Method for industrial scale preparation of 4-vinylpyridine

A vinylpyridine, industrial-scale technology, applied in the field of industrial-scale preparation of 4-vinylpyridine, can solve the problems of high requirements, high reaction temperature, and high unit consumption, meets general equipment requirements, simple production process, and no danger. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

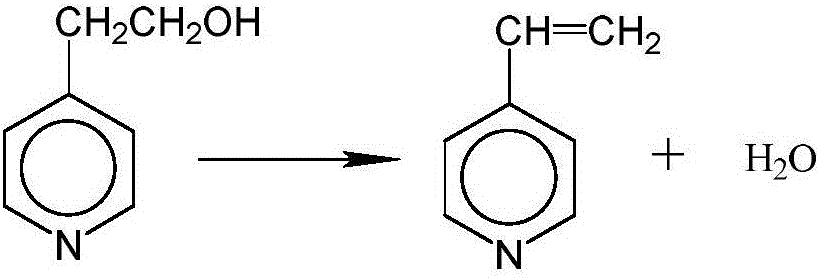

Image

Examples

Embodiment 1

[0022] The weight ratio of 4-hydroxyethylpyridine to catalyst calcium chloride is 1:1.

[0023] Feeding amount:

[0024] 4-Hydroxyethylpyridine (content 98.57%) 1247.84kg, converted to pure 1230kg;

[0025] Calcium chloride (content 94%) 1031.58kg, converted to pure 970kg;

[0026] Put the catalyst into the reaction kettle, under stirring, gradually heat up to 180°C, and time the reaction, gradually add 4-hydroxyethylpyridine dropwise, and at the same time, vacuumize the reaction kettle, and the reaction solution will undergo dehydration reaction immediately, and the reaction product (reaction generated 4-vinylpyridine and water) are distilled from the steam outlet, reacted at 185±5°C for 5 minutes, collected fractions with a boiling range of 60-100°C / 10-150 mmHg, and separated the reaction water contained in the fractions by alkali analysis , the reaction generates water and dissolves solid sodium hydroxide or sodium chloride for alkali analysis, and the lower layer is NaOH...

Embodiment 2

[0029] The weight ratio of 4-hydroxyethylpyridine to catalyst magnesium chloride is 1:1.

[0030] Feeding amount:

[0031] 4-Hydroxyethylpyridine (content 98.57%) 1247.84kg, converted to pure 1230kg;

[0032] Magnesium chloride (content 46%) 1031.58kg, converted to pure 475kg;

[0033] The reaction temperature is 185±5°C, and the reaction time is 30 minutes;

[0034] Obtain finished product 900.55kg, content 98.28%, convert pure 885.06kg, yield 84.29%; Moisture 0.48%, all the other are with embodiment 1.

Embodiment 3

[0036] The weight ratio of 4-hydroxyethylpyridine to catalyst sodium acetate is 1:1.

[0037] Feeding amount:

[0038] 4-Hydroxyethylpyridine (content 98.57%) 1247.84kg, converted to pure 1230kg;

[0039] Sodium acetate (content 98%) 421.05kg, converted to pure 413kg;

[0040] Reaction temperature 185±5℃, reaction time 10min;

[0041] Obtain finished product 920.85kg, content 98.58%, convert pure 907.77kg, yield 86.46%; Moisture content 0.51%, all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Origami | aaaaa | aaaaa |

| Origami | aaaaa | aaaaa |

| Origami | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com