Process for reducing the amounts of zinc (Zn) and lead (Pb) in materials containing iron (Fe)

A technology of total weight and oxidant, applied in the direction of improving process efficiency, etc., can solve problems such as unoptimized, and achieve the effects of preventing formation and release, stable reaction, and good iron recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

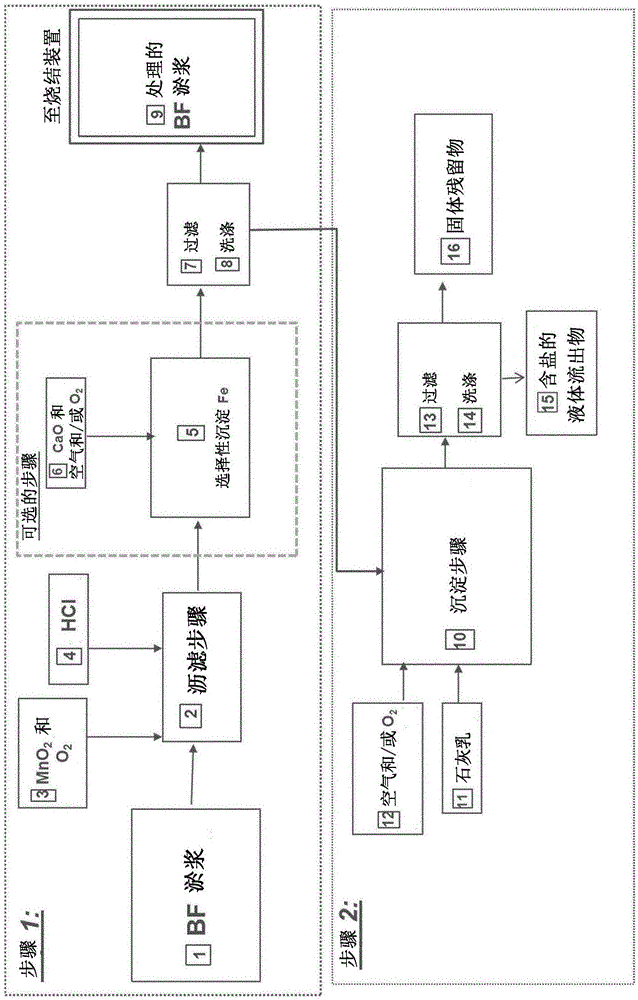

Method used

Image

Examples

Embodiment

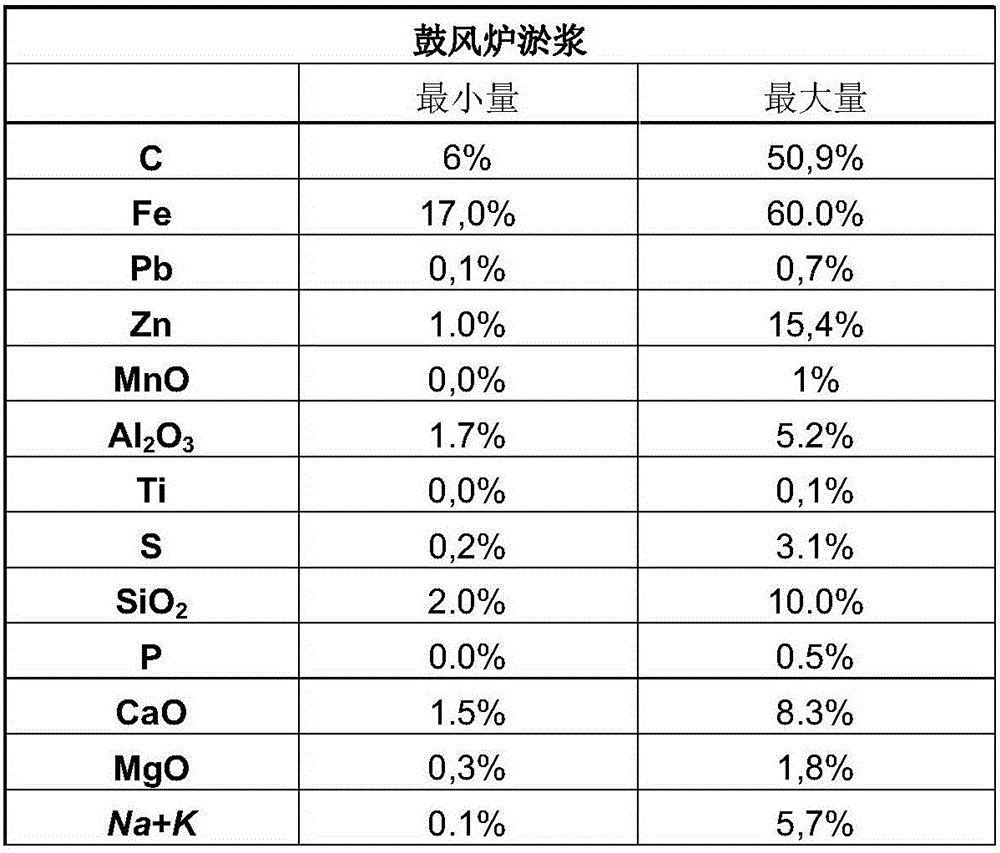

[0137] Example : To treat 1 ton of blast furnace slurry with a composition of Fe 25%, C 45%, Zn 3,5% and Pb 0,5%, 0.50 tons of HCl 32% can be added to achieve a pH of about ~1.5 and a certain amount of manganese (IV) (Mn / Zn molar ratio is about 0.6). At the end of step n ° 1, about 0.9 tons of treated blast furnace slurry forming a filter cake (Fe by-product) containing about 26 wt% Fe, 50 wt% C, less than 0.3 wt% Zn, less In 0.1wt% of Pb and less than 0.5wt% of Cl. This content of Cl is obtained by washing on a filter press with water in an amount of 1-2 L / kg Fe / C. The amount of solution recovered was ~4m 3 (filtrate + wash water).

[0138] To recover dissolved metals, the solution of filtrate and wash water is then submitted to a precipitation step. The amount of milk lime 25% to achieve pH ~ 9 and precipitate all metals dissolved in the solution (filtrate and wash water) is preferably about 720 kg. Then, the resulting mixture was filtered and washed with an amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com