Alkali metal atomic magnetometer air chamber electric heating magnetic field measurement method

An atomic magnetic and magnetic field measurement technology, applied in the fields of atomic spin gyroscopes and atomic magnetometers, can solve the problems of low and in-situ measurement of measurement accuracy, and achieve the effect of improving measurement accuracy and eliminating position errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

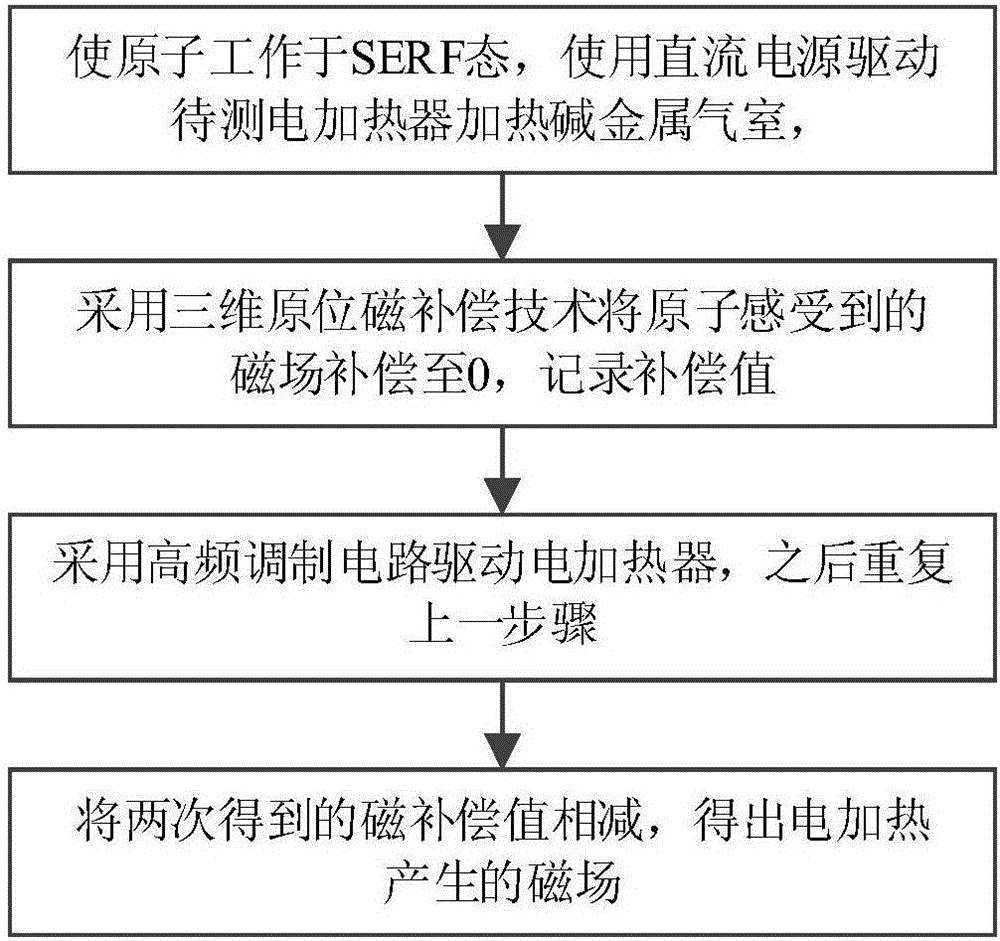

[0019] Such as figure 1 Shown, the specific implementation steps of the present invention are as follows:

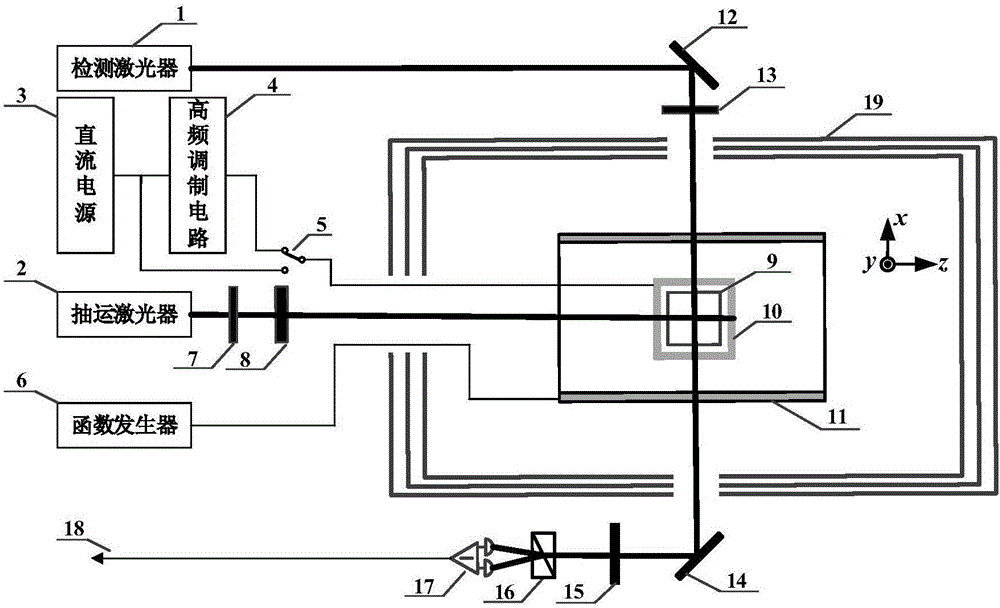

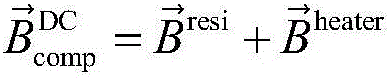

[0020] (1) The alkali metal gas chamber 9 is installed in the magnetic shielding barrel 19, so that the atoms work in a low magnetic field environment to realize the SERF state. Switch the switch 5 to the DC power supply 3 to drive the electric heater 10 to be tested, use the electric heater 10 to heat the alkali metal gas chamber 9, and make the alkali metal atomic number density in the alkali metal gas chamber 9 reach 10 13 ~10 14 piece / cm 3 level and reach a steady state.

[0021] The laser output from the pumping laser 2 passes through the polarizer 7 and the 1 / 4 wave plate 8 successively, and becomes circularly polarized light to irradiate the alkali metal gas chamber 9 to realize the pumping of atoms. The laser output from the detection laser 1 successively passes through the reflector 12 and the polarizer 13 to become linearly polarized light, and then enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com