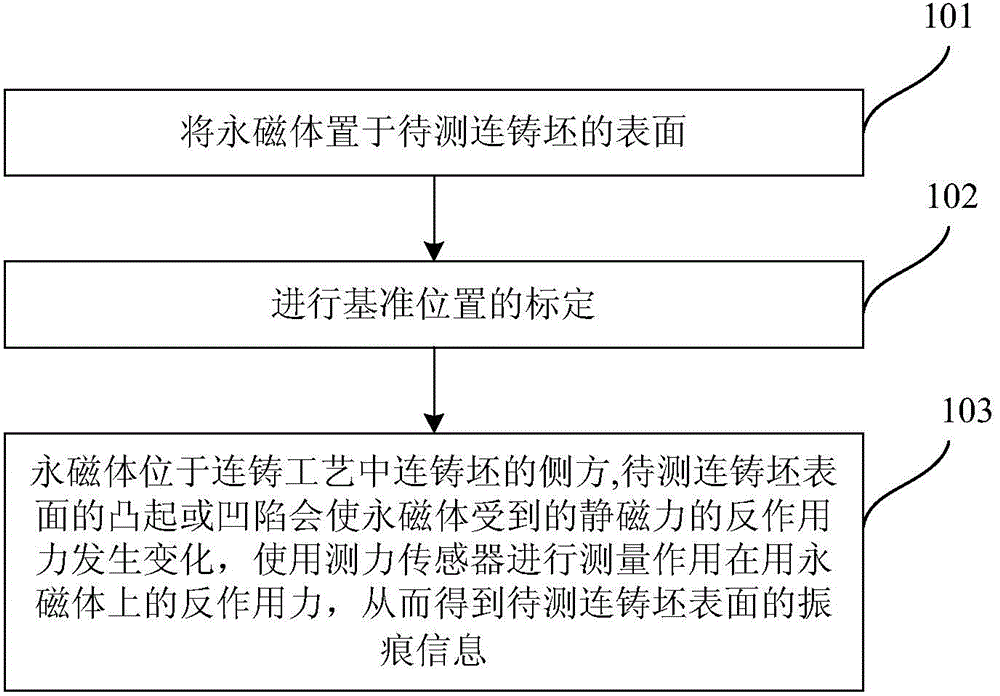

[0029] figure 2 It is a flow chart of the static magnetic force meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com