A method for manufacturing a welded steel pipe with ultra-high strength and high deformation performance

A technology for welding steel pipes and deformation performance, which is applied in the direction of manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of DWTT characteristics (deterioration of brittle crack propagation characteristics), and achieve excellent strength and toughness thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is a detailed description of the composition, structure and manufacturing method of the present invention. First, the component composition of the base steel sheet of the present invention will be described. As above, % refers to mass percentage.

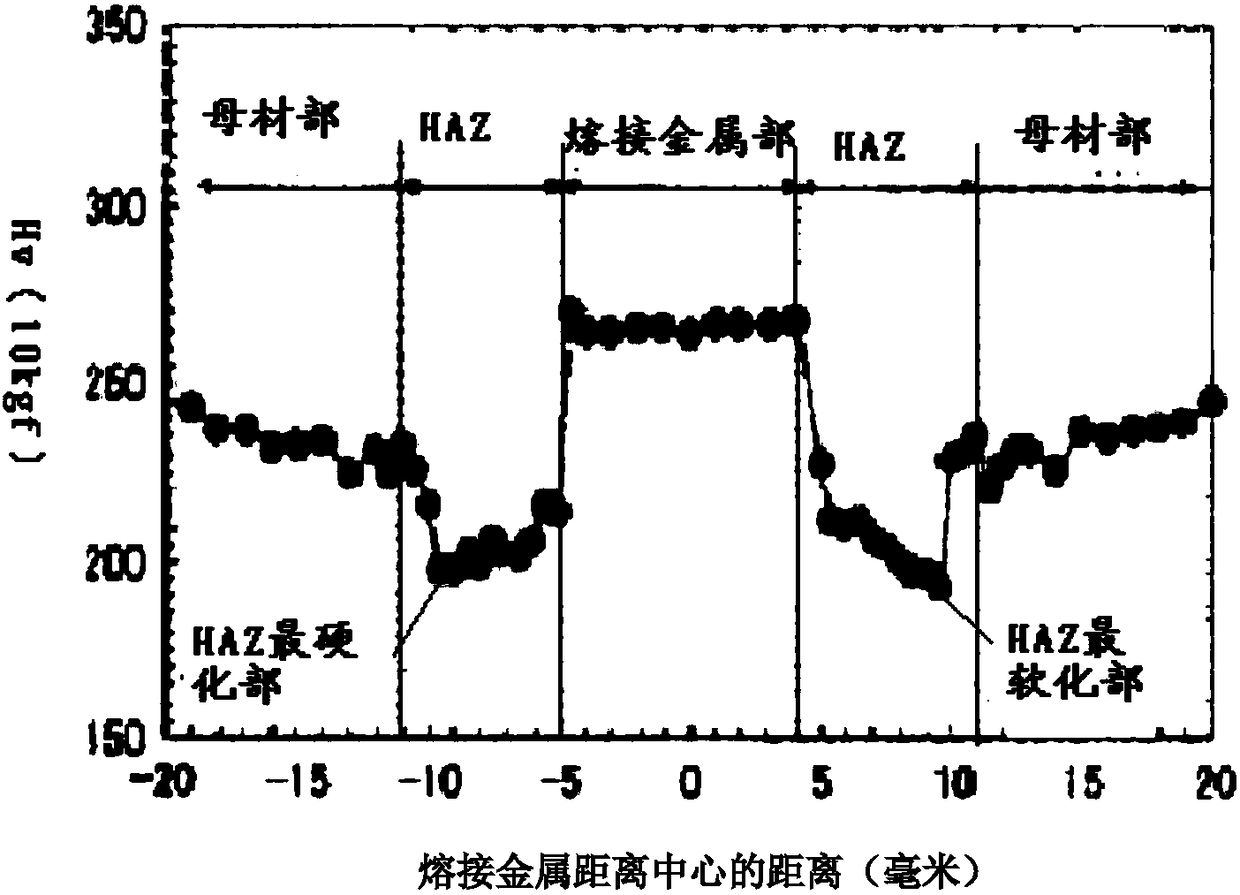

[0021] Through supersaturated solid solution treatment, C can improve the strength of low-temperature abnormal structure. To achieve this effect, its content must be above 0.03, but if it exceeds 0.09%, the hardness of the welded part of the steel pipe circumference will increase significantly, and low-temperature cracks will easily occur when processing steel pipes. Therefore, the C content is 0.03 to 0.09%.

[0022] Si is used as a deoxidizer and is an element that can increase the strength of steel after solid solution strengthening. To achieve this effect, its content must be more than 0.01%, but if it exceeds 0.4%, the toughness will be significantly reduced. Therefore, the Si content is 0.01 to 0.4%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com