Metal plate UV roller coating drying system

A drying system and metal plate technology, applied in coatings, devices for applying liquid to surfaces, paint spray booths, etc., can solve problems such as inability to treat exhaust gas, environmental pollution, etc., to remove harmful gases, prevent environmental pollution, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

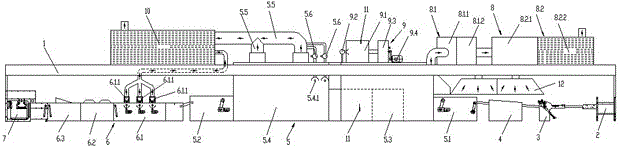

[0011] Embodiment 1: A metal plate UV roller coating drying system, comprising a long direction sealed housing 1, inside the housing 1 are arranged sequentially connected feeder 2, coating machine 3, conveying section 4, Drying room 5, UV light curing device 6 and blanking machine 7, drying room 5 includes feed section 5.1 and discharge section 5.2 at both ends, drying room heating chamber 5.3, drying room cooling chamber 5.4, UV light curing device 6 includes light Solid section 6.1, cooling section 6.2, and sample-seeing delivery section 6.3. Two conical smoke collection hoods 12 are arranged side by side above the delivery section 4. The smoke collection hoods 12 are connected to the waste gas treatment device 8 arranged on the top of the housing 1 through pipelines. The exhaust gas treatment device 8 includes a gas collection chamber 8.1 and a filter chamber 8.2 connected to the gas collection chamber 8.1. An intermediate partition is arranged in the gas collection chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com