Electrochemical rapid detection method for reinforcement corrosion degree in concrete structure

A technology for corrosion of concrete structures and steel bars, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, scientific instruments, etc. It can solve the problems of not giving the quantitative relationship of corrosion detection results, unclear influence degree of corrosion detection results, and limitations Research and other issues, to achieve the effect of simple and easy measurement method, fast measurement process and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Calculation example

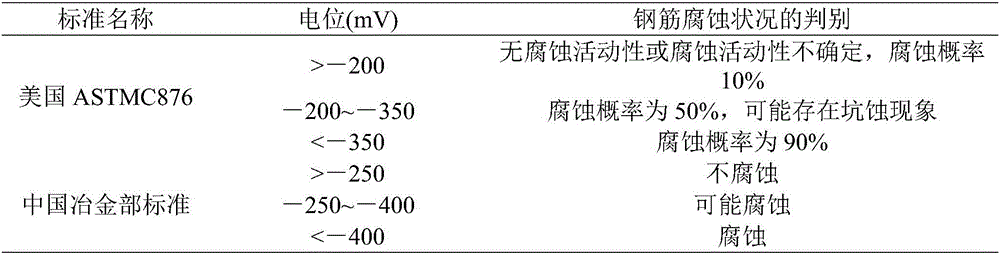

[0063] A reinforced concrete bridge has been built and put into use for 10 years. The concrete strength grade of the box girder is C30, and the thickness of the protective layer is 45mm. The half-cell potential method and the concrete resistivity method are used to detect the corrosion of steel bars in the box girder. The measured ambient temperature is 26°C, humidity is 50%, chloride ion concentration is 0.1%, concrete resistivity is 5kΩ.cm, and the steel bar corrosion potential is -310mV.

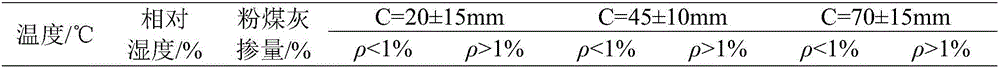

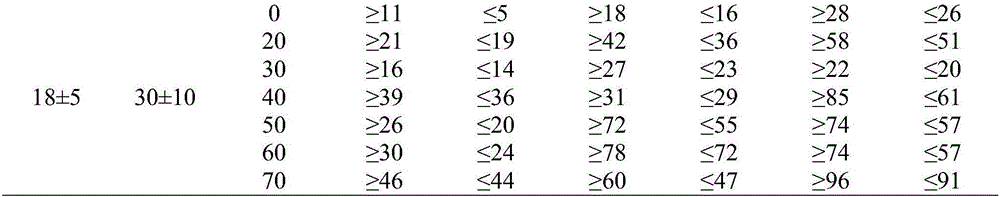

[0064] First, it is judged that the temperature and humidity are both non-standard conditions, and the temperature and humidity correction of the potential and resistivity is carried out to obtain the steel corrosion potential and concrete resistivity under standard conditions. From Table 6, when the protective layer is 45mm, the temperature and humidity correction coefficients of concrete resistivity are -0.2353 and -17.9963 respectively, and the temperature...

Embodiment 2

[0072] (1) The old Longwang River Bridge in Ganyu County, Lianyungang City was completed in 1999, and two piers were selected for steel corrosion testing. The measured ambient temperature is 22°C, the humidity is 78%, and the thickness of the concrete protective layer is 60mm.

[0073] By looking up Table 6, using the interpolation method, the potential temperature and humidity correction coefficients are -2.60402, -248.761, and the resistivity temperature and humidity correction coefficients are -0.25456, -20.6701, respectively. The measured values of potential and resistivity of No. 1 and No. 2 piers, the corrected values, and the evaluation of steel corrosion rate are shown in Table 7 to Table 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com