Dye wastewater treatment technology

A technology of dye wastewater and treatment process, which is applied in textile industry wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc. It can solve problems such as poor treatment effect, secondary pollution, and difficult treatment, and achieve cost reduction. Low cost, high output, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

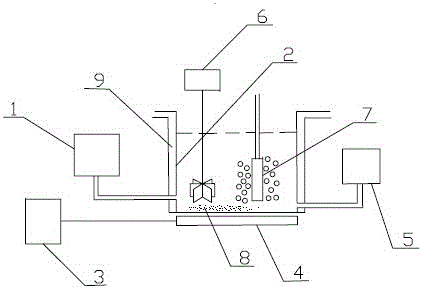

Image

Examples

Embodiment 1

[0032] A dye wastewater treatment process is as follows: in the wastewater storage tank to be treated, the initial concentration of the wastewater to be treated is adjusted to 489 mg / L, and the pH value is adjusted to 5.0; Add 5.0 g / L of Fe-Ni-Mn / Al to the wastewater 2 o 3 Heterogeneous catalyst and 5 mL / L of H 2 o 2 , turn on the ultrasonic generator and transducer, wherein the output power and frequency of the ultrasonic generator are 200W and 20 kHz respectively; and the dye wastewater is filled with Ar + air saturated gas through the aeration head, and the two are in volume ratio 1:1 mix. Through intensified low-frequency ultrasonic degradation for 3 h; the treated wastewater was put into the treated wastewater storage tank. After testing, the chroma removal rate of the treated wastewater is 95.5%.

Embodiment 2

[0034] A dye wastewater treatment process is as follows: in the wastewater storage tank to be treated, the initial concentration of the wastewater to be treated is adjusted to 495 mg / L, and the pH value is adjusted to 3.0; Add 8.0 g / L of Fe-Ni-Mn / Al to the wastewater 2 o 3 Heterogeneous catalyst and 5mL / L of H 2 o 2, turn on the ultrasonic generator and transducer, wherein the output power and frequency of the ultrasonic generator are 300W and 40 kHz respectively; and fill the dye wastewater with Ar and air saturated gas through the aeration head, and the two are proportional to the volume ratio 1:1 mix. Through intensified low-frequency ultrasonic degradation for 2 h; the treated wastewater was put into the treated wastewater storage tank. After testing, the chroma removal rate of the treated wastewater was 98.2%.

Embodiment 3

[0036] A dye wastewater treatment process is as follows: in the wastewater storage tank to be treated, the wastewater initial concentration of the wastewater to be treated is adjusted to 481mg / L, and the pH value is adjusted to 4.3; then the wastewater is put into the wastewater treatment working pool, and the wastewater were added to

[0037] 6.0 g / L Fe-Ni-Mn / Al 2 o 3 Heterogeneous catalyst and 5mL / L of H 2 o 2 , turn on the ultrasonic generator and transducer, wherein the output power and frequency of the ultrasonic generator are 250W and 30 kHz respectively; and the dye wastewater is filled with Ar + air saturated gas through the aeration head, and the two are in volume ratio 1:1 mix. Through intensified low-frequency ultrasonic degradation for 2 h; the treated wastewater was put into the treated wastewater storage tank. After testing, the chroma removal rate of the treated wastewater is 97%.

[0038] A dye wastewater treatment process of the present invention uses l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com