Semi-aromatic polyamide resin composition and molded article obtained by molding same

A polyamide resin and semi-aromatic technology, which is applied in the field of semi-aromatic polyamide resin compositions, can solve the problems of poor surface appearance and reduced fluidity of the molded body, and achieves excellent molding processability and improved retention stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0152] 100 parts by mass of semi-aromatic polyamide (A-1), 1 part by mass of azine-based dye (C-1), and 0.5 part by mass of antioxidant (F-1) were dry-blended, and a weight loss compensation method was used. Type CE-W-1 type continuous quantitative supply device (manufactured by Kubota Corporation) is used for metering, and it is supplied to the main supply port of a co-rotating twin-screw extruder TEM26SS type (manufactured by Toshiba Machinery Co., Ltd.) with a screw diameter of 26mm and L / D50. Melt kneading is carried out. On the way, 20 parts by mass of the fibrous reinforcement (B-1) was supplied from the side feed port, and kneaded further. After being drawn into a thread form from a die, it was cooled and solidified in a water bath, and cut with a pelletizer to obtain semi-aromatic polyamide resin composition pellets. The barrel temperature of the extruder was set at (Tm+15° C.), the screw speed was 250 rpm, and the discharge rate was 25 kg / hour.

Embodiment 2~30

[0153] Examples 2-30, Comparative Examples 1-10

[0154] Except having changed the composition of the semi-aromatic polyamide resin composition as shown in Table 2, 3, operation similar to Example 1 was performed, and the semi-aromatic polyamide resin composition pellet was obtained.

[0155] Various evaluation tests were performed using the obtained semi-aromatic polyamide resin composition pellets. The results are shown in Tables 2 and 3.

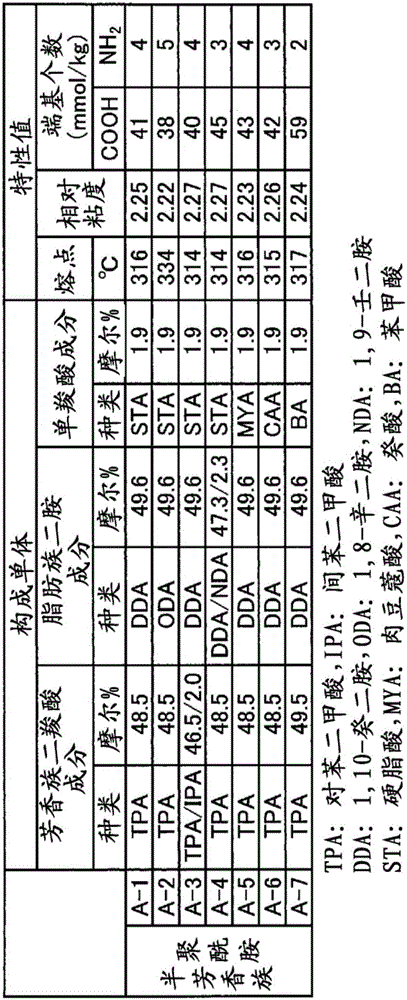

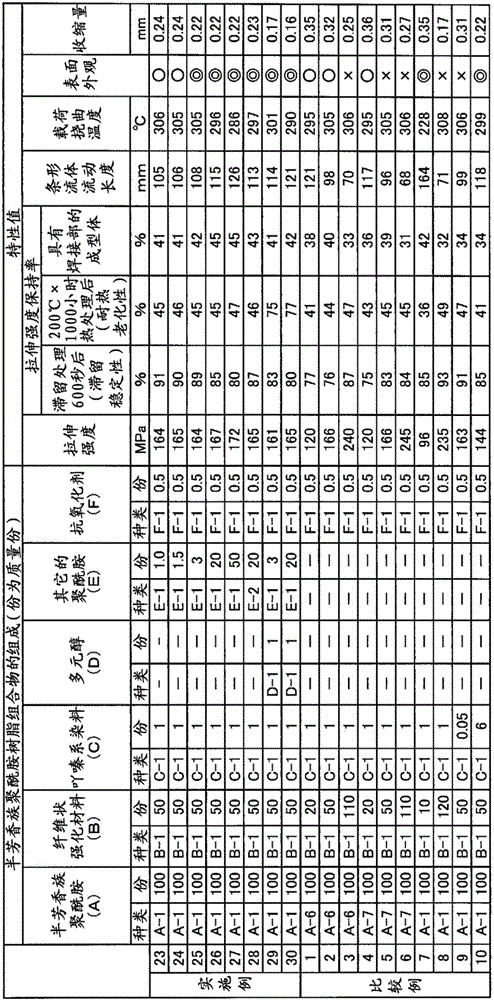

[0156] [Table 2]

[0157]

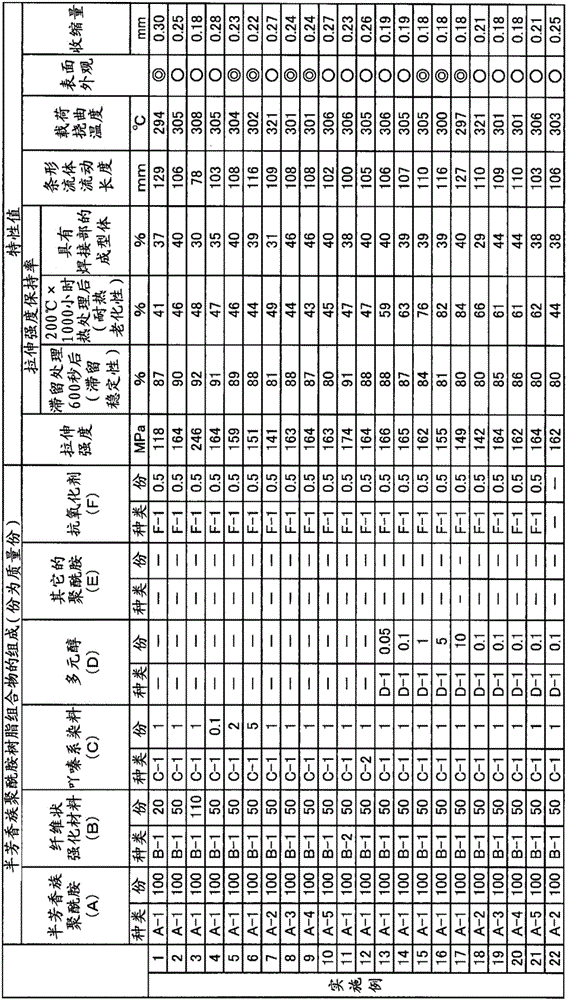

[0158] [table 3]

[0159]

[0160] Since the resin compositions of Examples 1 to 30 satisfy the requirements of the present invention, the retention rate of tensile strength after 600 seconds of retention treatment is high, the retention stability is excellent, and the flow length of the strip-shaped fluid is long, and the load of the obtained molded article is high. High deflection temperature and excellent heat resistance, high tensile strength retention rate after heat treatment at 200°C×1000 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com