Synthetic method of kapton polyimide in ionic liquid

A technology of ionic liquid and polyimide, which is applied in the field of polyimide synthesis, can solve problems such as harsh reaction conditions and complex synthesis operations, and achieve increased speed and yield, cheap and easy-to-obtain raw materials, and a clean and safe preparation environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

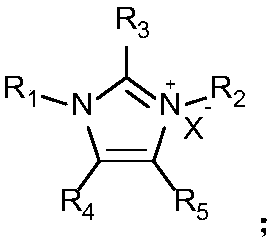

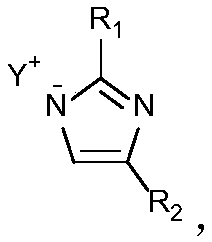

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 218.12 mg of pyromellitic dianhydride and 200.24 mg of 4,4'-oxybenzidine diamine in 5.0 mL of 1-ethyl-3-methylimidazolium acetate ionic liquid; under stirring conditions, gradually heat to 80 degrees Celsius; after 8 hours of reaction, the precipitated solid was separated by filtration; the obtained solid was washed once with water, three times with methanol, and dried to obtain the product Kapton polyimide with a yield of 92%, an average molecular weight of 34.1kDa, and a molecular weight of 34.1kDa. The distribution is 2.42.

Embodiment 2

[0029] Dissolve 218.12 mg of pyromellitic dianhydride and 200.24 mg of 4,4'-oxybenzidine diamine in 5.0 mL of 1-butyl-3-methylimidazolium acetate ionic liquid; under stirring conditions, gradually heat to 80 degrees Celsius; after 8 hours of reaction, the separated solid was filtered and separated; the obtained solid was washed once with water, three times with methanol, and dried to obtain the product Kapton polyimide with a yield of 89%, an average molecular weight of 32.4kDa, and a molecular weight of 32.4kDa. The distribution is 2.24.

Embodiment 3

[0031] Dissolve 218.12 mg of pyromellitic dianhydride and 200.24 mg of 4,4'-oxybenzidine diamine in 5.0 mL of 1-ethyl-3-methylimidazolium hexafluorophosphate ionic liquid; under stirring conditions, gradually heated to 80 degrees Celsius; after 8 hours of reaction, the precipitated solid was separated by filtration; the obtained solid was washed with water once, washed with methanol three times, and dried to obtain the product Kapton polyimide with a yield of 42% and an average molecular weight of 16.1kDa, The molecular weight distribution was 2.23.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com