Modified regenerant and preparation method and application thereof

A technology of regeneration agent and modifier, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of restricting the development of heat regeneration technology and high price, and achieve the improvement of road performance, high temperature performance and dispersion ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Raw materials: 75 parts of plant asphalt, 20 parts of SBR latex, 4.2 parts of fatty alcohol and ethylene oxide condensate, 0.8 part of 2,6-tertiary butyl-4-methylphenol. The raw materials used in the present invention can be purchased from the market.

[0017] Method: Add plant asphalt into the stirring tank, heat to 80°C and stir, stir for 5 minutes, add SBR latex, stir for 60 minutes, stir and mix evenly, when the stirring tank is cooled to 60°C, add fatty alcohol and ethylene oxide condensate Continue to stir with 2,6-tertiary butyl-4-methylphenol for 20 minutes, and cool to normal temperature to obtain a liquid mixture to obtain a modified regeneration agent.

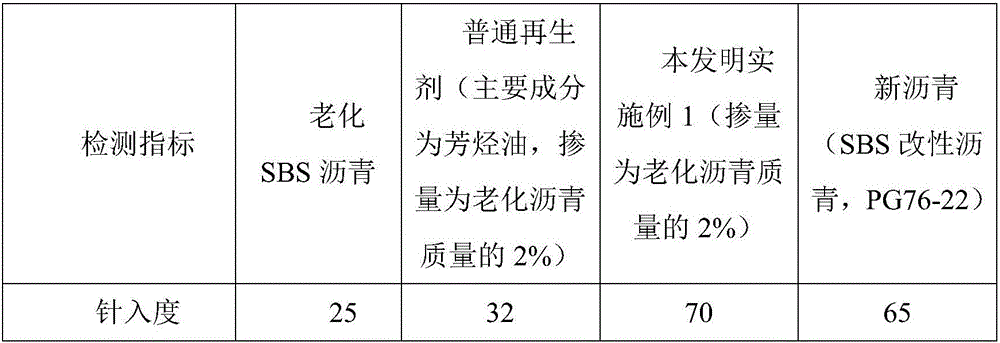

[0018] The modified regenerant prepared in Example 1 was subjected to an indoor regeneration performance test, and the obtained performance test results are shown in Table 1.

[0019] Table 1 Regenerant Performance Results of Regenerant

[0020]

[0021]

[0022] As can be seen from Table 1, the rejuv...

Embodiment 2

[0024] Raw materials: 72 parts of plant asphalt, 30 parts of VAE emulsion, 4.5 parts of fatty acid polyoxyethylene ester, 0.5 part of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide.

[0025] Method: Add plant asphalt into the stirring tank, heat to 70°C and stir, stir for 10 minutes, add VAE emulsion, stir for 30 minutes, stir and mix evenly, when the stirring tank is cooled to 50°C, add fatty acid polyoxyethylene ester and bis(3 , 5-tertiary butyl-4-hydroxyphenyl) sulfide continued to stir for 40 minutes, and cooled to room temperature to obtain a liquid mixture that obtained a modified regeneration agent.

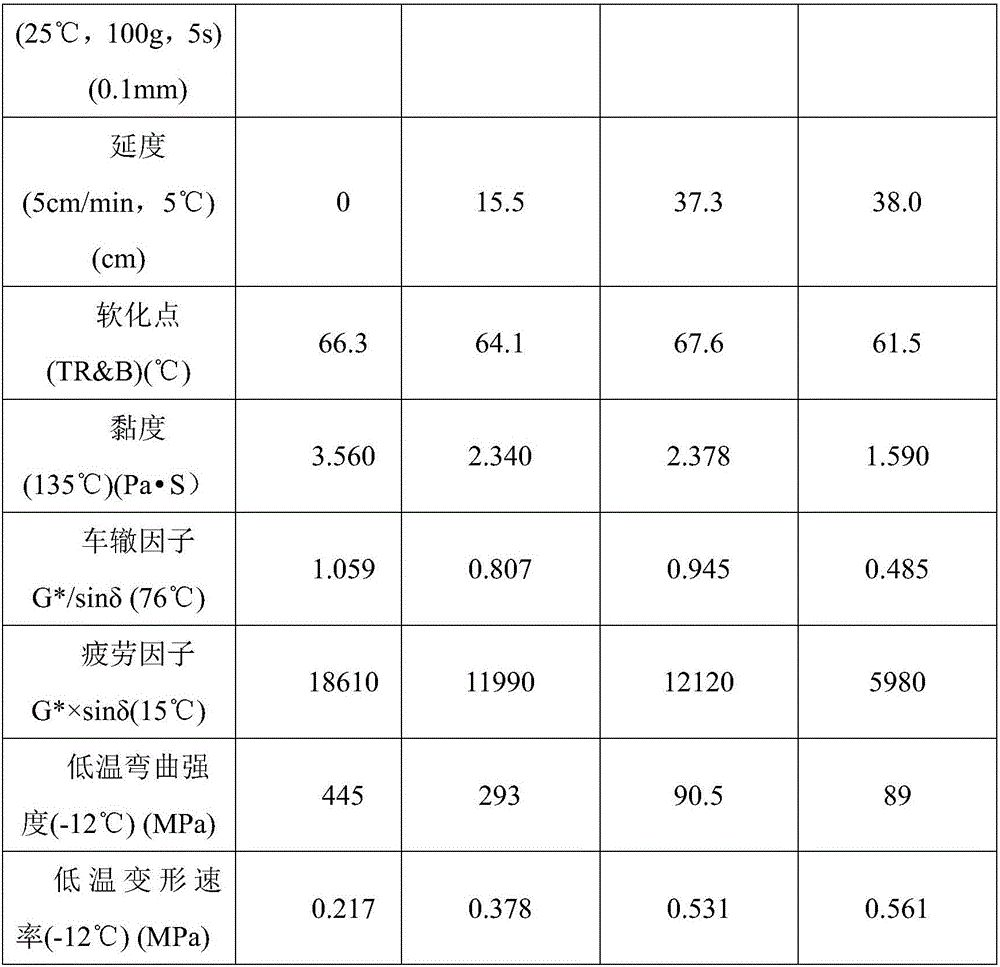

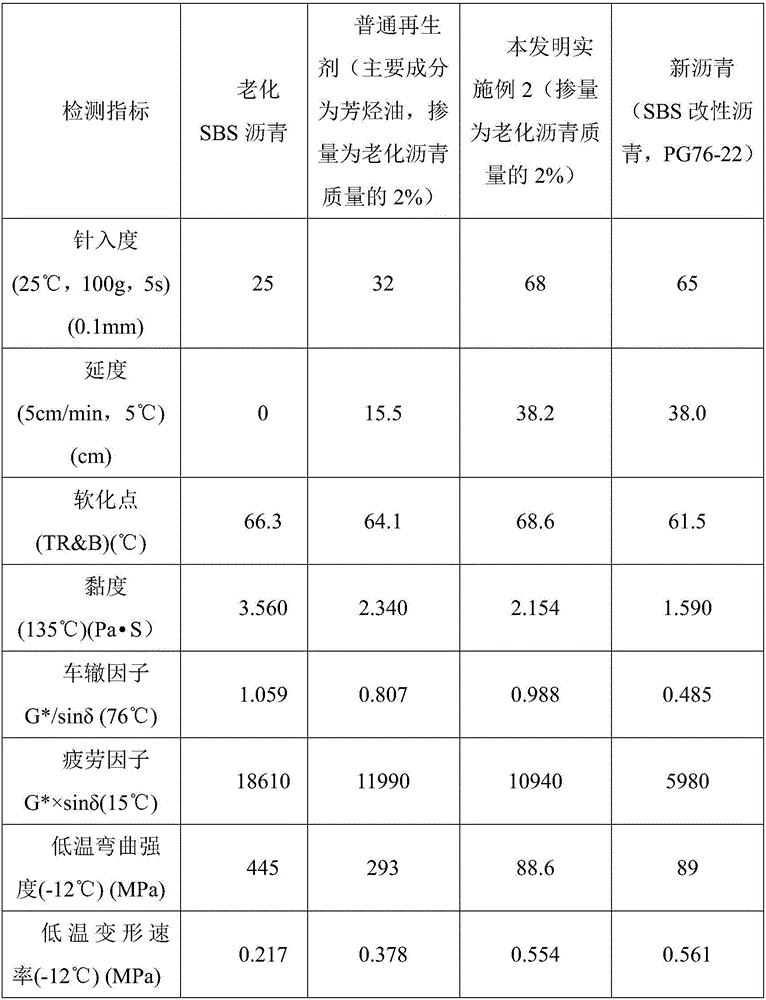

[0026] The modified regenerant prepared in Example 2 was subjected to an indoor regeneration performance test, and the obtained performance test results are shown in Table 2.

[0027] Table 2 Regenerant Performance Results of Regenerant

[0028]

[0029] As can be seen from Table 2, the rejuvenating agent provided by the present invention obviously improves the visco...

Embodiment 3

[0031] The basic steps are the same as in Example 1, except that the emulsifier adopts octylphenol polyoxyethylene ether, and the antiaging agent adopts tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionic acid] pentaerythritol esters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com