Treatment method of MOCVD reactor

A processing method and reactor technology, which are used in gaseous chemical plating, metal material coating process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

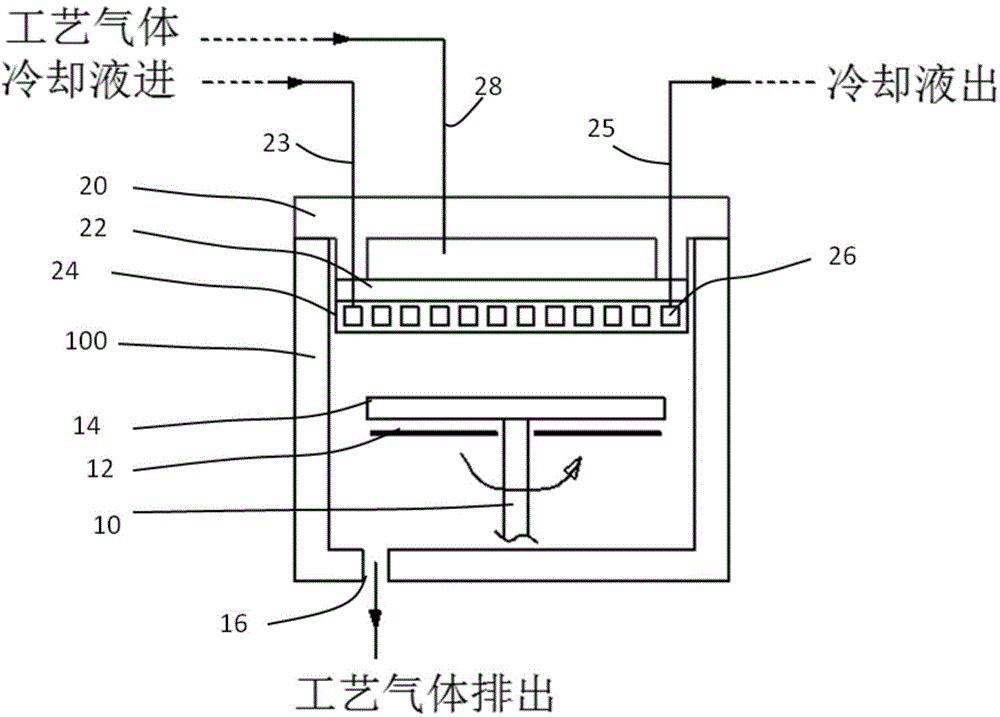

[0009] The invention solves the problem of the iron in the gas circulation pipeline of the MOCVD reactor polluting the epitaxial growth wafer. During the crystal growth process, the heater 12 needs to heat the wafer tray 14 on which wafers to be processed are placed. At the same time, the cooling liquid pipeline in the spray head above passes into the cooling liquid with a suitable temperature to make the temperature of the cooling plate 24 stable at 50 degrees Celsius. The sealing mechanism between the gas pipes of the shower head is damaged, resulting in gas leakage. Metal-organic gas sources flow through the liquid metal-organic compound container through a carrier gas such as nitrogen, and then bring out metal-organic compound molecules. These molecules brought out by the carrier gas will be saturated with different temperatures during the flow in the pipeline. The precipitation becomes liquid and precipitates again. In order to prevent these molecules from precipitation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com