Composite for making floor lamp panel and preparing method of composite

A composite material and panel technology, which is applied in the field of composite materials and its preparation for making floor lamp panels, can solve problems such as easy to be scalded and high surface temperature of floor lamp panels, achieve good reflection of sunlight, reduce surface energy, and have a dense and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

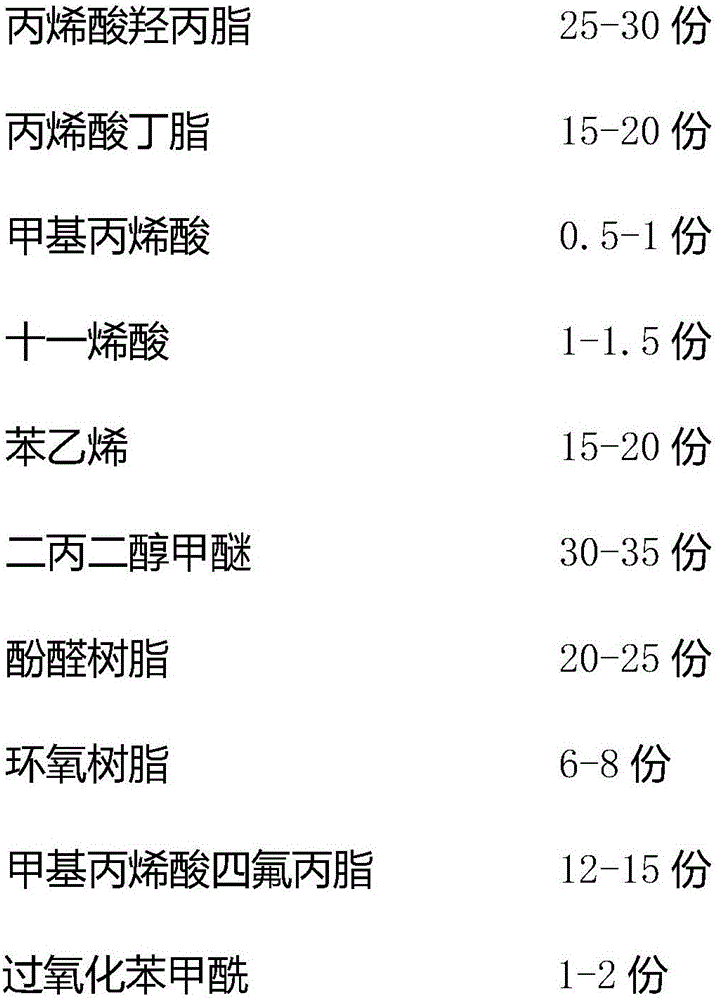

[0017] Take the following raw materials:

[0018]

[0019] To make the floor lamp panel:

[0020] Add hydroxypropyl acrylate, methacrylic acid, styrene, epoxy resin, and dipropylene glycol methyl ether into the mixer, stir at a speed of 80 rpm, and at the same time heat the mixture to 80°C for 15 minutes; add butyl acrylate, Undecylenic acid was added and continued to stir, the temperature was lowered to 75°C, and maintained for 25 minutes; tetrafluoropropyl methacrylate was added, and the temperature was maintained at 70°C for 2 hours after stirring fully; Benzoyl peroxide was added to the mixture, fully After stirring, keep the temperature at 70°C and let it stand for 2.5 hours to react; cool to room temperature and discharge to obtain the target product; make the target product into a 2cm thick plate for later use.

Embodiment 2

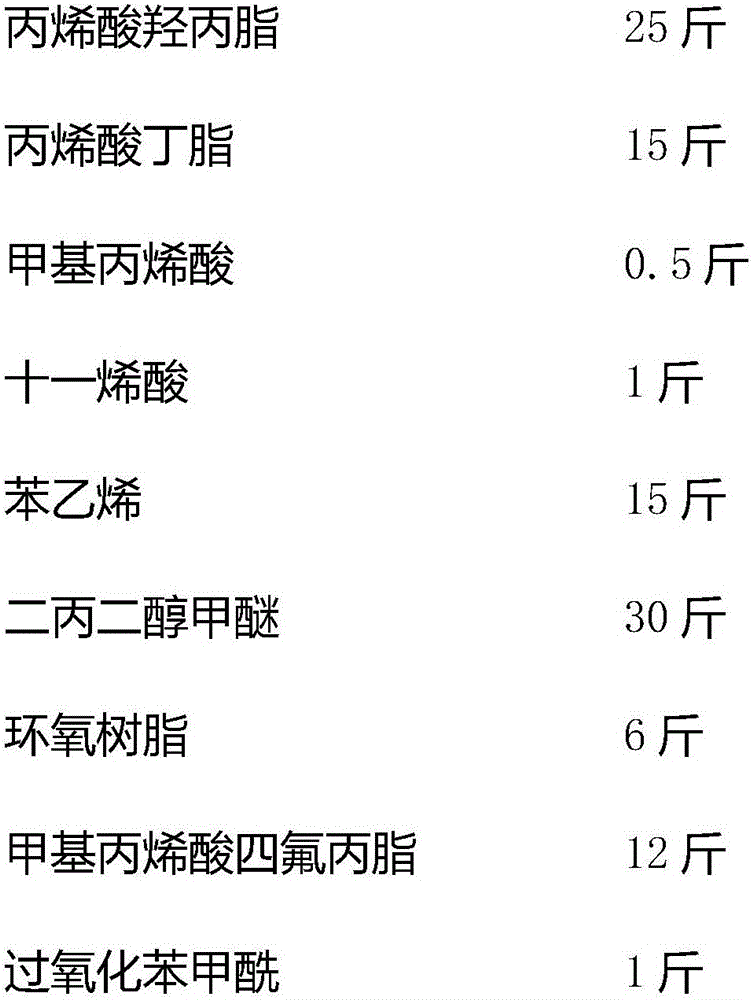

[0022] Take the following raw materials:

[0023]

[0024] To make the floor lamp panel:

[0025] Add hydroxypropyl acrylate, methacrylic acid, styrene, epoxy resin, and dipropylene glycol methyl ether into the mixer, stir at a speed of 90 rpm, and at the same time heat the mixture to 85°C for 20 minutes; add butyl acrylate, Add undecylenic acid and continue stirring, lower the temperature to 80°C and keep it for 30 minutes; add tetrafluoropropyl methacrylate, stir well and keep it at 75°C for 2.5 hours; add benzoyl peroxide to the mixture, fully After stirring, keep the temperature at 75°C and let it stand for 3 hours to react; cool to room temperature and discharge to obtain the target product; make the target product into a 2cm thick plate for later use.

Embodiment 3

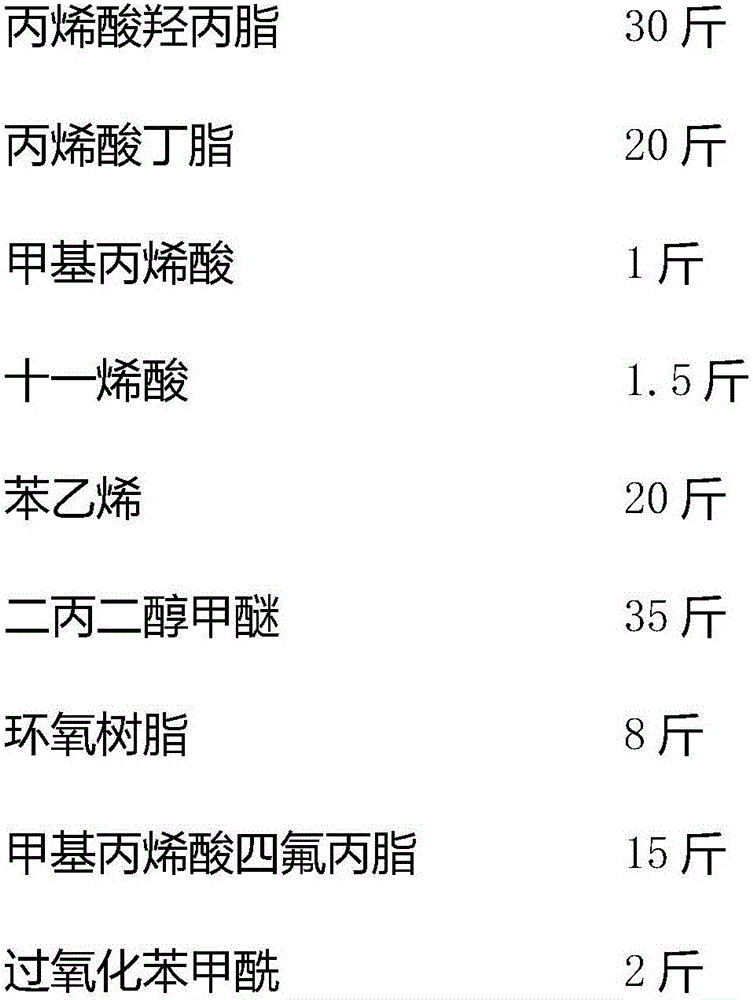

[0027] Take the following raw materials:

[0028]

[0029] To make the floor lamp panel:

[0030] Add hydroxypropyl acrylate, methacrylic acid, styrene, epoxy resin, and dipropylene glycol methyl ether into the mixer, stir at a speed of 85 rpm, and heat the mixture to 82°C for 18 minutes; add butyl acrylate, Undecylenic acid was added and continued to stir, the temperature was lowered to 78°C, and maintained for 27 minutes; tetrafluoropropyl methacrylate was added, and the temperature was maintained at 73°C after stirring thoroughly for 2.2 hours; benzoyl peroxide was added to the mixture, fully After stirring, keep the temperature at 73°C and let it stand still for 2.7 hours; cool to room temperature and discharge to obtain the target product; make the target product into a 2cm thick plate for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com