Substrate Forming Method

A molding method and substrate technology, applied in the direction of structural parts, battery pack parts, manufacturing tools, etc., can solve the problems of increasing the cost of tab cutting and molding, slow cutting speed, and easy wear of the knife mold, so as to improve the cutting quality, Increased cutting speed and improved molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The substrate molding method according to the present invention will be described in detail below with reference to the accompanying drawings.

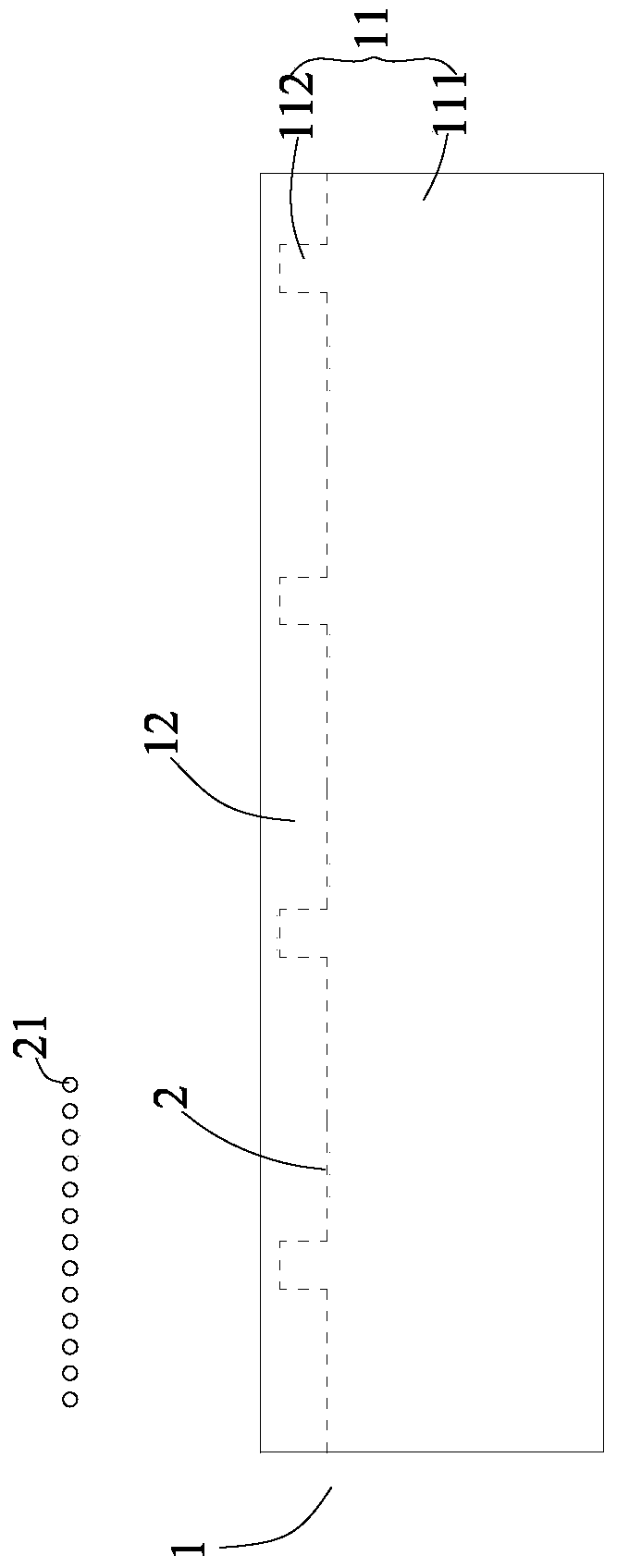

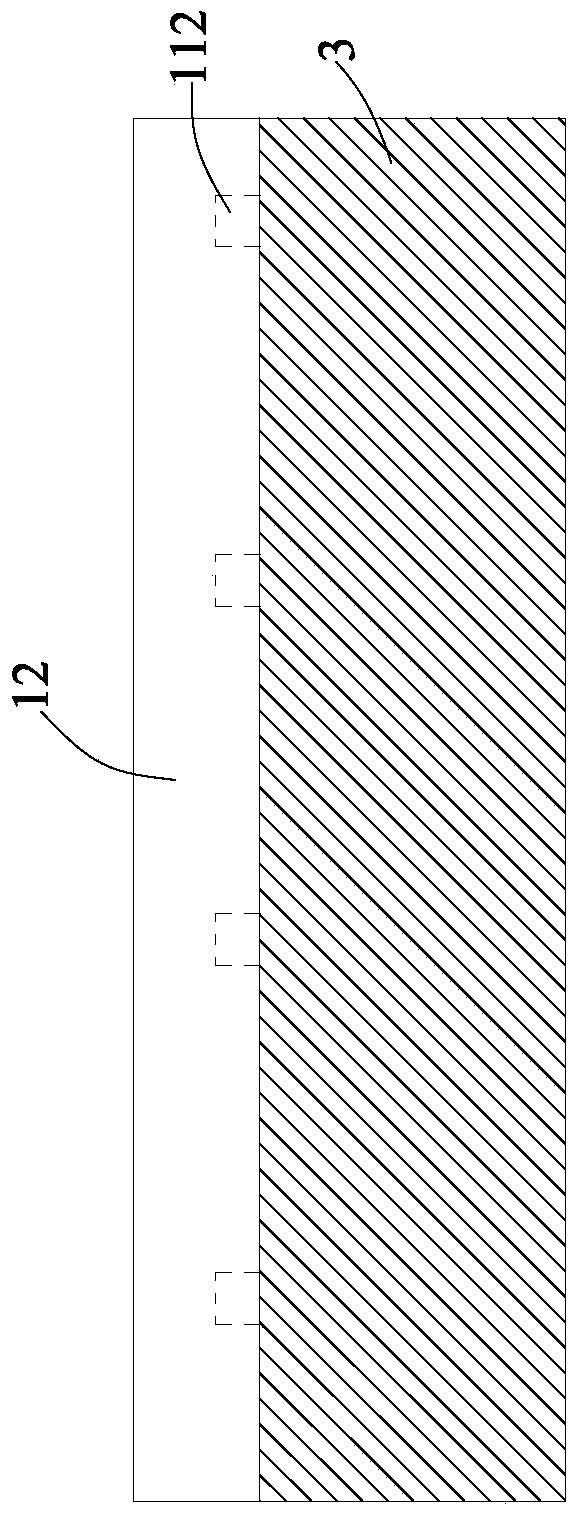

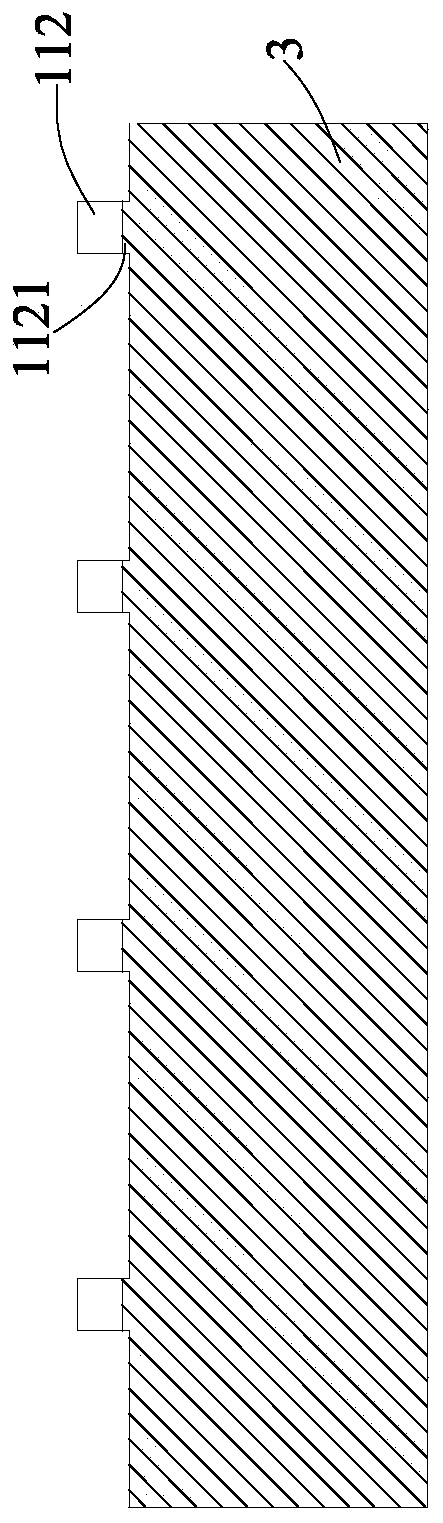

[0022] refer to Figure 1 to Figure 3 According to the substrate forming method of the present invention, the method includes steps: Step 1: During the conveyance of the substrate 1 after unwinding, use a laser to pre-cut the substrate 1 along the pre-cutting track, and the substrate 1 after the pre-cut is not cut. Cut off completely by laser and form pre-cutting slit 2 along pre-cutting track on base material 1, the base material 1 after the pre-cut forms the part 11 that is positioned at pre-cut slit 2 both sides and scrap part 12 (refer to figure 1 ); Step 2: in the conveying process of the base material 1 after pre-cutting, on at least one surface of the base material 1 (single side or both sides of the base material 1), the molding part formed after the base material 1 is pre-cut The side where 11 is located is coated wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com