Waterborne wood paint adhesive force enhancement undercoat and topcoat

An adhesion-enhancing, water-based wood lacquer technology, applied in the field of wood lacquer, to achieve the effects of high hardness, good water resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

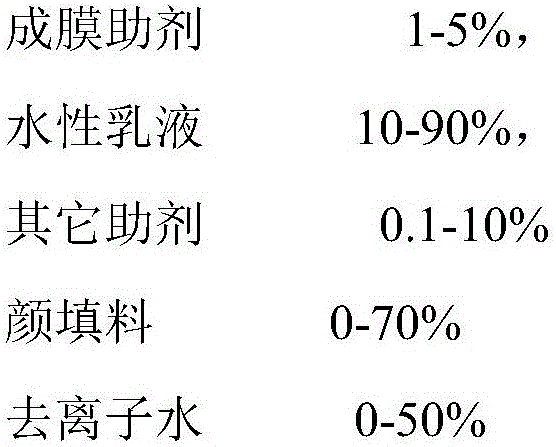

Method used

Image

Examples

Embodiment 1

[0015]

[0016]

[0017] To prepare the white primer, pass all the components through a disperser, disperse evenly, and pack to obtain the finished product. The present embodiment paint can be used as adhesion enhancing white primer and uses.

Embodiment 2

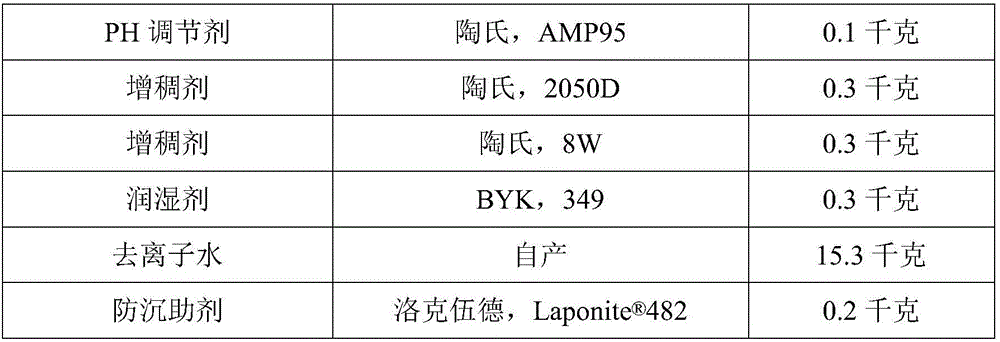

[0019]

[0020] To prepare the white finish paint, pass all the components through a disperser, disperse evenly, and pack to obtain the finished product. The present embodiment paint can be used as the white finish paint that adhesion enhances and uses.

Embodiment 3

[0022]

[0023] To prepare the clear primer, pass all components through a disperser, disperse evenly, and pack to obtain the finished product.

[0024] The present embodiment paint can be used as adhesion enhancing clear primer and uses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com