Method for improving integrity of cutting surface of aluminum-lithium alloy workpiece

A technology of cutting surface, aluminum-lithium alloy, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of non-conformity, high waste liquid treatment cost, large plant area, etc., to reduce processing costs, control Pollution, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The illustrated embodiments are not intended to be exhaustive of all embodiments in accordance with the invention. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention.

[0023] The cutting system experimental device used in the embodiment of the present invention selects a polycrystalline diamond face milling cutter as a processing tool, and the tool is clamped on a MikronUCP800 five-axis machine tool. The specific steps are:

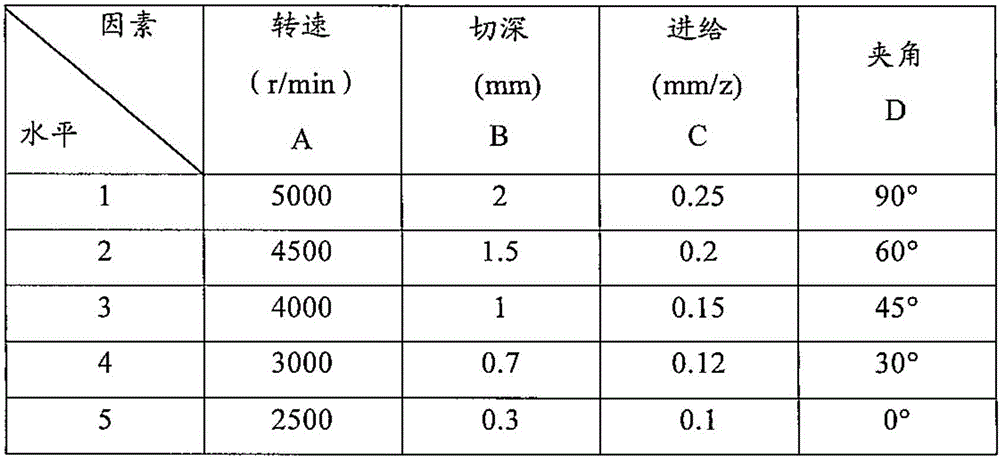

[0024] 1. The geometric parameters of the tool are found to be: shank diameter 100mm; radial rake angle 10°, axial rake angle 5°, and the tool material is polycrystalline diamond (PCD). Select the range of process parameters as shown in Table 1 from level V to level I.

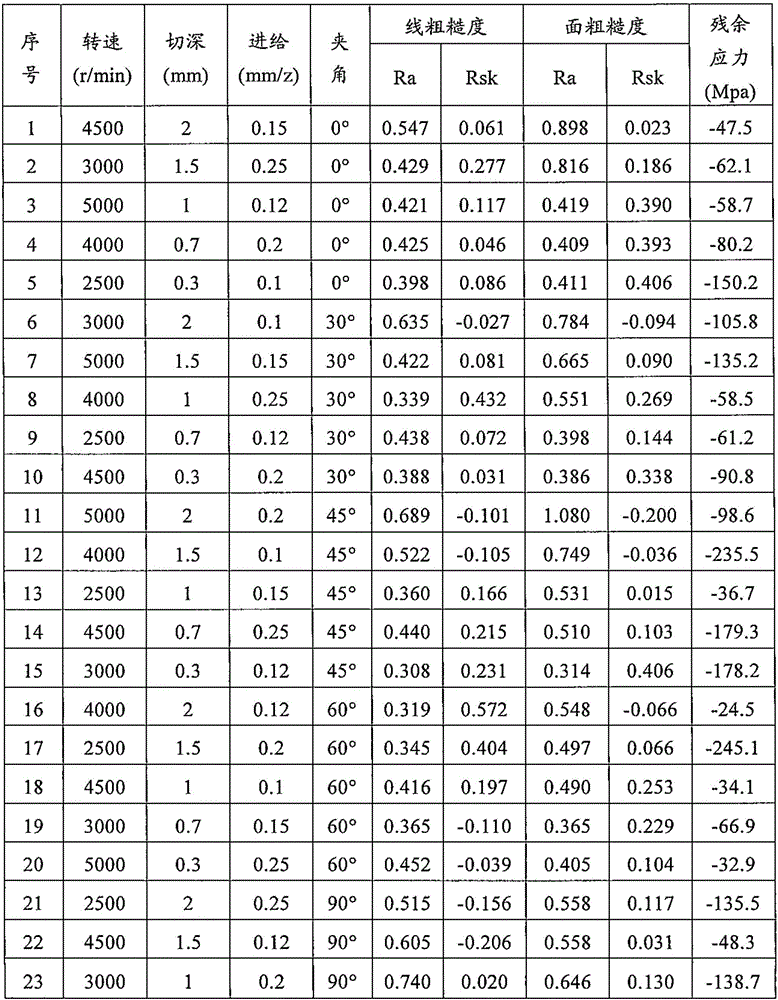

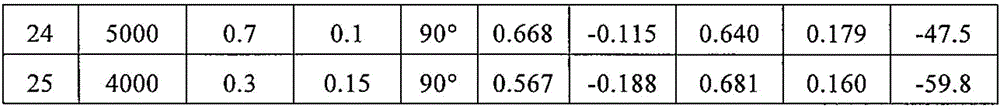

[0025] 2. Orthogonal experimental design with five levels and four factors was adopted. Take speed, depth of cut, feed, angle between feed direction and rolling di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com