Steel material for induction hardening

A high-frequency quenching and steel technology, applied in the field of power transmission parts and high-frequency quenched steel, can solve the problems of unclear, no case-hardening steel machinability comparative research, etc., and achieve excellent surface hardness and excellent machinability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133] Next, examples of the present invention will be described. The production conditions in the examples are examples of conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to the examples of conditions. The present invention can employ various conditions as long as the object of the present invention is achieved without departing from the gist of the present invention.

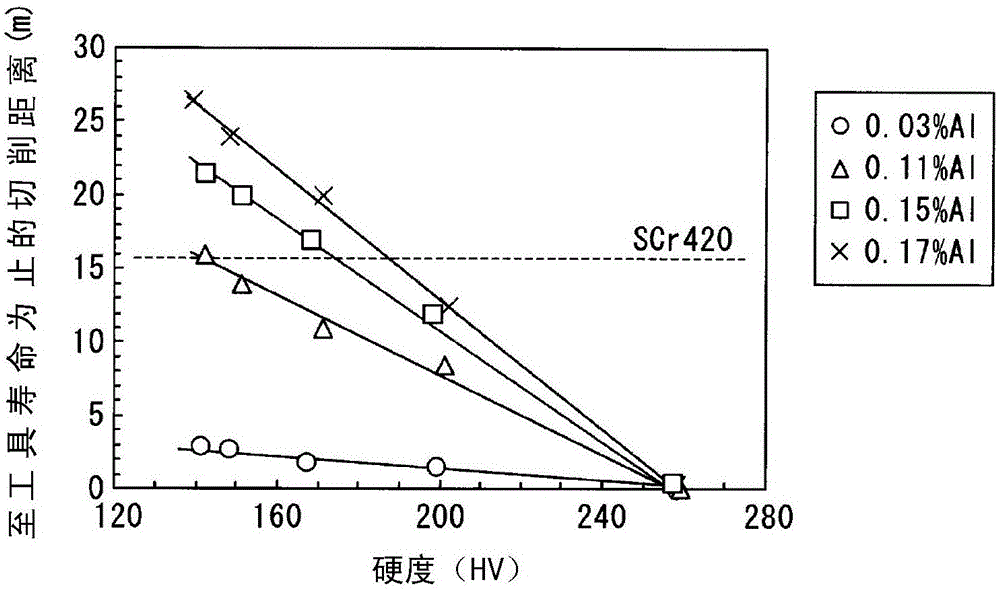

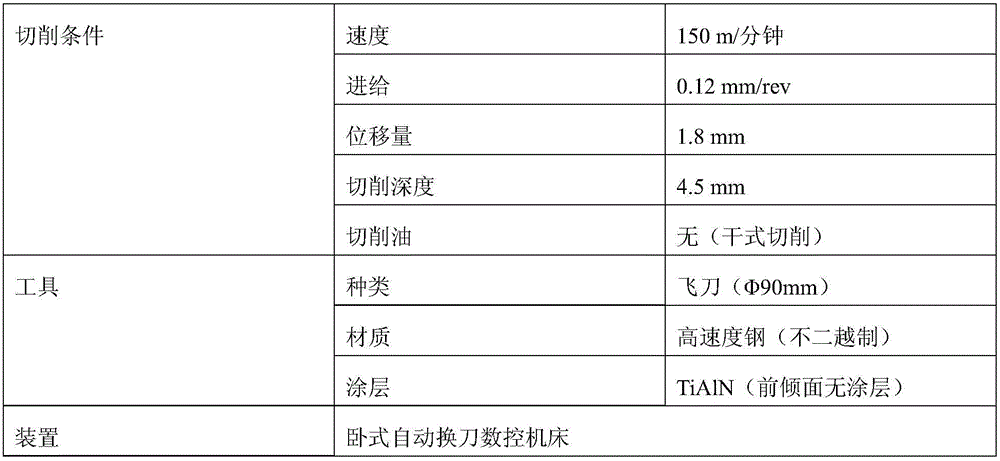

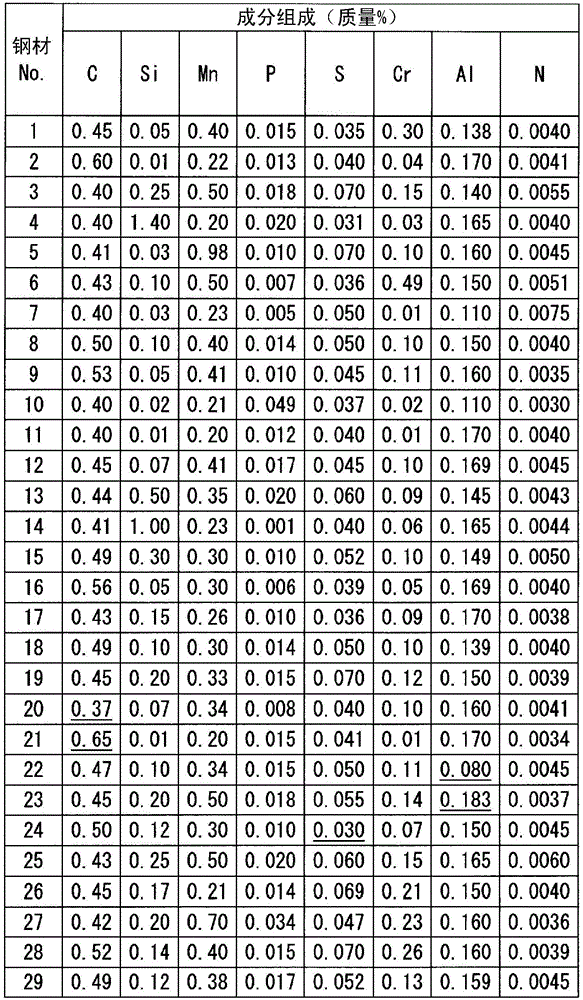

[0134] Steels having the chemical compositions shown in Table 2-1 and Table 2-2 were melted. When casting steels 1 to 28, the cooling rate from the liquidus temperature to the solidus temperature in the 1 / 4 part in the thickness direction of the slab is controlled at 10 to 100°C / min. , set the cooling rate below 10°C / min. The cooling rate at the time of casting of each steel described in Table 2-1 and Table 2-2 was estimated based on the average pitch of secondary dendrite arms before hot working of each steel. After casting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com