Intelligent laser 3D printing device and method

A 3D printing and laser technology, applied in the direction of improving energy efficiency, process efficiency, additive processing, etc., can solve problems such as parts deformation and cracking, internal defects, internal organization, etc., to improve quality, reduce operating costs, and improve intelligence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

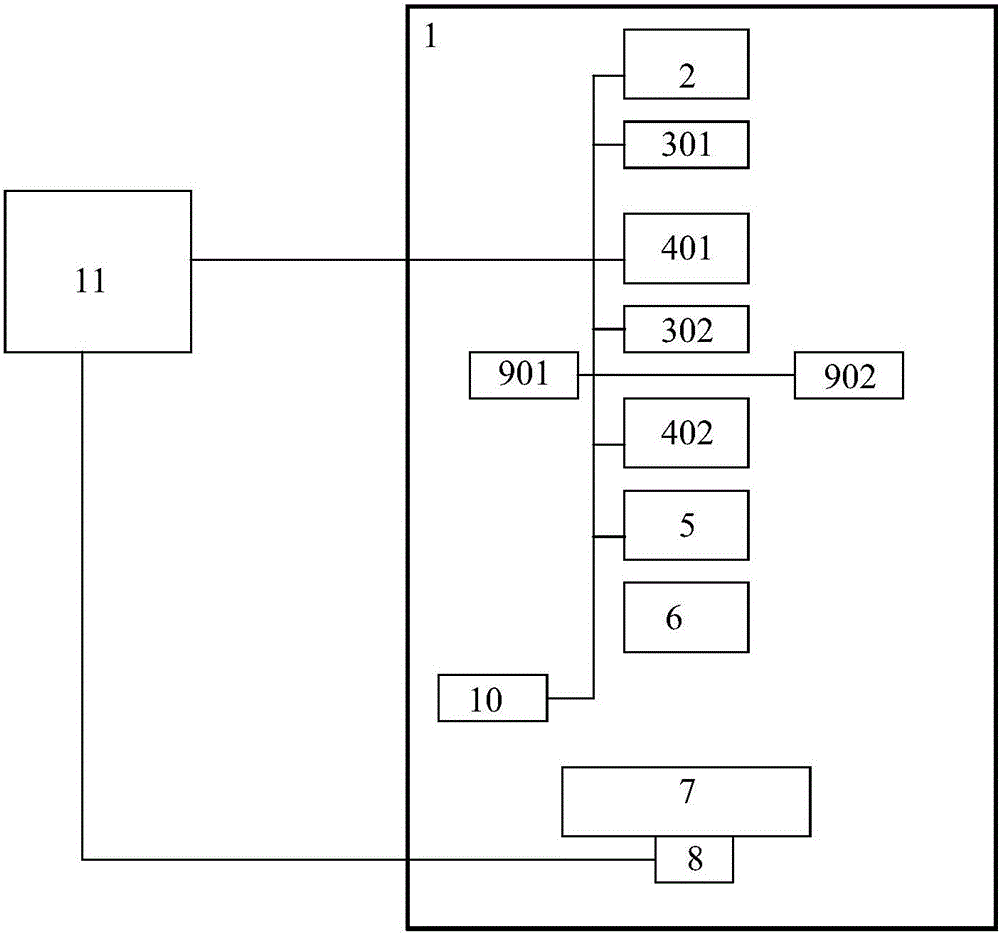

[0032] The present invention proposes an intelligent laser 3D printing device and printing method, such as figure 1 As shown, the printing device includes a housing 1, a semiconductor laser 2, a vibrating mirror X301, a vibrating mirror Y302, a scanning mirror X401, a scanning mirror Y402, a field mirror 5, a melting pool 6, a workpiece table 7, a drive motor 8, CCDA901, CCDB902, laser heterodyne interferometer 10 and computer 11. The workpiece table 7 and the drive motor 8 form a six-axis parallel load system, and the drive motor 8 drives the workpiece table 7 to move, so as to realize the azimuth movement control of the physical objects on the workpiece table 7 . Described semiconductor laser device 2, vibrating mirror X301, vibrating mirror Y302, scanning mirror X401, scanning mirror Y402, field mirror 5, melting pool 6, work table 7, drive motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com