Exhaust device of plastic thin film extruder

A technology of plastic film and exhaust device, which is applied in the field of machinery, can solve problems such as difficulty in device assembly, and achieve the effects of improving assembly convenience, stability, and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

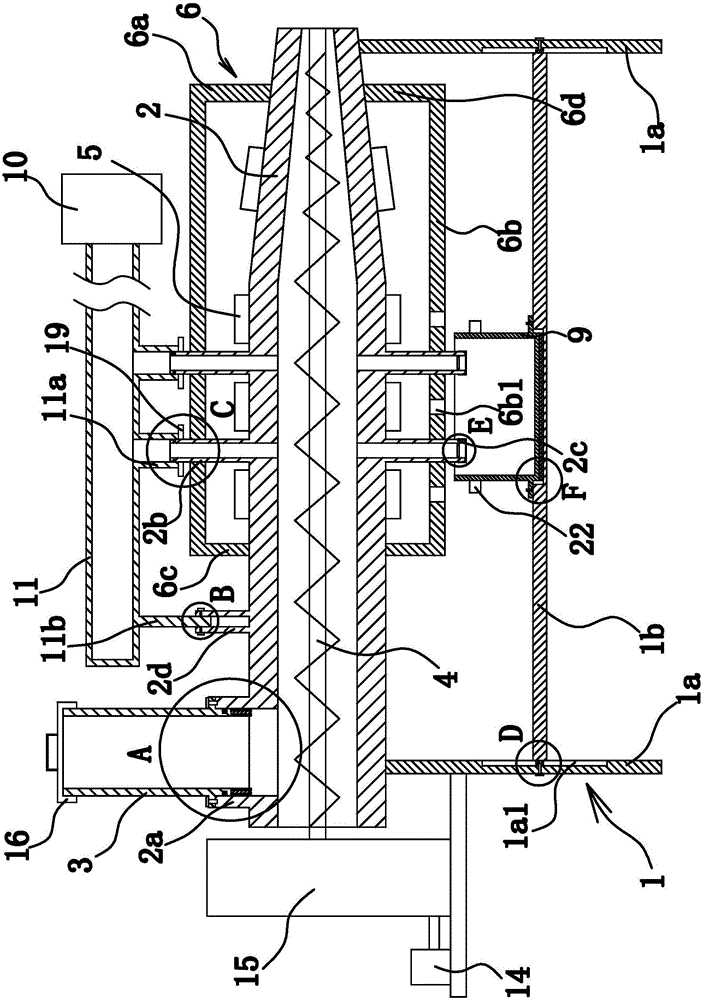

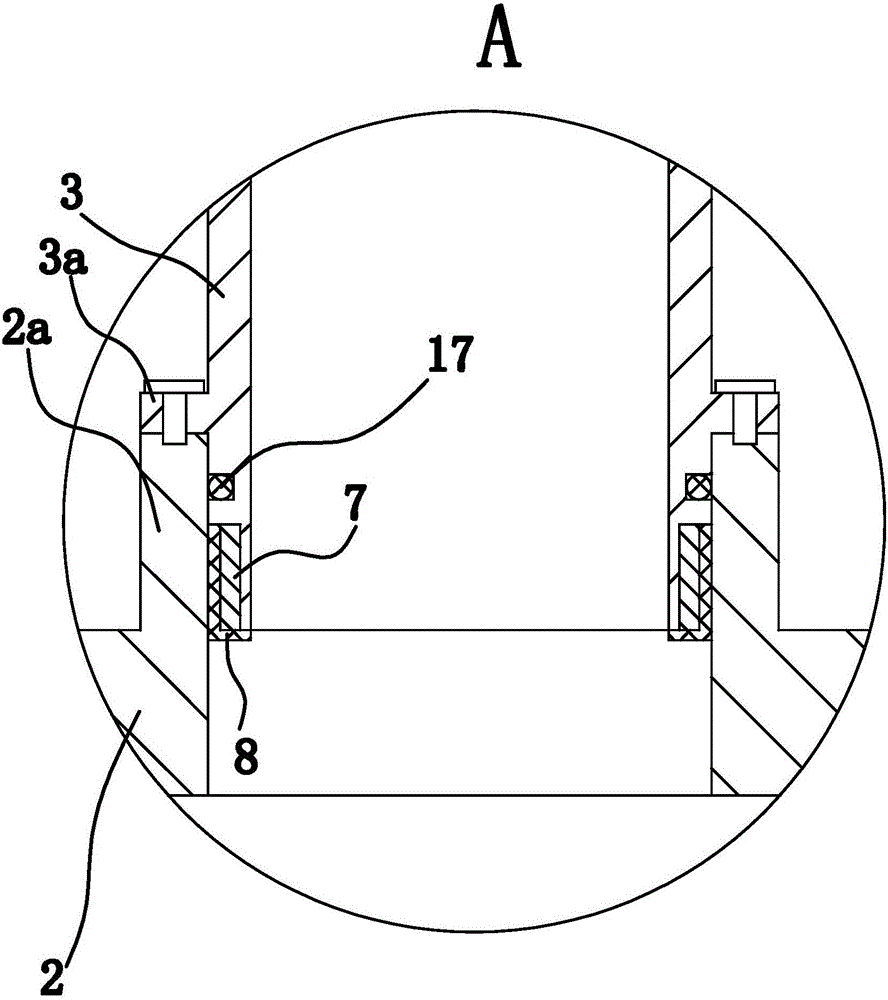

[0031] Such as Figure 1 to Figure 8 As shown, the plastic film extrusion device consists of a frame 1, an extrusion cylinder 2, a feeding cylinder 3, a feeding screw 4, an electric heater 5, a heat insulation cylinder 6, a magnetic block 7, a protective cover 8, a water storage tank 9, a pump Air pump 10, exhaust pipe 11, dustproof net 12, pressure cap 13 etc. are formed. Wherein, the heat insulation cylinder 6 and the protective cover 8 are all made of thermal insulation materials, such as thermal insulation rock wool, molded polystyrene board, extruded polystyrene board, etc.; the feeding cylinder 3 and the water storage tank 9 are made of magnetic Material, the magnetic material can be iron or iron alloy.

[0032] Specifically, as figure 1 and Figure 5 As shown, the frame 1 is I-shaped, and the frame 1 includes two connecting plates 1a arranged vertically and a supporting plate 1b between the two connecting plates 1a. Wherein, the two ends of the support plate 1b are ...

Embodiment 2

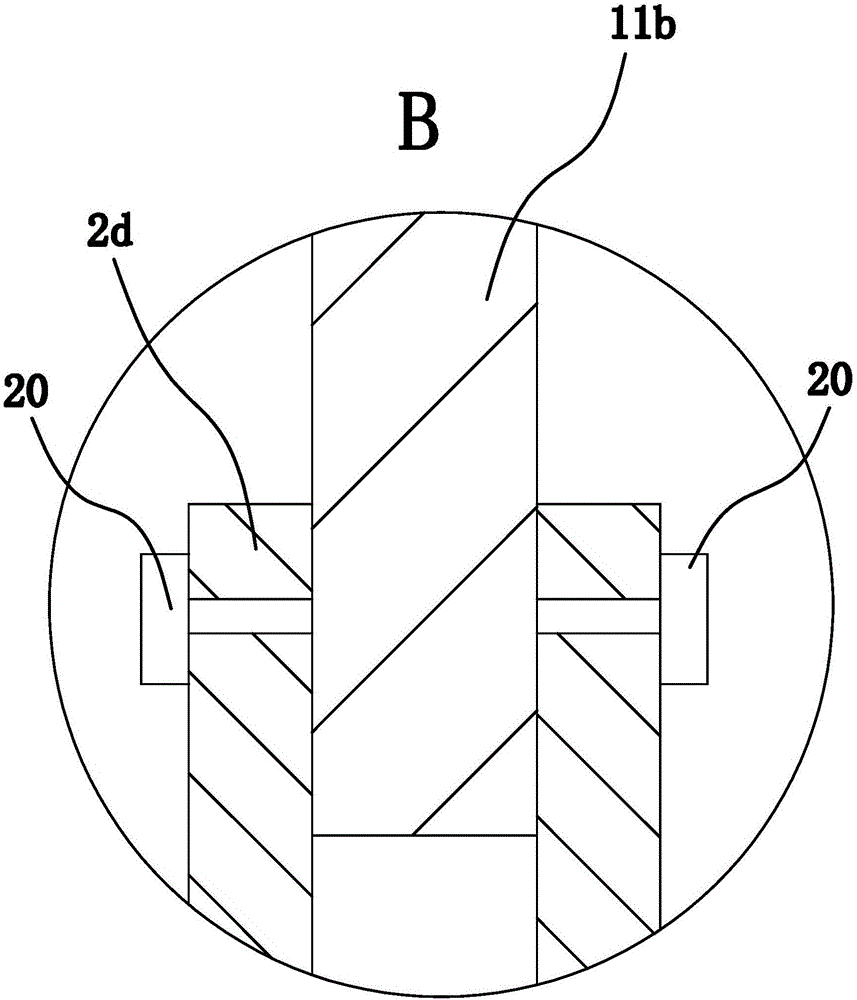

[0048] The structure and principle of the second embodiment are basically the same as those of the first embodiment, except that the locking mechanism includes the second threaded hole penetrating through the side wall of the positioning part 2d, the third threaded hole provided on the side wall of the sliding part 11b and There are several bolts 2 and 3 threaded in the threaded hole 2 and they are distributed along the axial direction of the sliding part 11 b . The end of the bolt 2 is threaded in one of the threaded holes 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com