Patents

Literature

191 results about "Sulphide compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oilwell sealant compositions comprising alkali swellable latex

Sealant compositions comprising an alkali swellable latex and a pH increasing material and methods of using the same to service a wellbore are provided. In one embodiment, the sealant composition can be used in a wellbore and includes an alkali swellable latex and a pH increasing material. The sealant composition can have a pH of from about 7 to about 14. In other embodiments, the pH increasing material includes a base-producing material. The base-producing material can include alkali and alkali earth metal carbonates, alkali and alkali earth metal bicarbonates, alkali and alkali earth metal hydroxides, alkali and alkali earth metal oxides, alkali and alkali earth metal phosphates, alkali and alkali earth metal hydrogen phosphates, alkali and alkaline earth metal sulphides, alkali and alkaline earth metal salts of silicates, alkali and alkaline earth metal salts of aluminates, water soluble or water dispersible organic amines, polymeric amine, amino alcohols, or combinations thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

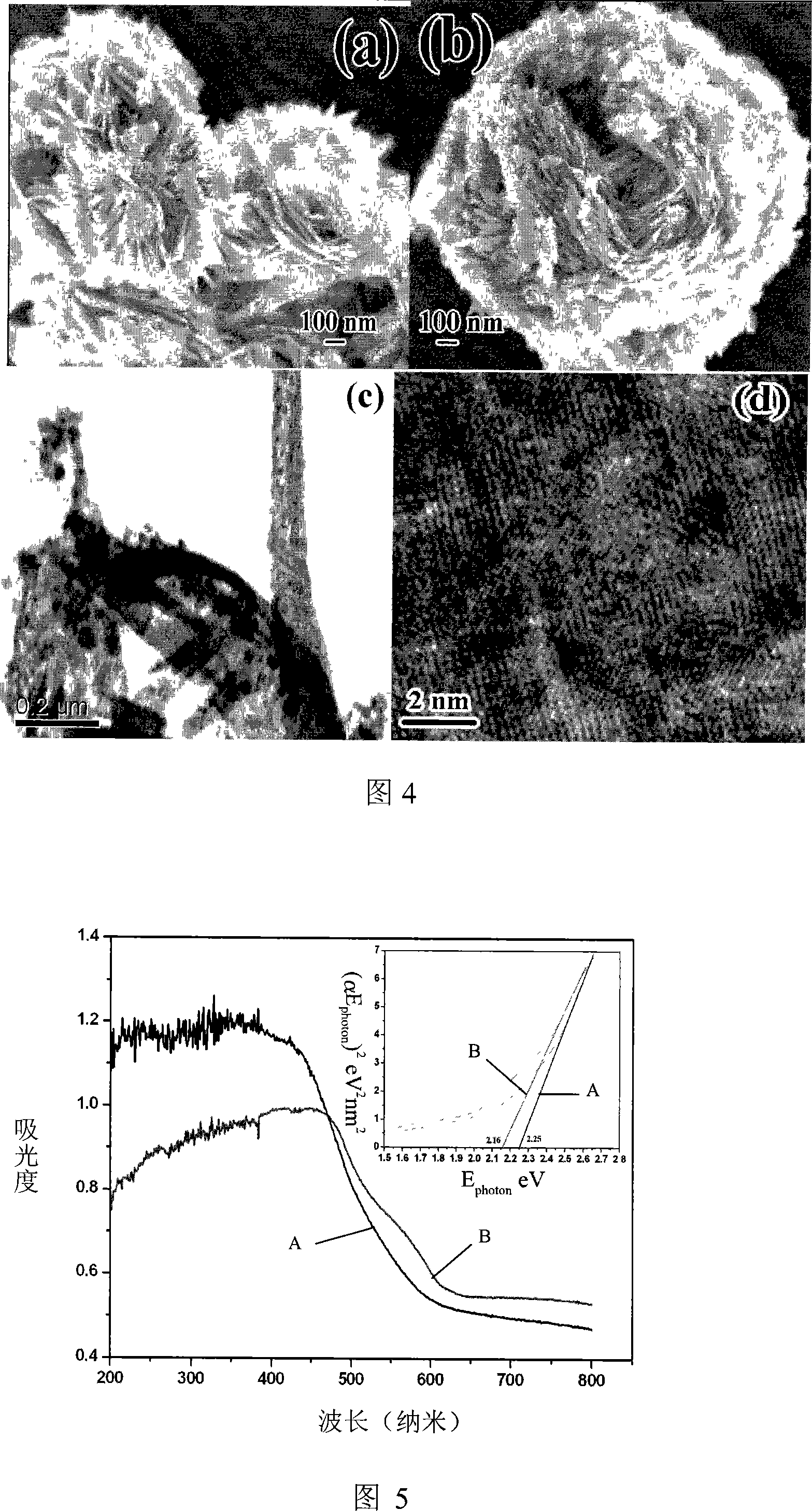

Preparation method of quantum dot self-assembling nano structural material

The invention discloses a preparation method of a super nanostructure material formed by quantum dots self-assembly. That the alcohols are used as solvent to prepare nano-metal oxides and sulphides or metal oxides and sulphides are reduced to get nano-metal is a widely used method. The super nanostructure material formed by the quantum dots self-assembly draws much attention because of the superior comprehensive properties. The application prospect is wide enough. The invention adopts a method of using the alcohols as the solvent that a super nanostructure with different appearances and is formed by the quantum dots self-assembly which is obtained by changing the condition under the existence condition of surfactant. According to the invention, precursor, namely organic metal compound is dissolved in the alcohol solvent by ultrasonic, stirring and being laid down quietly. Under the effect of the surfactant, the precursor has a nucleation and grows into a plurality of quantum dots, the size of which is similar to nano. Then the dots form a super nanostructure which has a certain shape or space structure along the defined growing direction of the surfactant.

Owner:HUAZHONG NORMAL UNIV

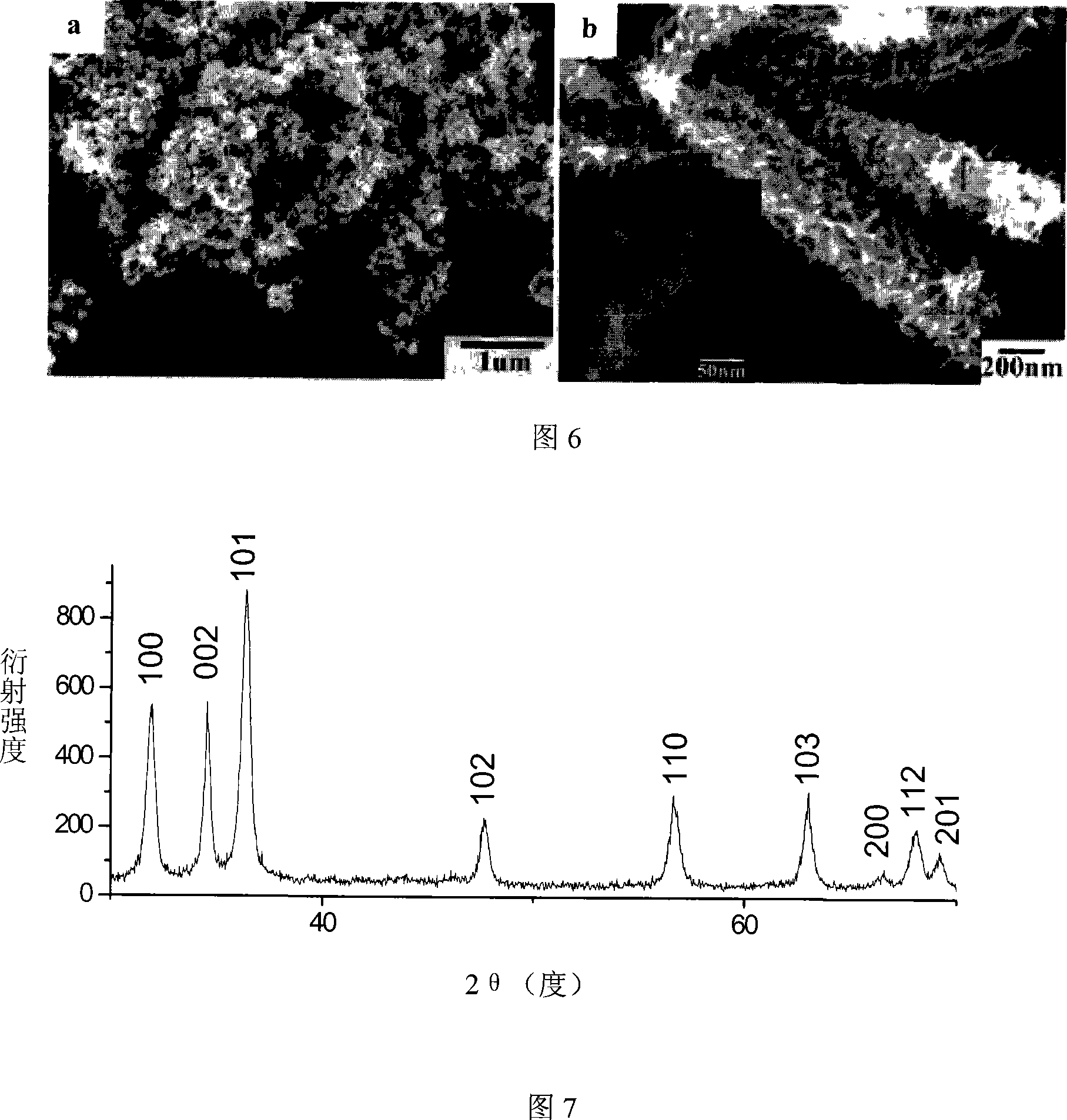

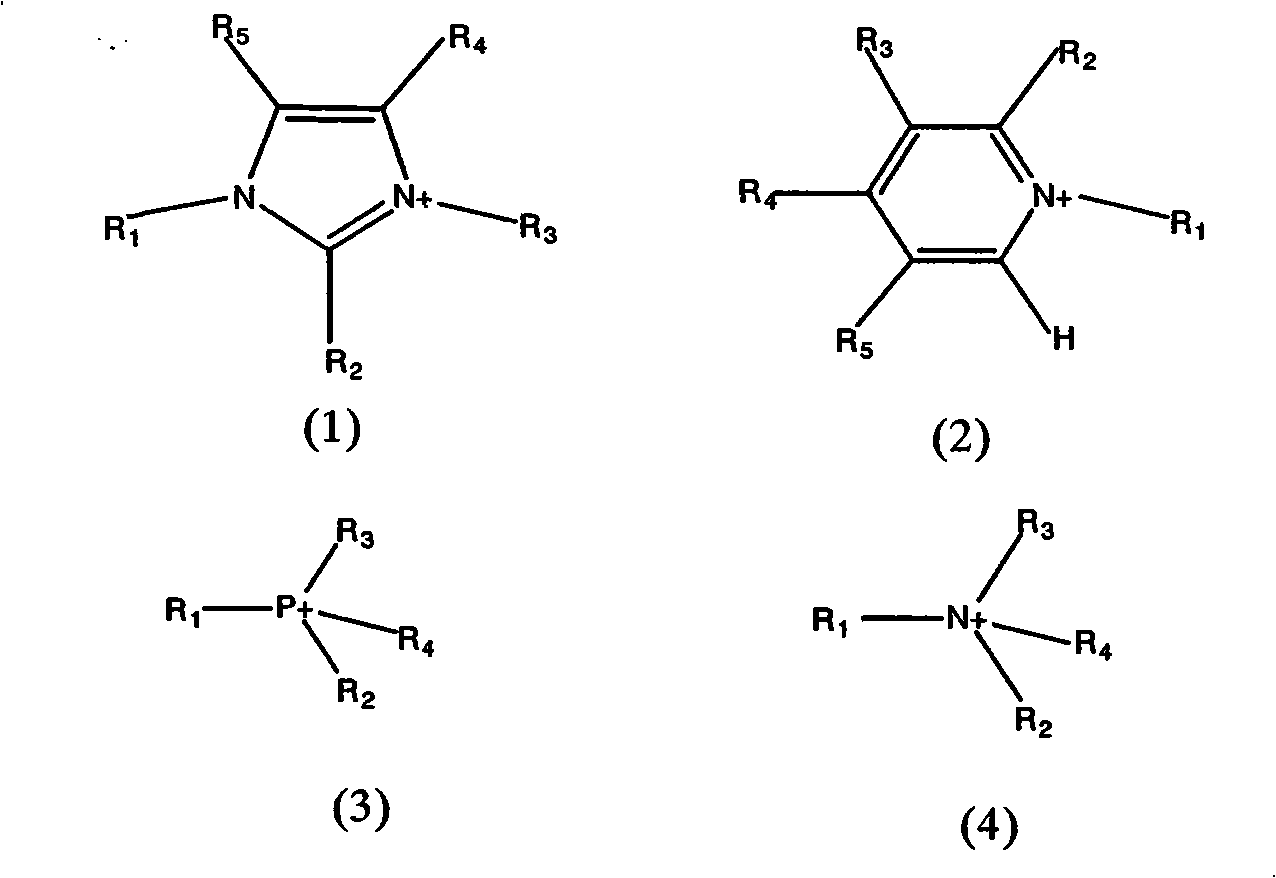

Lithium-sulfur system solid electrolyte material for all solid state lithium battery and preparation method

ActiveCN101013753ARich structure typeImprove ionic conductivitySolid electrolyte cellsSulfide conductorsCrystal systemAll solid state

The invention relates to one solid electrolyte materials and its process method for fix lithium battery, which is characterized by the following:four types of different sulfur compounds as Li2S:A / S:P2S5=6:0.1-4.0:1.5 for compound to form non-crystal system to provide more effective paths for lithium ion transmission to get higher ion conductive rate; the said A for Ag, Zn, Al or Zr with sample of Li2S-ZrS2-P2S5 with room ion battery conductive rate as 9.60X10-6S / cm and lower electron conductive rate under 150 degrees for 3.30X10-4S / cm.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

New method for desulfurization by oxidation based on alkaline ionic liquid catalyst

The invention provides a new method for desulfurization by oxidation based on alkaline ionic liquid catalyst. The method comprises the steps as follows: using an absorbent to selectively absorb sulfur compounds, using alkaline ionic liquid as a main catalyst, adding other ionic liquid as a catalyst accelerator, and finally, catalytically oxidising the reductive sulfur compounds in the presence of an oxidant. The method can be used for removing sulphides in gases or wastewater and recovering sulfur. The method has a simple technology, and the catalyst and the absorbent can both be regenerated and recycled, and the recovery rate of elemental sulfur can be more than 85(wt)%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

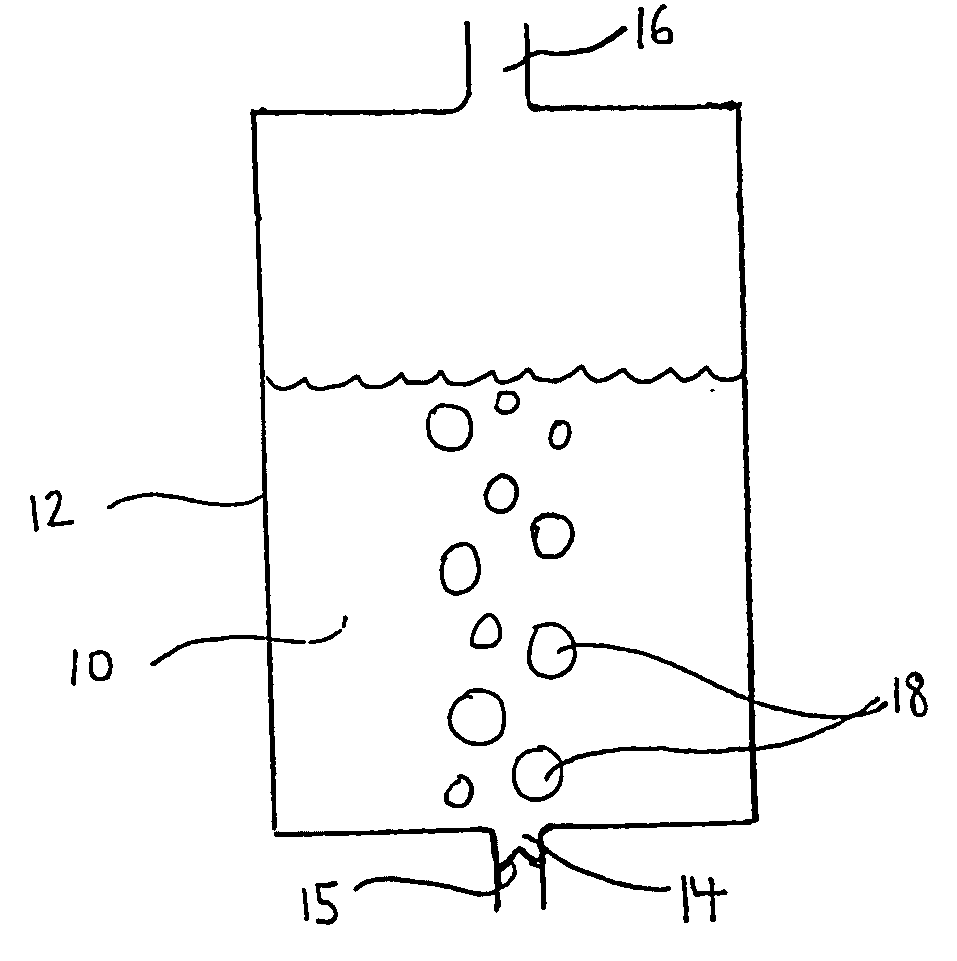

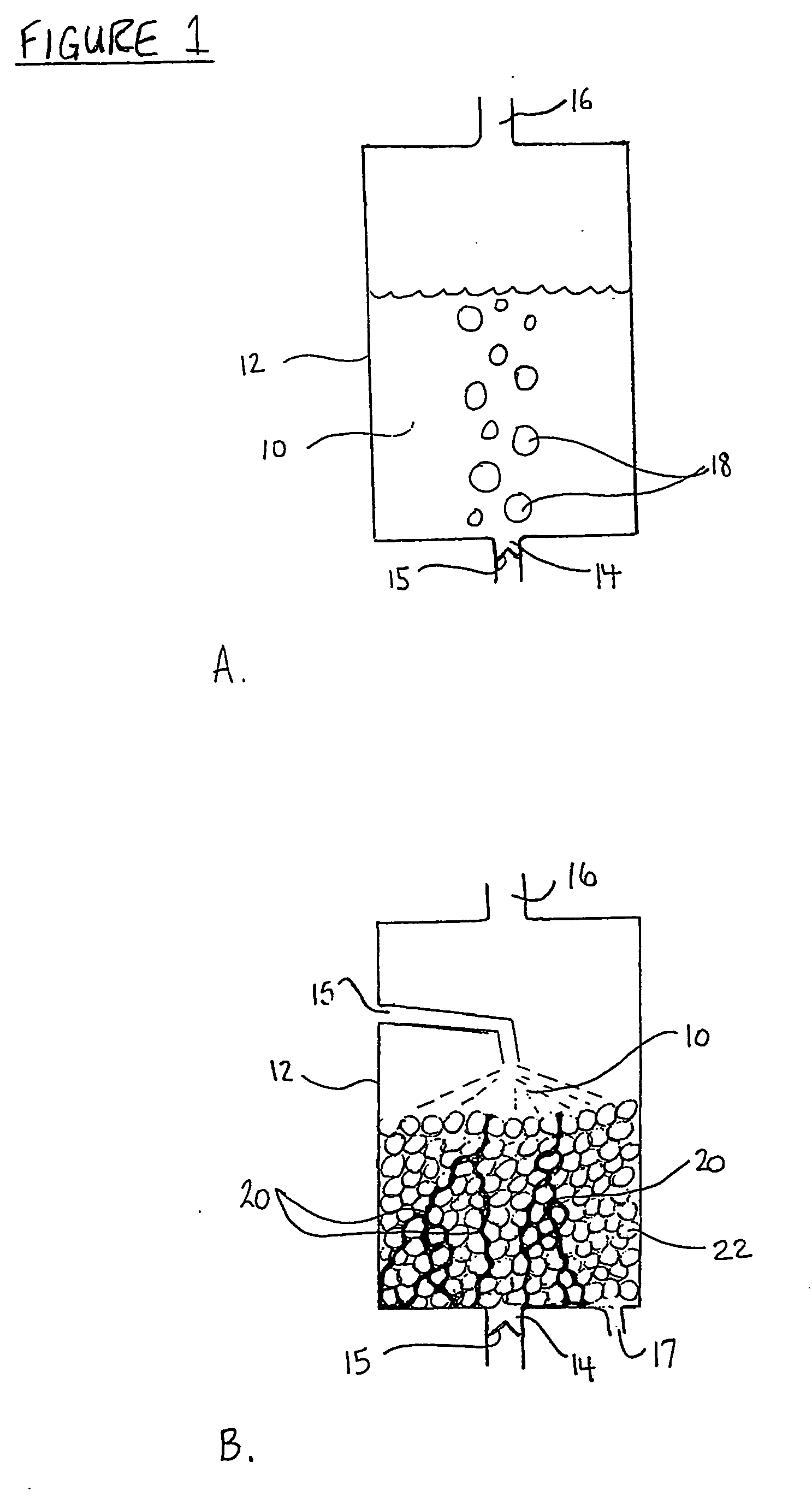

Liquid and solid effluent treatment process

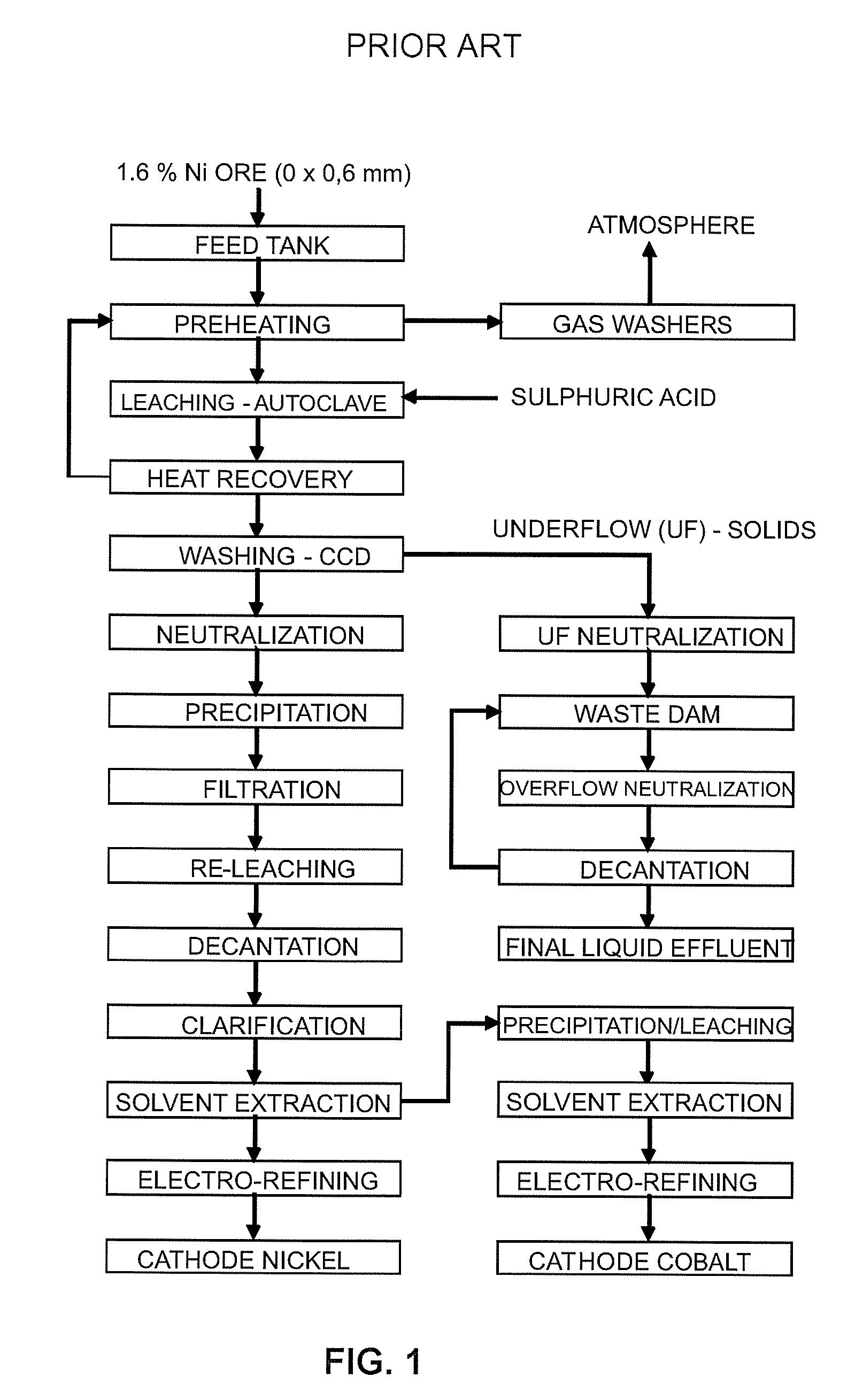

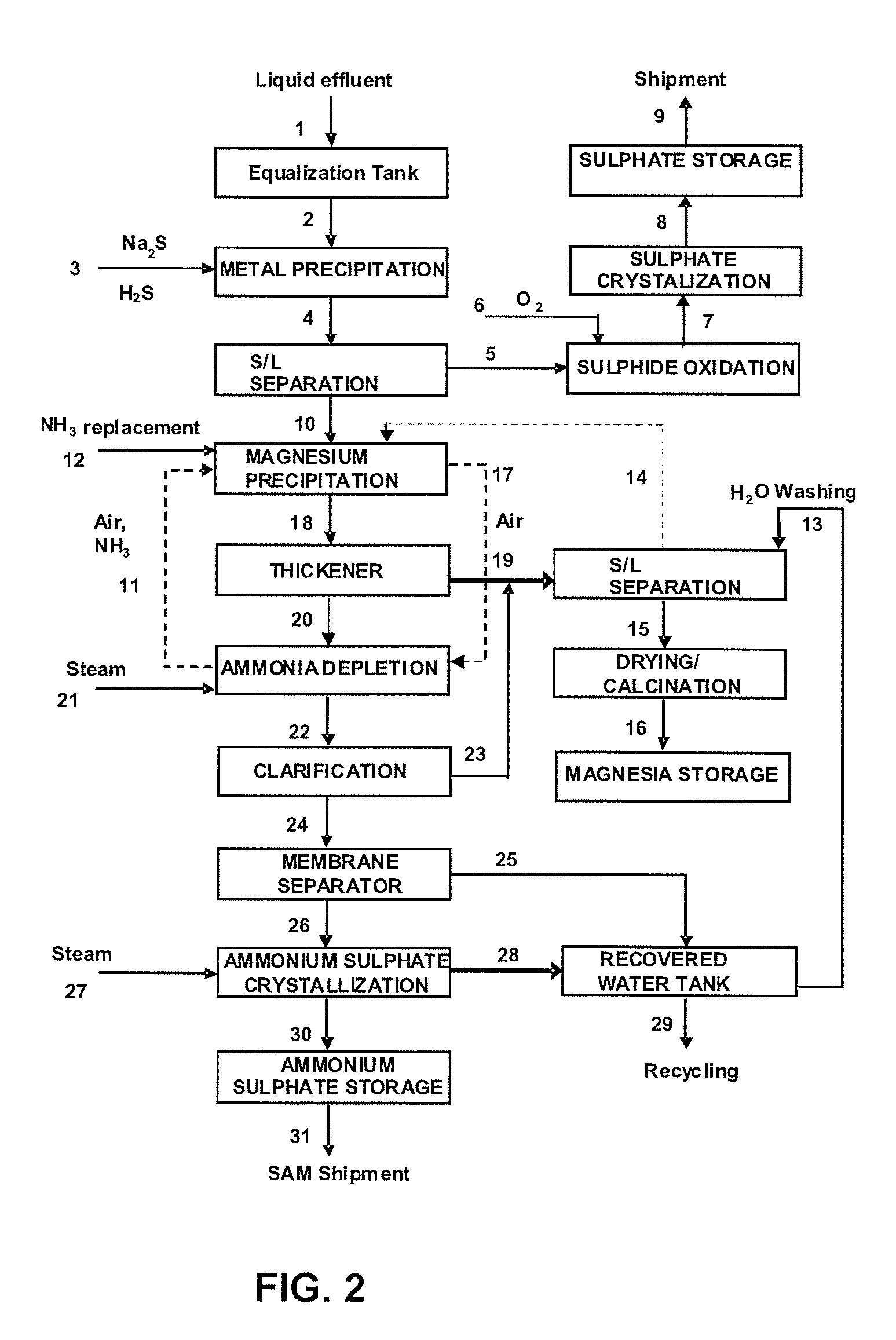

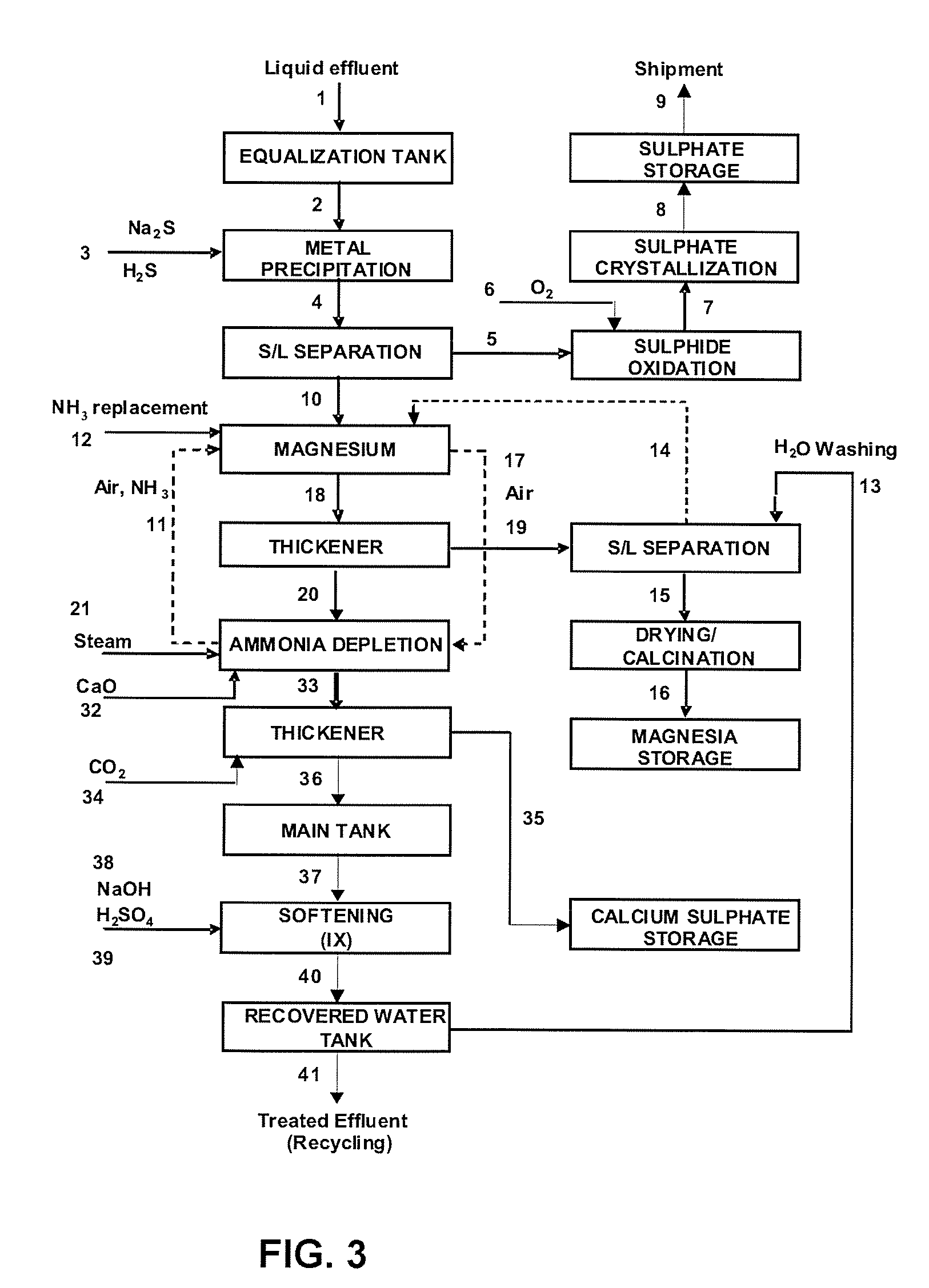

ActiveUS20090180945A1Reduce consumptionReduce environmental impactCobalt ammonia complexesNitrogen compoundsAmmonium sulfateChemistry

A process for recovering metals such as Ni, Co, Mn, Cu, Zn, among others, through precipitation as sulphides, enabling recovery of magnesium in the form of hydroxide, carbonate and oxide and providing recovery of sulphate as gypsum and ammonium sulphate. Liquid phase, after full treatment, comprises recovered water with a quality proper for total reuse in industrial process.This process of liquid and solid effluent treatment is provided with flexibility to process several types of effluents presenting wide variations in their chemical composition. The main steps of this process are: (1) equalization of liquid effluent, (2) precipitation of metals as sulphides, (3) oxidation of metallic sulphides and crystallization as metallic sulphates, (4) precipitation of magnesium as hydroxide and calcination thereof into magnesium oxide (5) recovery of ammonia, (6) preconcentration of the remaining saline solution, (7) evaporation / crystallization of ammonium sulphate, (8) storage of recovered water, (9) partial or total precipitation of sulphate contained in the effluent with quicklime, (10) segregated storage of gypsum and gypsum-magnesium mixture, (11) softening of the remaining solution and (12) storage of softening water.

Owner:VALE CANADA

Method of converting feeds from renewable sources in co-processing with a petroleum feed using a catalyst based on nickel and molybdenum

InactiveUS20120216450A1Eliminate the effects ofImprove low temperature performanceLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionKeroseneSulfur

The invention relates to a method of hydrotreatment in co-processing of petroleum feeds, in a mixture with at least one feed obtained from renewable sources, for producing fuel bases (kerosene and / or gas oil) having a sulphur content below 10 ppm, said method comprising the following stages:a) a first hydrotreatment stage in which said feed passes through at least one first fixed-bed catalytic zone comprising at least one bulk or supported catalyst comprising an active phase constituted by at least one group VIB element and at least one group VIII element, said elements being in the form of sulphide and the atomic ratio of the group VIII metal (or metals) to group VIB metal (or metals) being strictly greater than 0 and less than 0.095,b) a second hydrotreatment stage into which the effluent from the first hydrotreatment stage is sent directly, and in which said effluent passes through at least one second fixed-bed catalytic zone comprising at least one hydrotreatment catalyst.

Owner:INST FR DU PETROLE

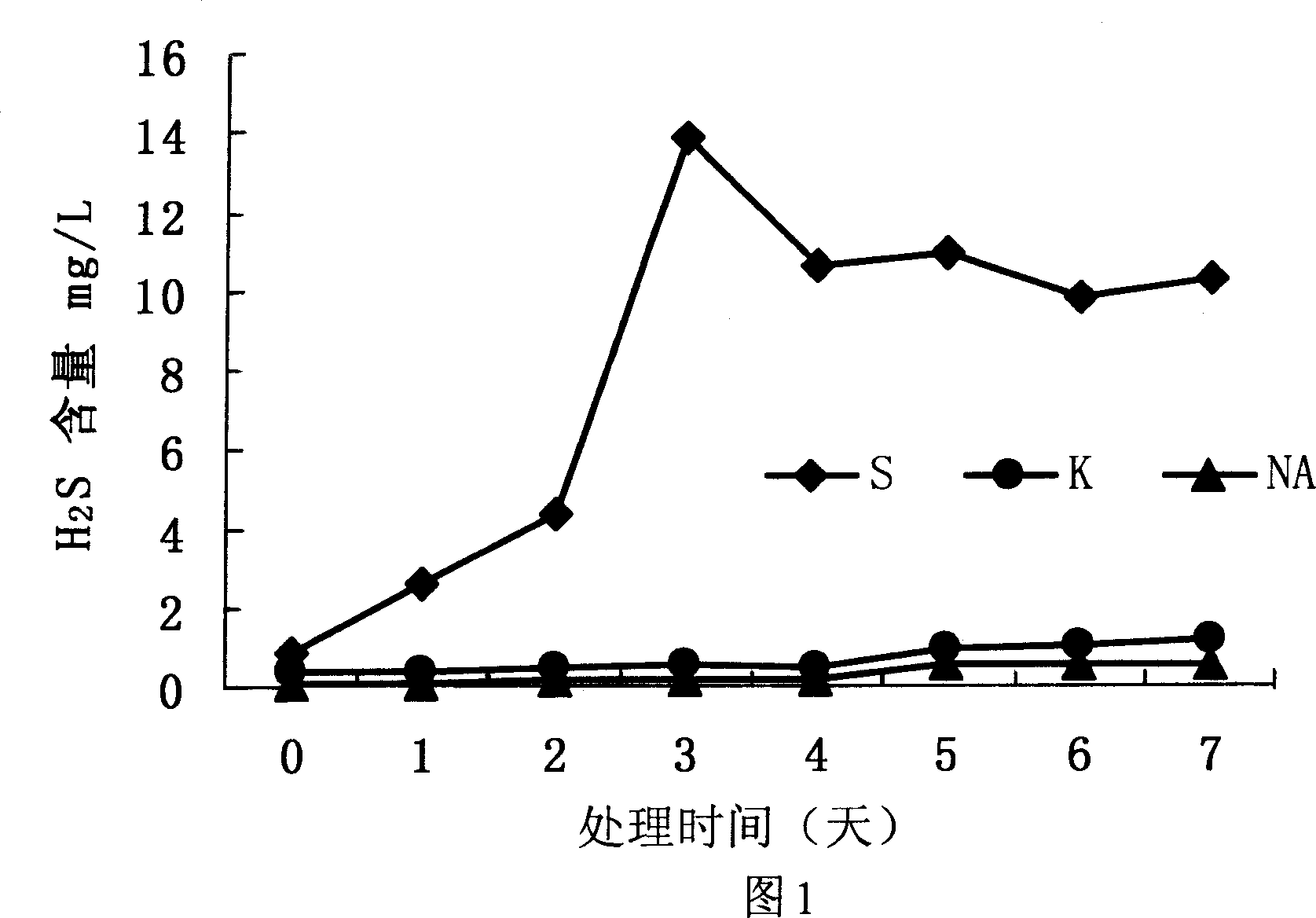

Microorganism for controlling harm of oil field sulfate reductive bacterium and application thereof

InactiveCN1920004AReduce corrosion costsEliminate pollutionBacteriaBiological water/sewage treatmentMetaboliteDenitrifying bacteria

The invention relates the microorganism agent used to control oil field sulfate-reducing bacteria and its application. The invention can used to control oil field secondary depletion sulfate-reducing bacteria and microorganism. The water outlet system of secondary depletion technology comprises sulfate-reducing bacteria, H2S and sulphide, which can cause corrosion and pollution of sulphide. Microorganism agent comprises denitrifying bacteria culture, nutrescin and synergic nutrescin. 0.01-1wt% denitrifying bacteria culture, 5-100g / L culture and 10-200ppm synergic nutrescin. Microorganism agent can avoid SRB growing, SRB producing H2S, and removing sulphide. At the same time, metabolite can improve recovery efficiency.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Hydrothermal synthetic method for coating carbon nanometer tube with molybdenum sulphide

InactiveCN1613918AReduce usageLow reaction temperaturePigment treatment with non-polymer organic compoundsThioureaCarbon nanotube

Compound nano pipes coated by molybdenum sulphide are produced by water heating synthesis, including: first to put the molybdate and thiourea in the water and the mass percent of molybdate is 0.2%-1.5%, the thiourea is 0.2%-2.0%, then disperse the nano pipes of C in the solvent by the super sonic wave, and the mass percent of it is 0.1%-0.5%, the mixture is then put into the non-corrosive steel tank which is full of Teflon to react, at 200-250deg.C for 20-40h. The 2-6 phase of molybdenum sulphide obtained by the transmission electron microscopic and energy scattering analyze. They can be used to prepare high performance compound material of tribology, catalytic carrier, and microprobe. The process is simple, and it could avoid using the H2S.

Owner:ZHEJIANG UNIV

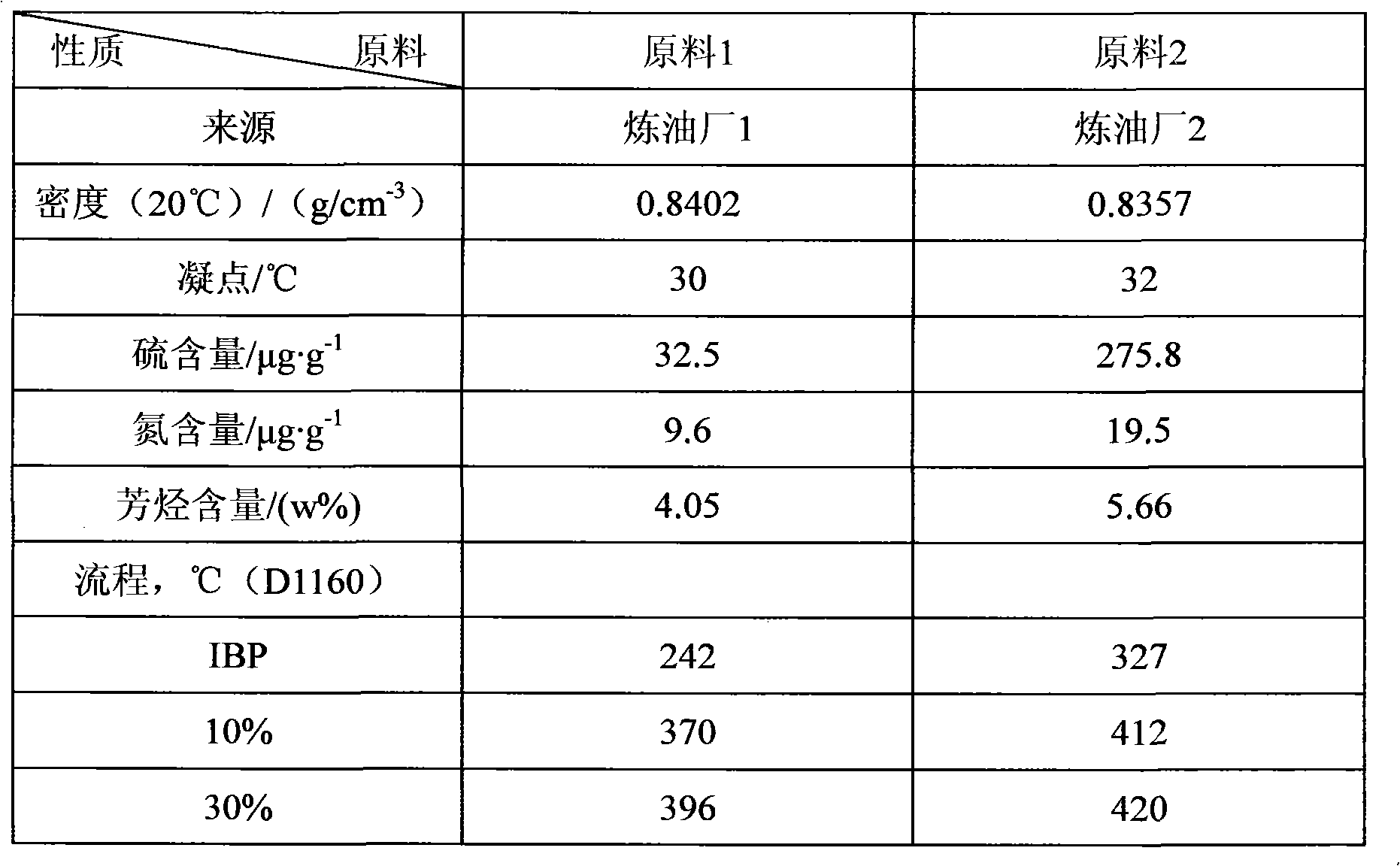

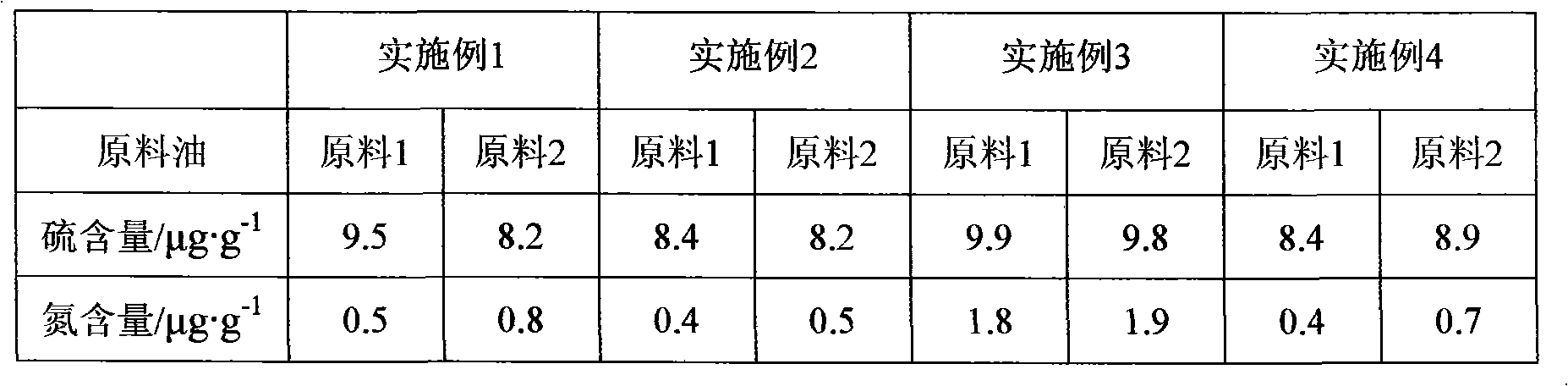

Hydrocracking tail oil ultra-deep adsorbent desulfurizing and denitrifying method

The invention discloses a hydrocracking tail oil ultra-deep adsorbent desulfurizing and denitrifying method, wherein, hydrocracking tail oil with a certain content of sulphide and nitride is contacted with a hydrocracking tail oil ultra-deep adsorbent desulfurizing and denitrifying absorbent at certain temperature, pressure and airspeed, thereby obtaining desulfurized and denitrified hydrocracking tail oil which is absorbed and refined. The refined hydrocracking tail oil has a sulfur content lower than 10mug.g<-1> and a nitrogen content lower than 2mug.g<-1>, which satisfies requirements of hydroisomerized dewaxing material. The hydrocracking tail oil ultra-deep adsorbent desulfurizing and denitrifying method employs tower-type continuous operation of fixe bed, the process is simple and easy to realize, thereby overcoming disadvantages of the prior art that mixing and separating of liquid denitrifier and oil product is difficult, desulfurizing and denitrifying depths are insufficient, and operation is complex. Therefore, the method is especially applicable to ultra-deep adsorbent desulfurizing and denitrifying of hydrocracking tail oil.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Catalyst used for coal tar pitch hydrocracking lightening reaction

InactiveCN102029157AEasy to makeLow costMolecular sieve catalystsHydrocarbon oil crackingPtru catalystMetallic sulfide

The invention relates to a catalyst used for coal tar pitch hydrocracking lightening reaction. The preparation method of the catalyst comprises the following steps: taking an inorganic porous material as a carrier; selecting at least one of alumina, silica gel containing alumina, MCM-41 (mobile crystalline material-41) and SBA-15 (santa barbara amorphous-15); loading one or two of metal elements Fe, Ni, Co and Mo of active components onto the carrier in the form of metallic oxide or metallic sulphide by adopting a vacuum immersion method, wherein the metallic oxide or metallic sulphide content of the active components is 1-20wt% of the catalyst; then drying for 1-14 hours under the conditions that nitrogen is used for protection, normal pressure is kept and the temperature is 70-120 DEG C; and then roasting at the temperature of 500 DEG C for 3 hours. The catalyst in the invention has the advantages of simple preparation process, high catalytic activity, less reaction coking and high cracked light oil yield, thus being especially applicable to hydrocracking lightening of heavy component and pitch in coal tar, and the catalyst in the invention can cause conversion per pass of coal bar pitch to reach more than 70%.

Owner:TONGJI UNIV

Solution and method for scavenging sulphur compounds

There is disclosed herein a solution for removing a sulphur compound or carbon dioxide from a fluid and methods for its use, said solution comprising sulphuric acid, a metal at between about 0.05 to 10 percent by weight, an amine at between about 10 to 80 percent by volume and water. In one aspect, the sulphuric acid is in the form of a chelating agent and in another it is in the form of a derivative of a sulphur-based acidic compound. The sulphur compound may be hydrogen sulphide, carbonyl sulphide or a mercaptan. In one aspect, the method is practiced at temperatures significantly below zero. In another aspect, this invention is an acid / amine solution comprising sulphuric acid, sulphuric acid in the form of a chelating agent, or a.-derivative of a sulphur-based acidic compound and monoethanolamine. This solution may be used as a source of monoethanolamine.

Owner:CFR PATENTS INC

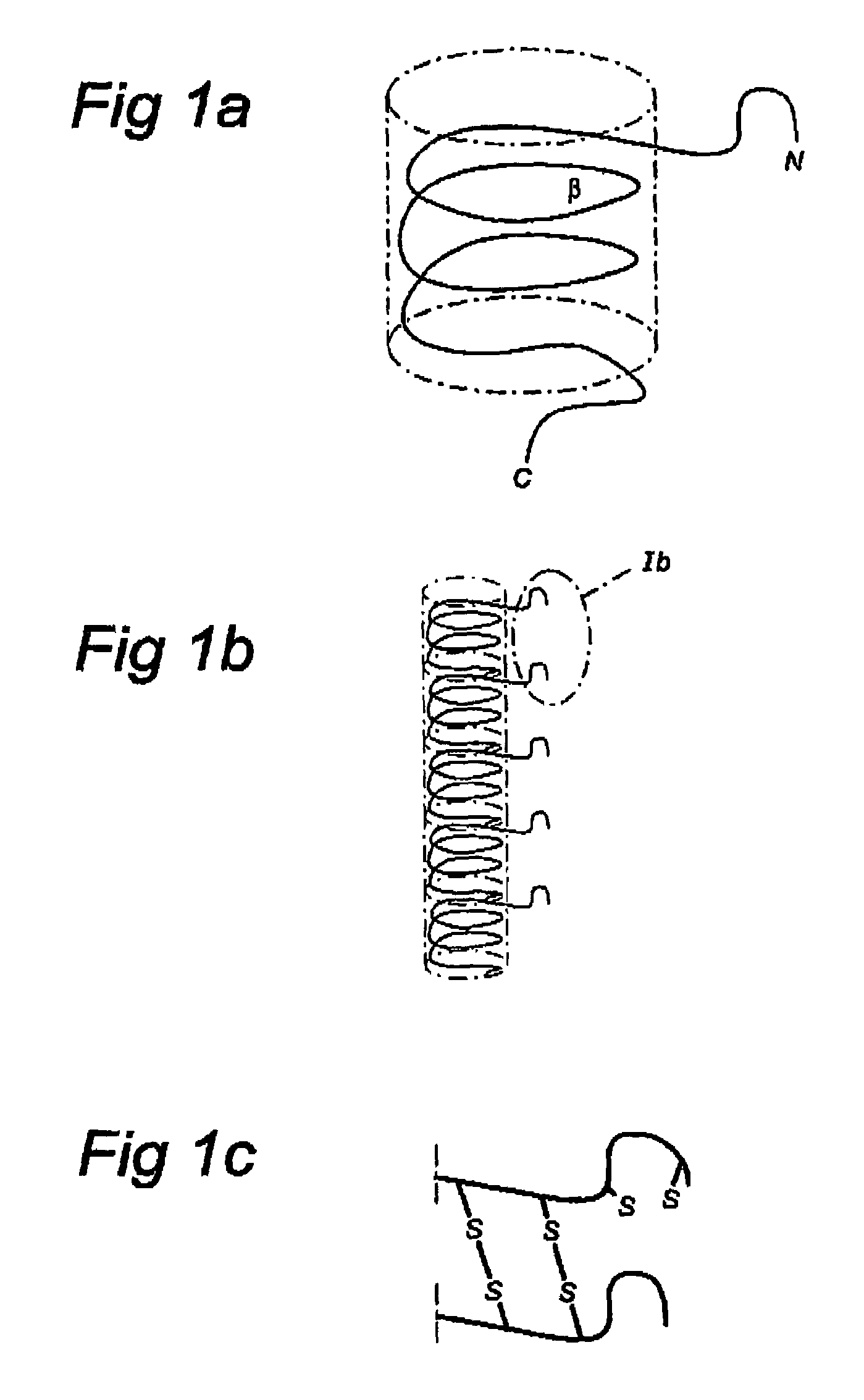

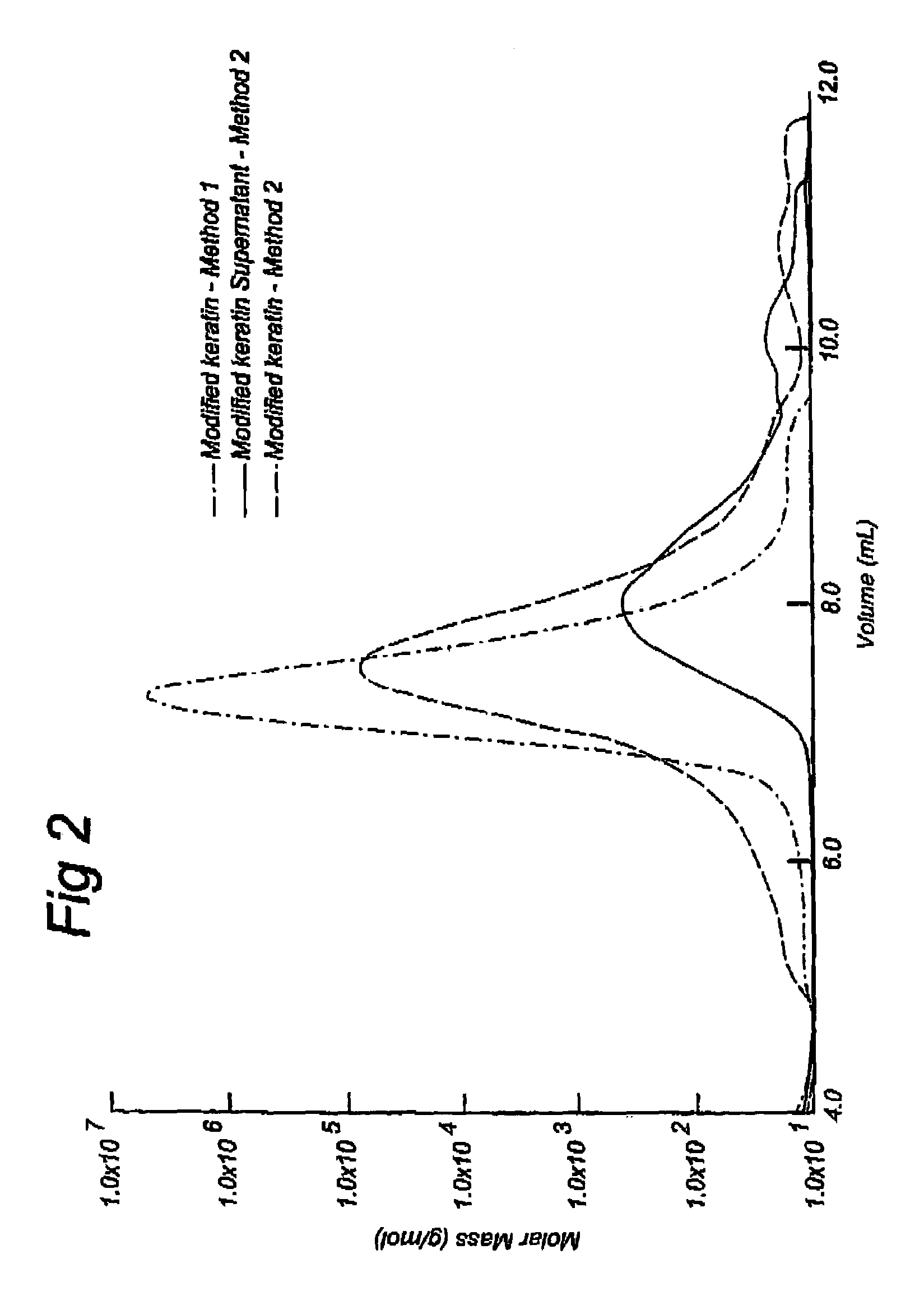

Keratin-based products and methods for their productions

InactiveUS7169896B2Good dispersionImprove adhesionCosmetic preparationsConnective tissue peptidesCysteine thiolateSulfide

The present invention relates to a process for solubilizing keratins from a keratin containing starting material such as poultry feathers. The keratins are may be solubilized using a sulphide under alkaline conditions. In the process the cysteine residues of solubilized keratins and are partially modified, e.g. by alkylation. The conditions of solubilisation and partial modification are chosen such that the keratins are also partially hydrolyzed. The partially modified and partially hydrolyzed keratin may be used as stable dispersions e.g. for the production of films and coatings by casting.

Owner:STICHTING NEDERLANDS INST VOOR ZUIVELONDERZOEK (NIZO)

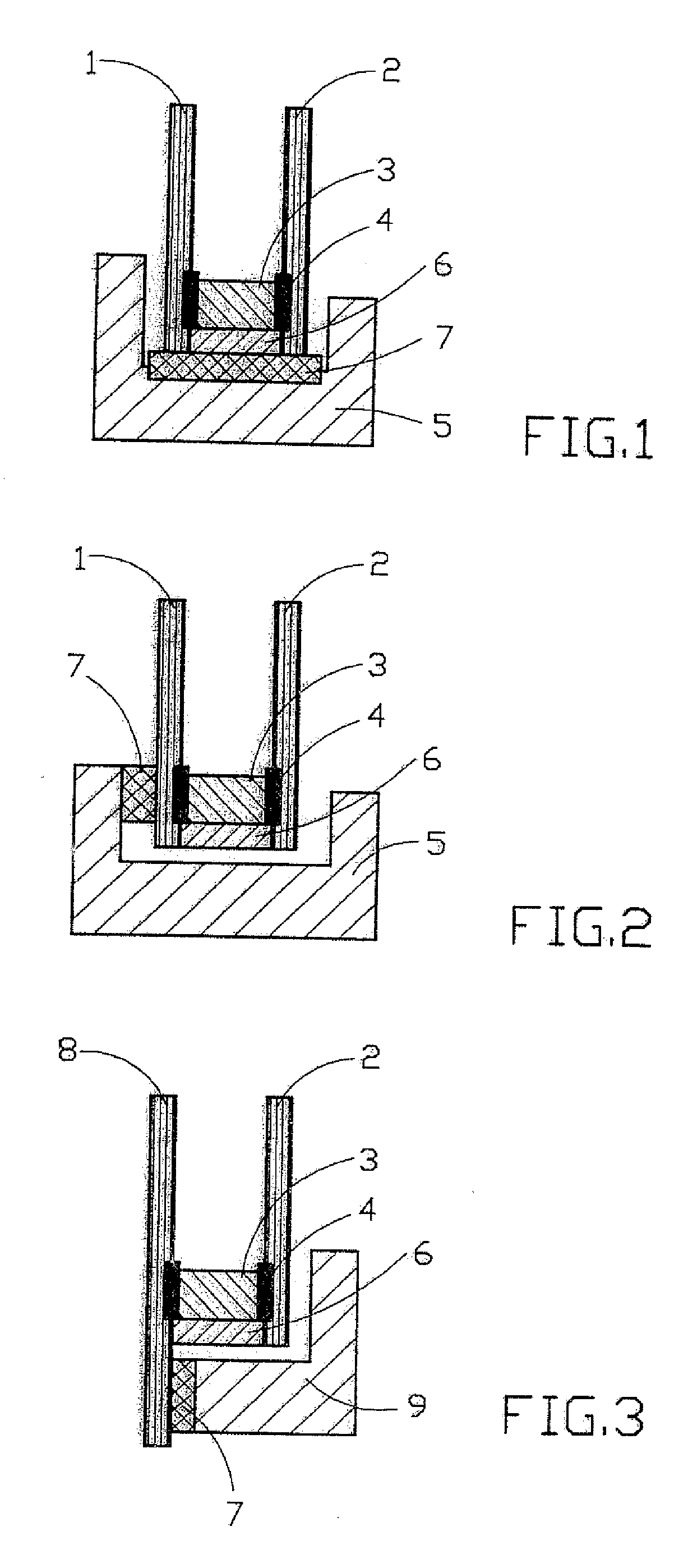

Use of Polysulphide- Containing Two- Component Adhesives for the Production of Windows

A polysulphide-containing two-component adhesive / sealant consists of a binder component and a curing agent component, and is suitable for use as the secondary seal in the edge region of the insulating glass and / or for bonding the insulating glass unit in the frame or window sash of a window unit in a friction locked manner according to the process of rebate base bonding or back bedding.

Owner:HB FULLER CO

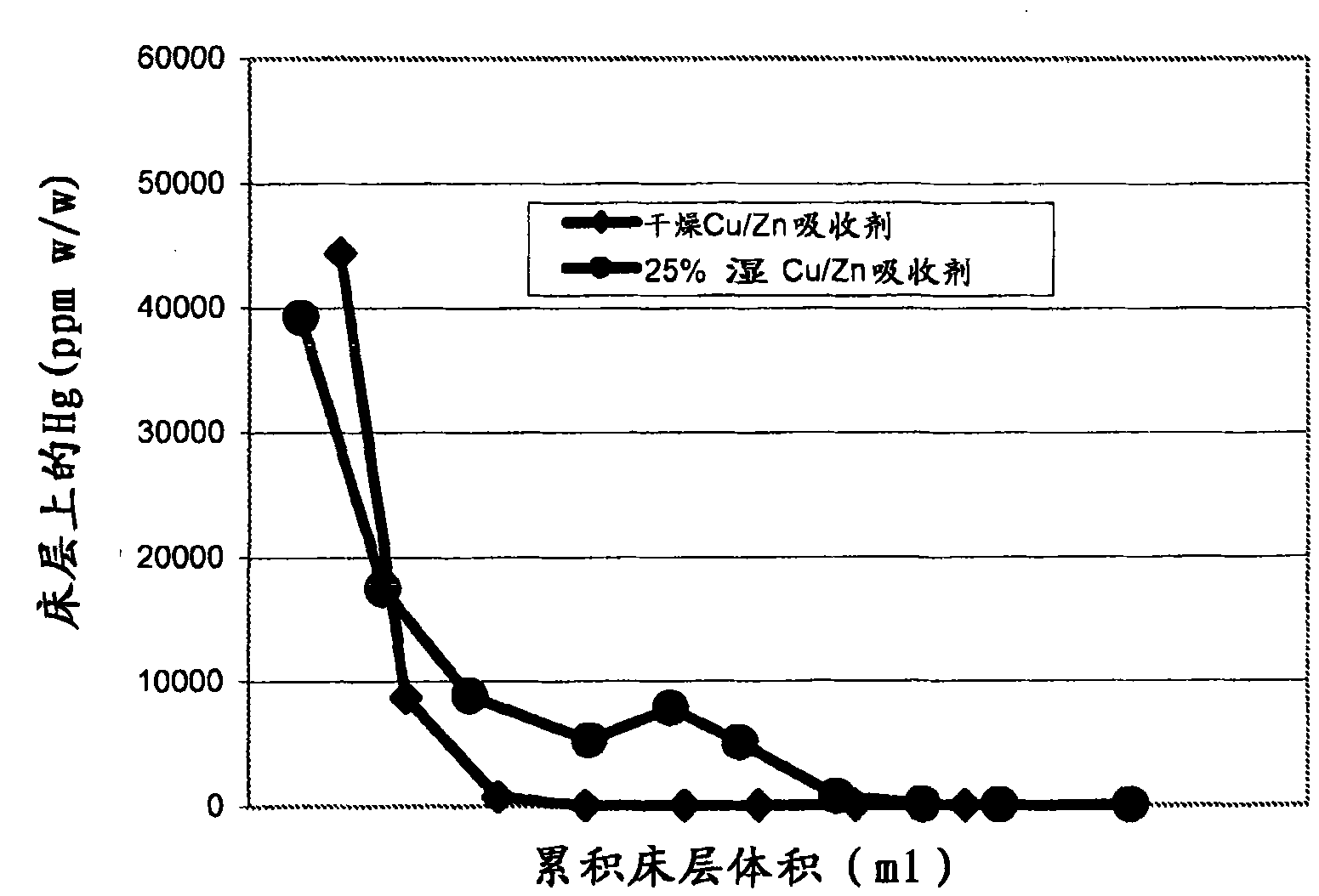

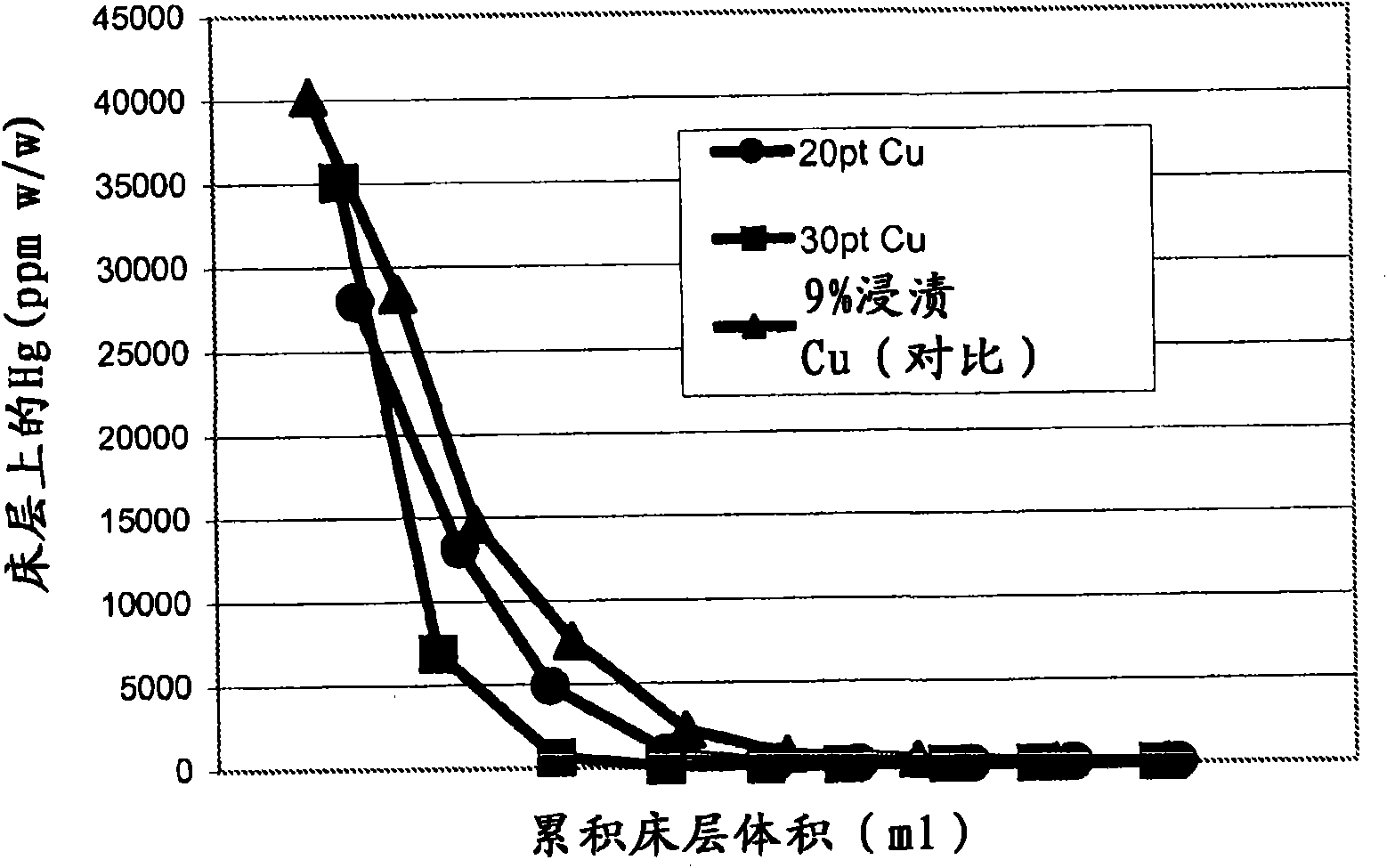

Absorbent

ActiveCN101945700AAvoid volumeAvoid intensityOther chemical processesSeparation devicesParticulatesMetallic sulfide

An absorbent composition suitable for removing mercury, arsenic or antimony from fluid streams is described, comprising 5-50% by weight of a particulate sulphidedcopper compound, 30-90% by weight of a particulate support material, and the remainder one or more binders, wherein the metal sulphide content of the absorbent, other than copper sulphide, is below 5% by weight.

Owner:JOHNSON MATTHEY PLC

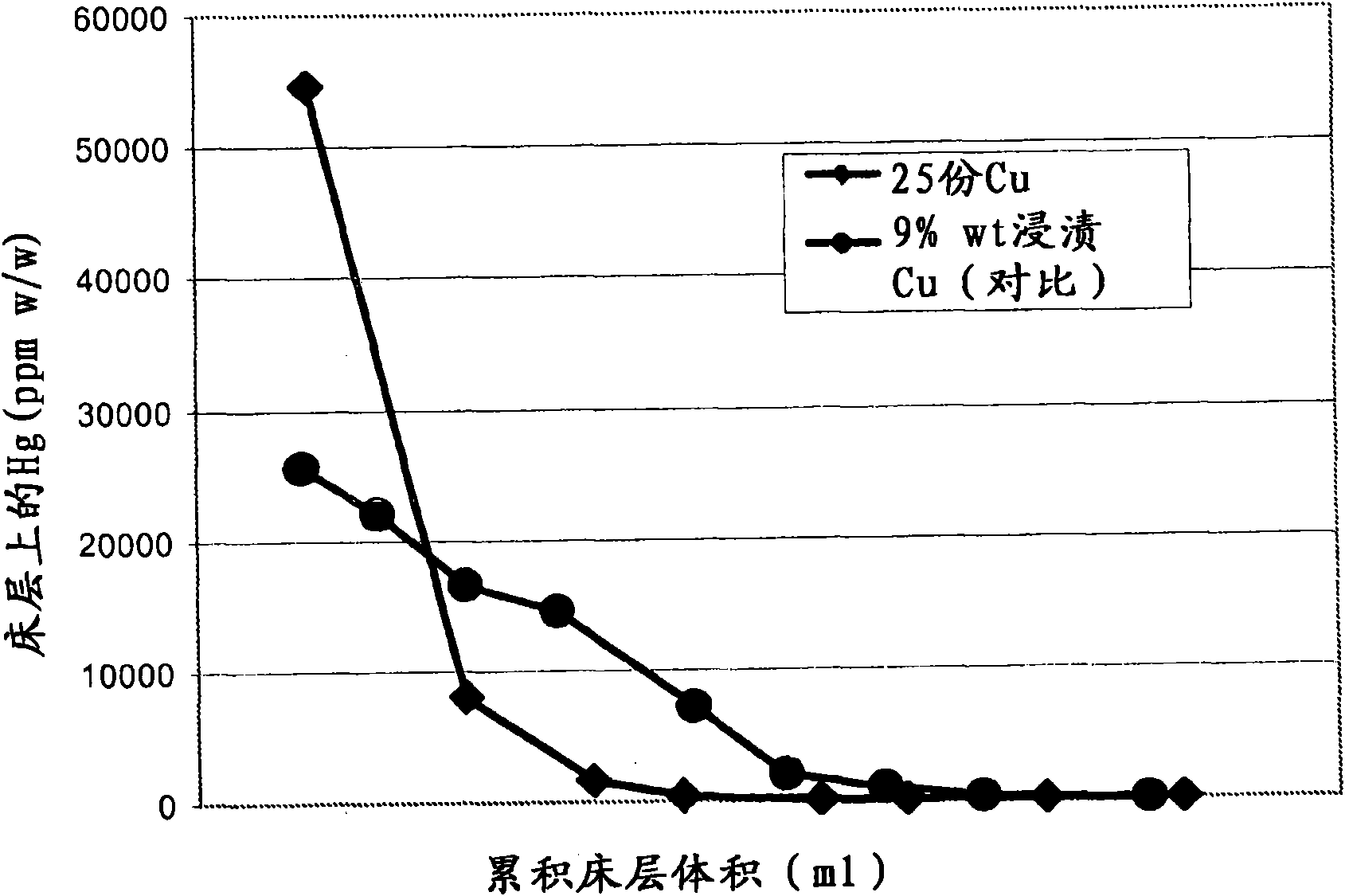

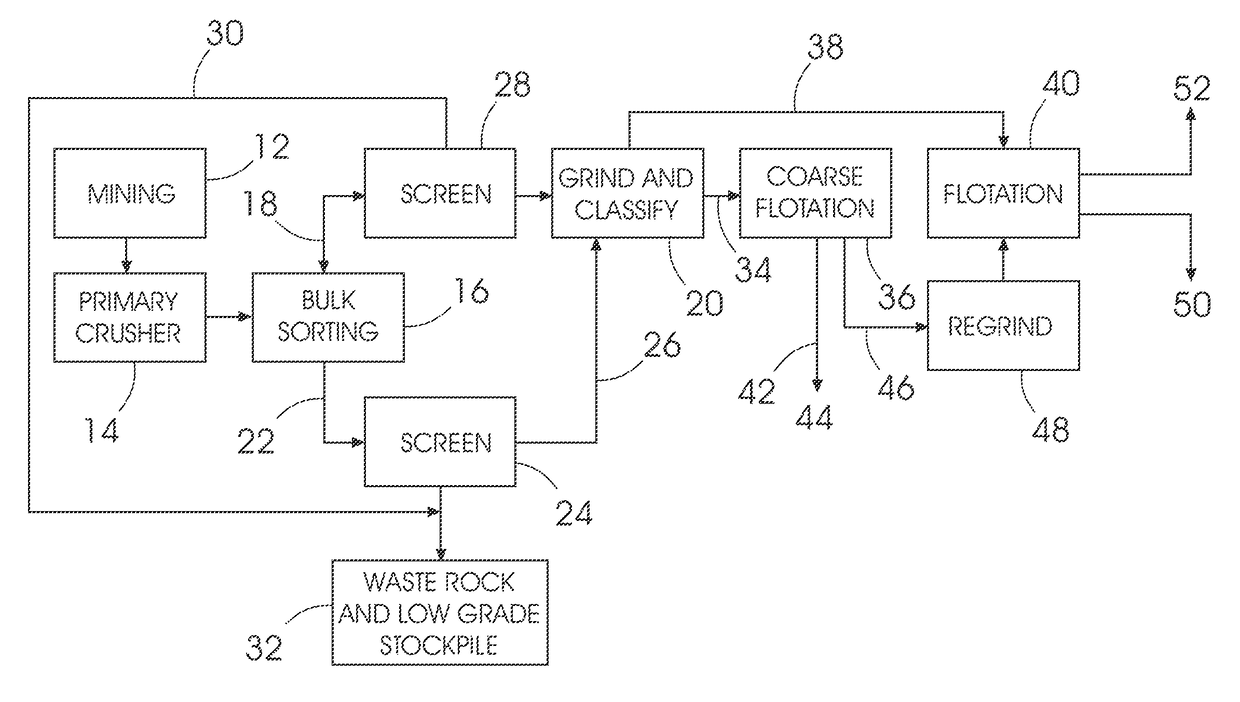

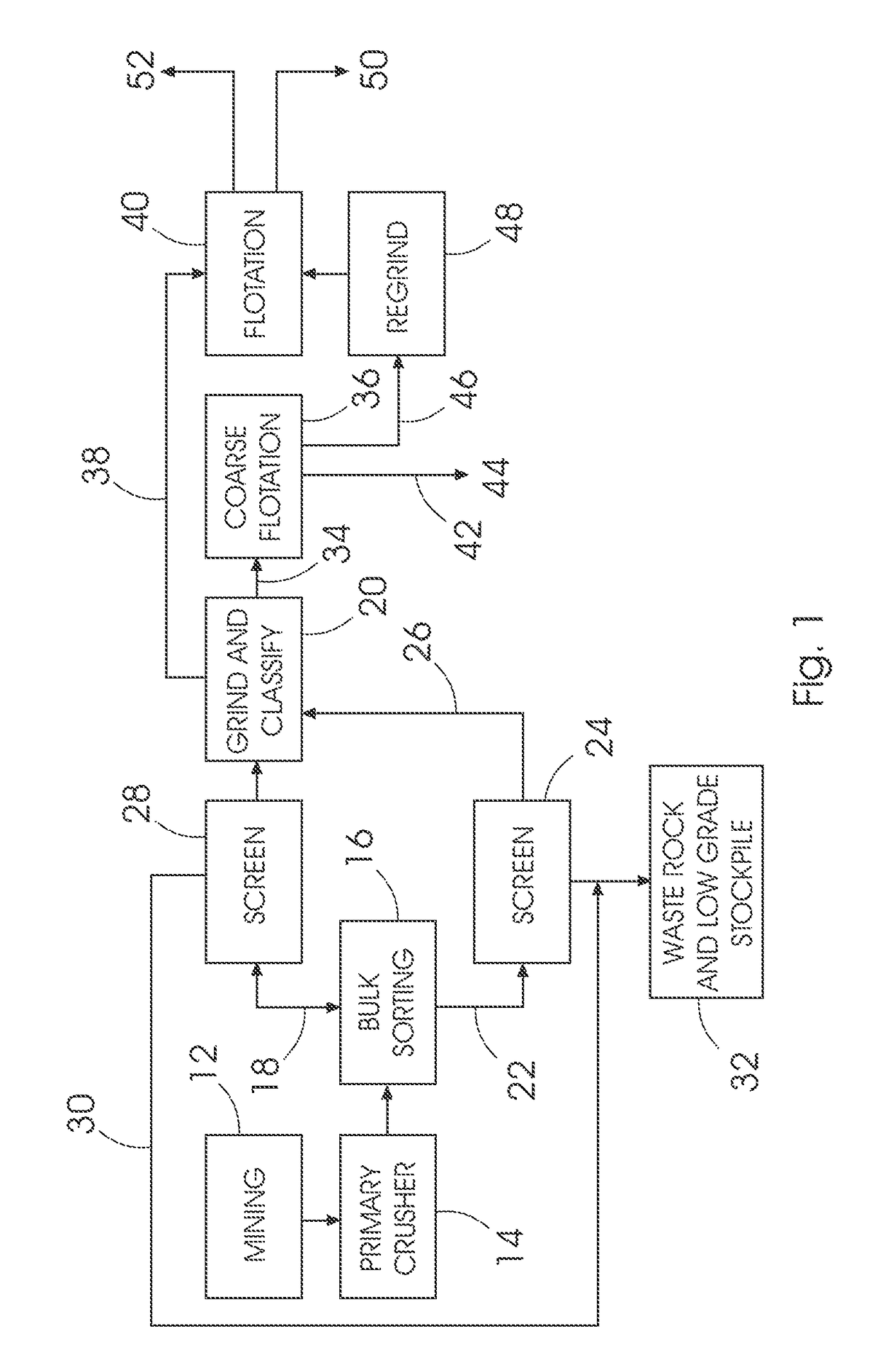

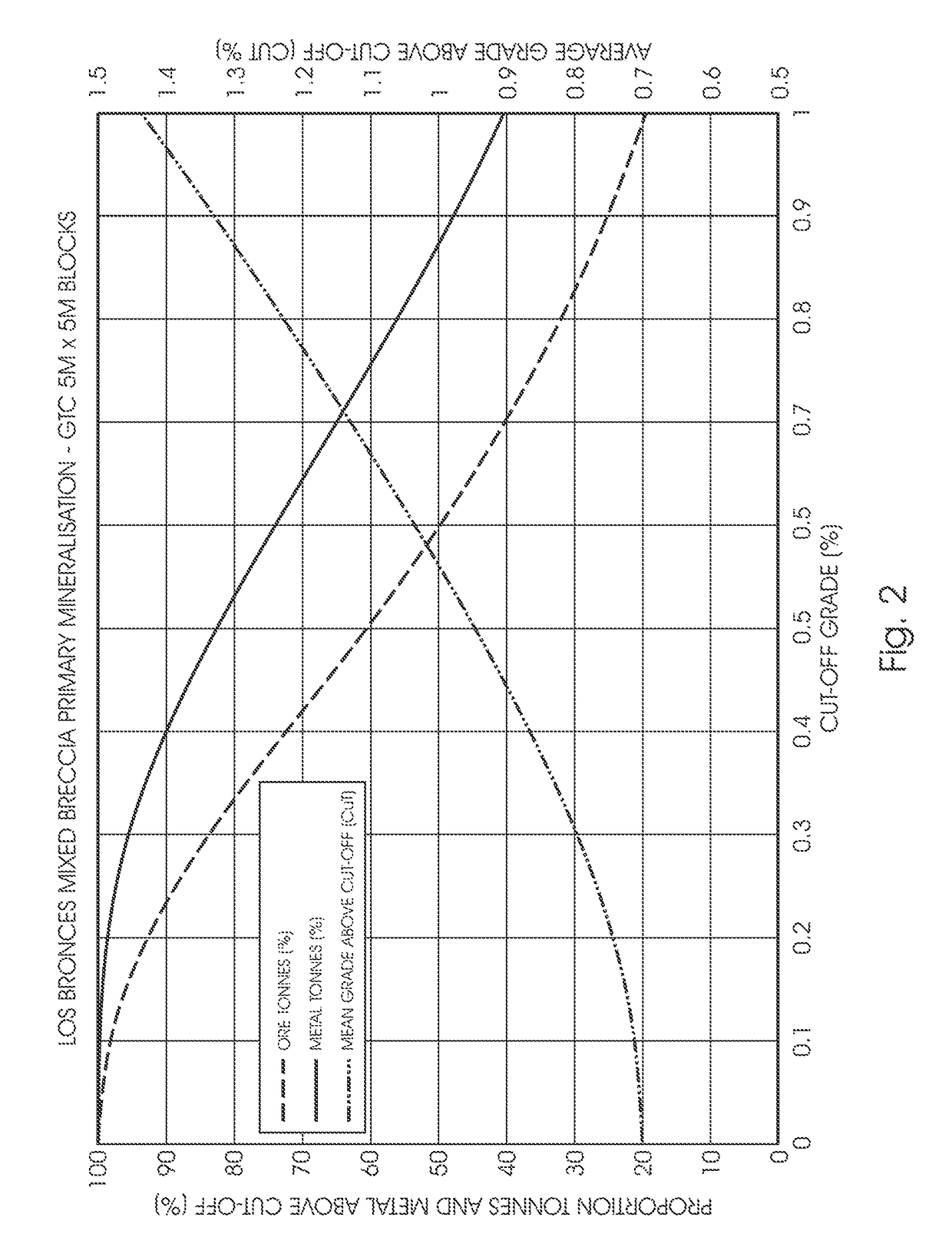

Maximise the value of a sulphide ore resource through sequential waste rejection

This invention relates to an integrated process for recovering value metals from sulphide ore which includes the steps of bulk sorting 16 and screening 24 / 28 crushed ore. The sorted / screened coarse ore stream is ground and classified 20 to provide a coarse fraction 34 suitable for coarse flotation and a first fine fraction 38 suitable for flotation. The coarse fraction suitable for coarse flotation is subjected to coarse flotation 36 thereby to obtain a gangue 42 and an intermediate concentrate 46. The intermediate concentrate is subjected to grinding 48 to provide a second fine fraction suitable for conventional flotation. The first fine fraction and the second fine fraction are subjected to conventional flotation 40 to provide a concentrate and tailings. This process that capitalizes on the natural heterogeneity of sulphide orebodies, and utilizes bulk sorting, screening and coarse flotation beneficiation technologies in a novel multistage configuration to reject the maximum quantity of waste gangue prior to fine comminution.

Owner:ANGLO AMERICAN TECH & SUSTAINABILITY SERVICES LTD

Two-phase stainless steel alloy and preparation method thereof

The invention discloses a two-phase stainless steel alloy and a preparation method thereof. The two-phase stainless steel alloy is composed of the following chemical components in percentage by mass: 0.01-0.03 percent of C, 0.1-2.0 percent of Si, 1.0-3.0 percent of Mn, 20-22 percent of Cr, 1.7-2.5 percent of Ni, 0.7-1.0 percent of Cu, 0.1-0.2 percent of N, 0.2-1.0 percent of W, as well as Fe and unavoidable impurity elements in balancing amount. According to the invention, the two-phase stainless steel has good performance of mechanics, hot working performance and high corrosion resistance, and can be manufactured by the prior art. The adopted low-cost N and Mn substitute Ni to stabilize the Austenite phase of the two-phase stainless steel, and the low-cost W substitutes Mo, so that the cost is lowered; and meanwhile, the lower content of the element M is controlled via reasonably regulating the mixture ratio of the elements Ni, N and Mn, a situation that low-melting-point sulphides exist at a phase boundary is avoided, and the hot working performance of the two-phase stainless steel is effectively ameliorated.

Owner:ZHEJIANG UNIV +1

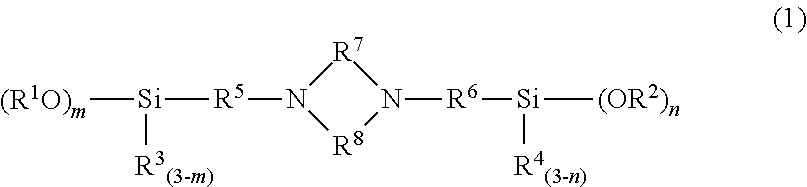

Method for Producing Modified Conjugated Diene-Based Polymer, Modified Conjugated Diene-Based Polymer, and Modified Conjugated Diene-Based Polymer Composition

ActiveUS20120277369A1Solve the lack of resistanceHigh strengthSpecial tyresAlkaline earth metalPolymer chemistry

There are provided a modified conjugated diene-based polymer having a good balance between the hysteresis loss properties and the wet skid resistance, practically sufficient abrasion resistance and fracture strength, and high processability when formed into a vulcanized product, and a modified conjugated diene-based polymer composition. A method for producing a modified conjugated diene-based polymer, comprising: a polymerization step of polymerizing a conjugated diene compound or copolymerizing a conjugated diene compound with an aromatic vinyl compound using an alkali metal compound or an alkaline earth metal compound as a polymerization initiator to obtain a conjugated diene-based polymer having a reactive end, and a modifying step of reacting a compound having a specific structure with the reactive end of the conjugated diene-based polymer.

Owner:ASAHI KASEI CHEM CORP

Method to obtain a corrosion-resistant and shiny substrate

InactiveCN101370961AExtend working lifeImprove visual appearanceVacuum evaporation coatingSputtering coatingBorideMetal alloy

The present invention relates to a process for producing a metallic and / or nonmetallic substrate which is protected against corrosion at least in regions and is, in particular, shiny, which comprises a) provision of a substrate having at least one surface which can be coated at least in regions and b) application of at least one metallic protective layer comprising a first metal, a first noble metal or a first metal alloy and at least one acid, an oxide, double oxide, hydrated oxide, sulphide, halide, nitride, carbide, carbonitride, boride, silicide, oxyhalide and / or salt of a second metal, of a second noble metal and / or of a second metal alloy. The invention further relates to a substrate which is protected against corrosion at least in regions and is, in particular, shiny, which comprises a substrate and at least one metallic protective layer comprising a first metal, a first noble metal or a first metal alloy and at least one acid, an oxide, double oxide, hydrated oxide, sulphide, halide, nitride, carbide, carbonitride, boride, silicide, oxyhalide, in particular oxyfluoride, and / or salt of a second metal, of a second noble metal and / or of a second metal alloy.

Owner:ROPAL EURO

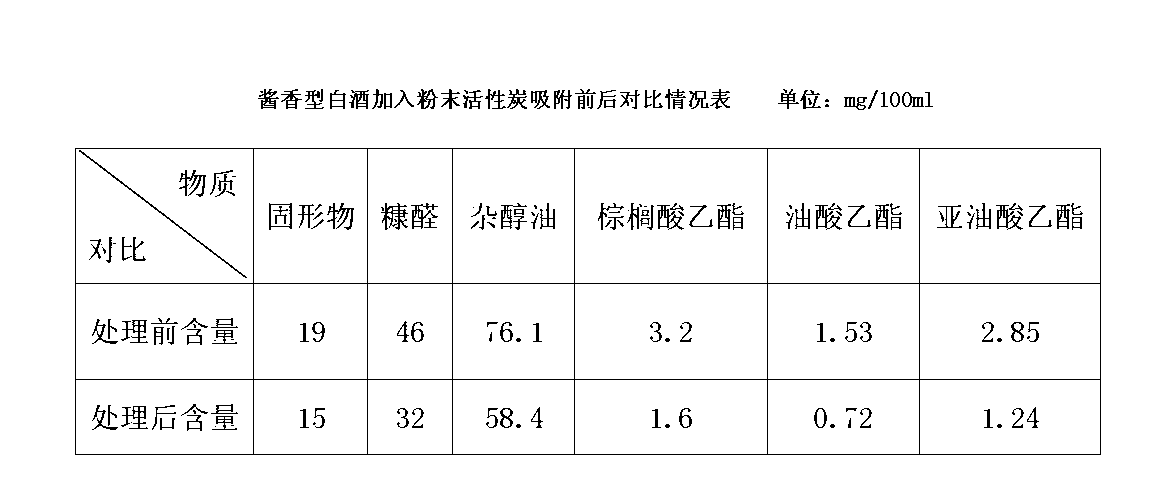

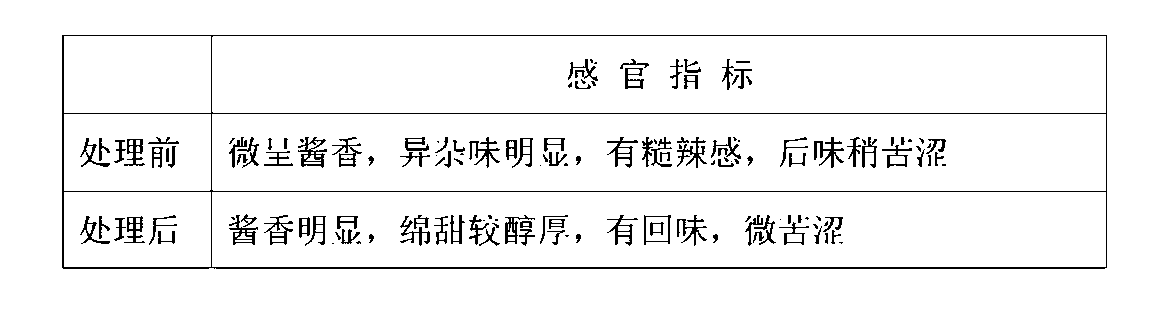

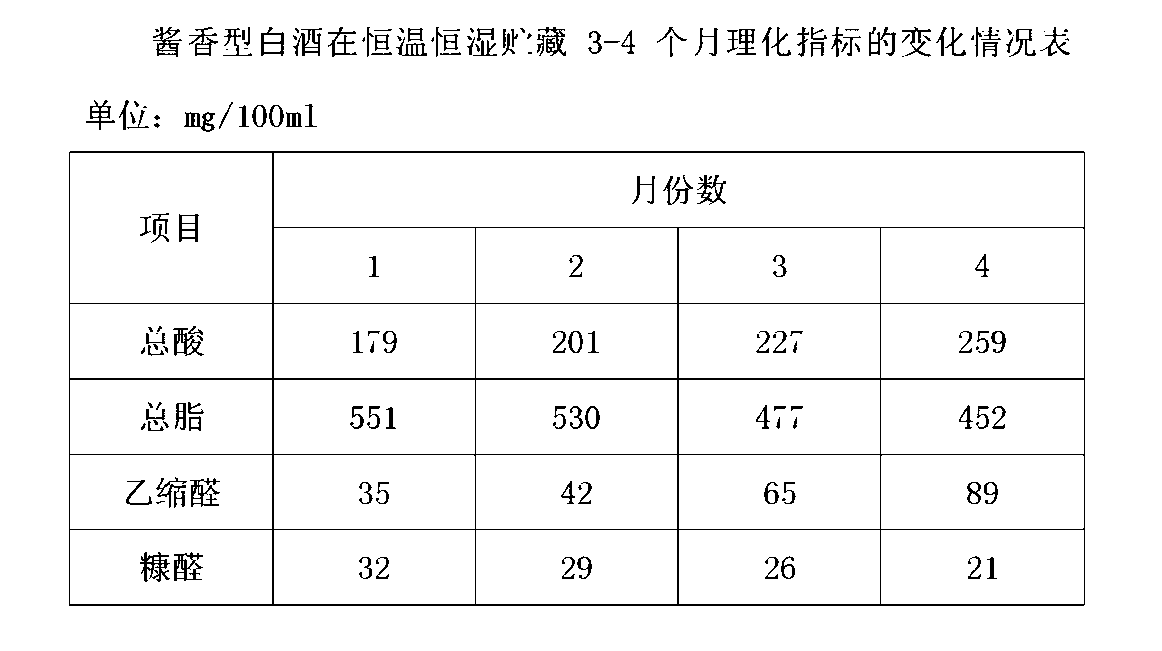

Maotai-flavour liquor treatment method

InactiveCN103131618AOperation mellowFull operationAlcoholic beverage preparationActivated carbonAcrolein

Owner:GUBEICHUN GROUP

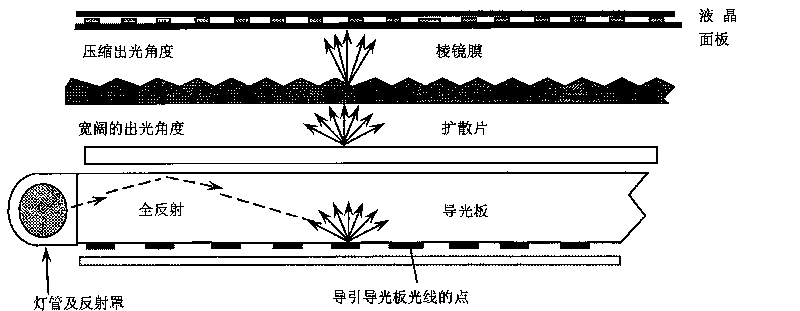

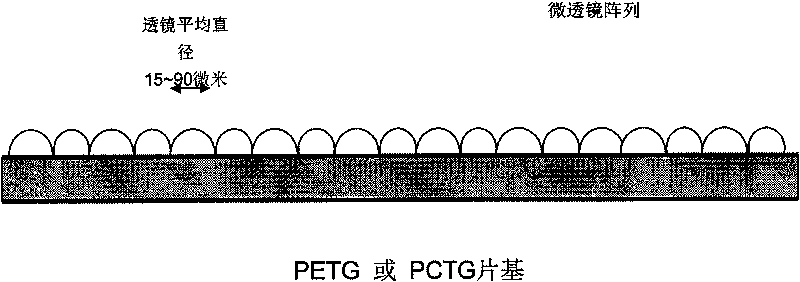

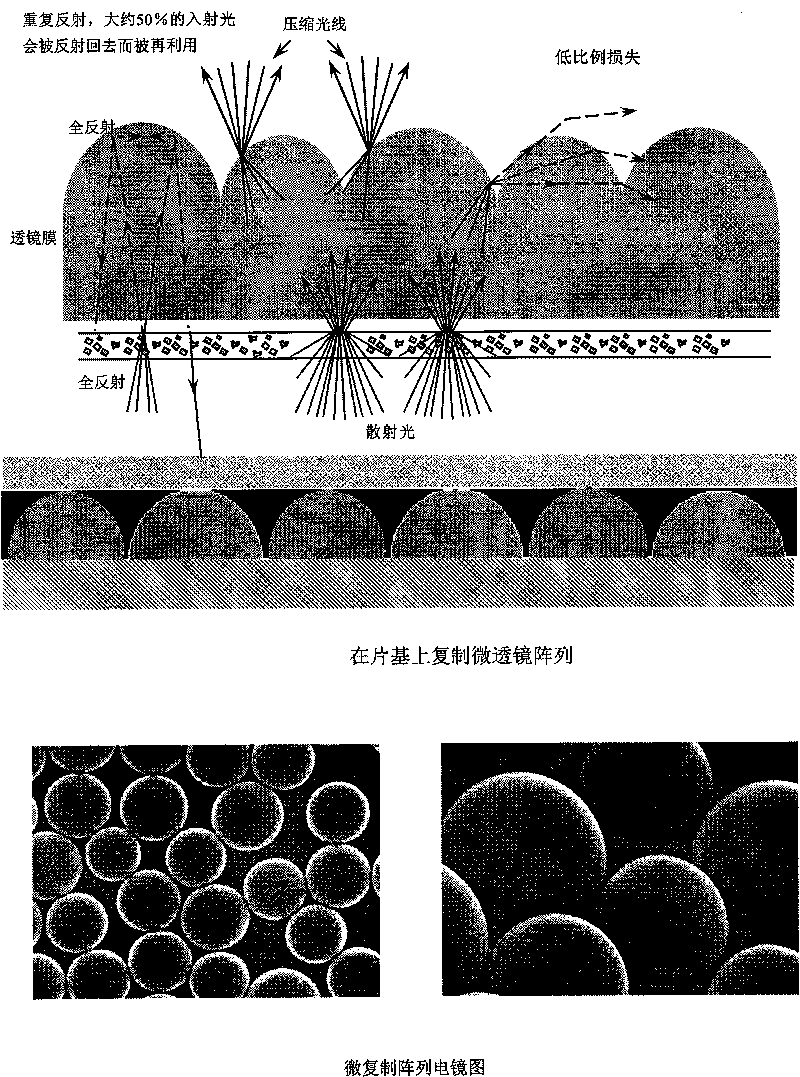

Duplicated array brightness enhancement film of large-viewing angle micro lens

The invention discloses duplication of array brightness enhancement film by a large-viewing angle micro lens and a production method of a duplicating mould. The invention continuously duplicates micro lens array on a film base without birefraction using halogen free and sulphide free resin containing nano particle. On all directions of a horizontal projection, the micro lens array has the function of gathering and condensing view angle to ordinary light or vibration light through utilizing the refraction and reflection of light from high refraction medium to low refraction medium, and the axial brightness can be improved in a larger range of viewing angle. Through using novel hair metal casting technology, the invention provides a mould which can continuously duplicate micro lens array. The invention is used in backlight source module of a liquid crystal display.

Owner:邹竞 +2

Process for preparing microporous crystalline titanium silicate

InactiveUS20040024075A1Highly cost-effectiveHigh mechanical strengthPigmenting treatmentAluminium compoundsAlcoholTitanium

A process for the preparation of crystalline microporous titanium silicates using ethylsilicate-40 and titanium peroxide as silicon and titanium sources respectively is described. The process permits a significant decrease in the production cost of titanium silicate containing higher amount of titanium (Si / Ti=20) because of cheaper raw materials as well as reduction in the quantity of tetarpropylammonium hydroxide (TPAOH) template (SiO2:TPAOH=1:0.06-0.1) required for preparation. The material obtained by the present invention is useful as an active catalyst in the reactions such as oxidation of hydrocarbons, alcohols, sulphides, and thioethers.

Owner:COUNCIL OF SCI & IND RES

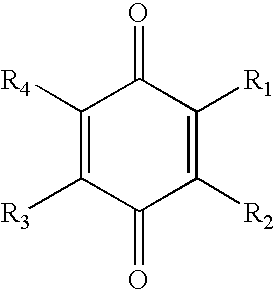

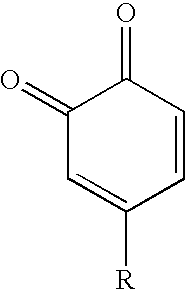

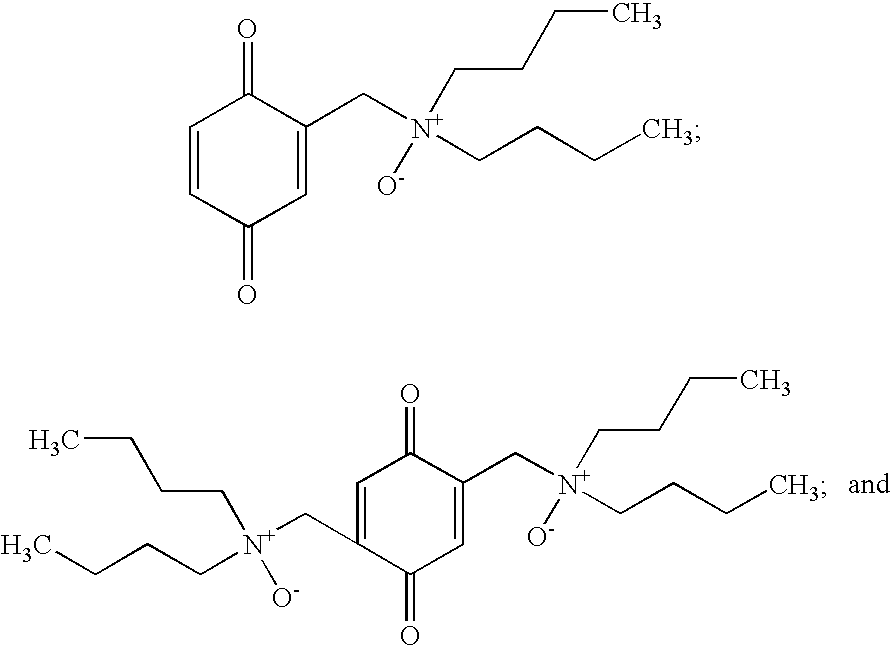

Multifunctional scavenger for hydrocarbon fluids

Compounds having the formulae and general formulae:wherein each R1, R2, R3 and R4 are the same or different and may be hydrogen, an alkyl group, an aryl group, a halogen, a nitro group, an alkyl or aryl ester, and an alkyl or aryl ether;compounds having the general formula:wherein R is an alkyl, aryl or electron withdrawing group;mixtures thereof; can be used as additives for crude oil and hydrocarbons. These compounds may be used to scavenge mercaptans, sulfides, cyanides, and primary or secondary amines; either alone or in combination.

Owner:BAKER HUGHES INC

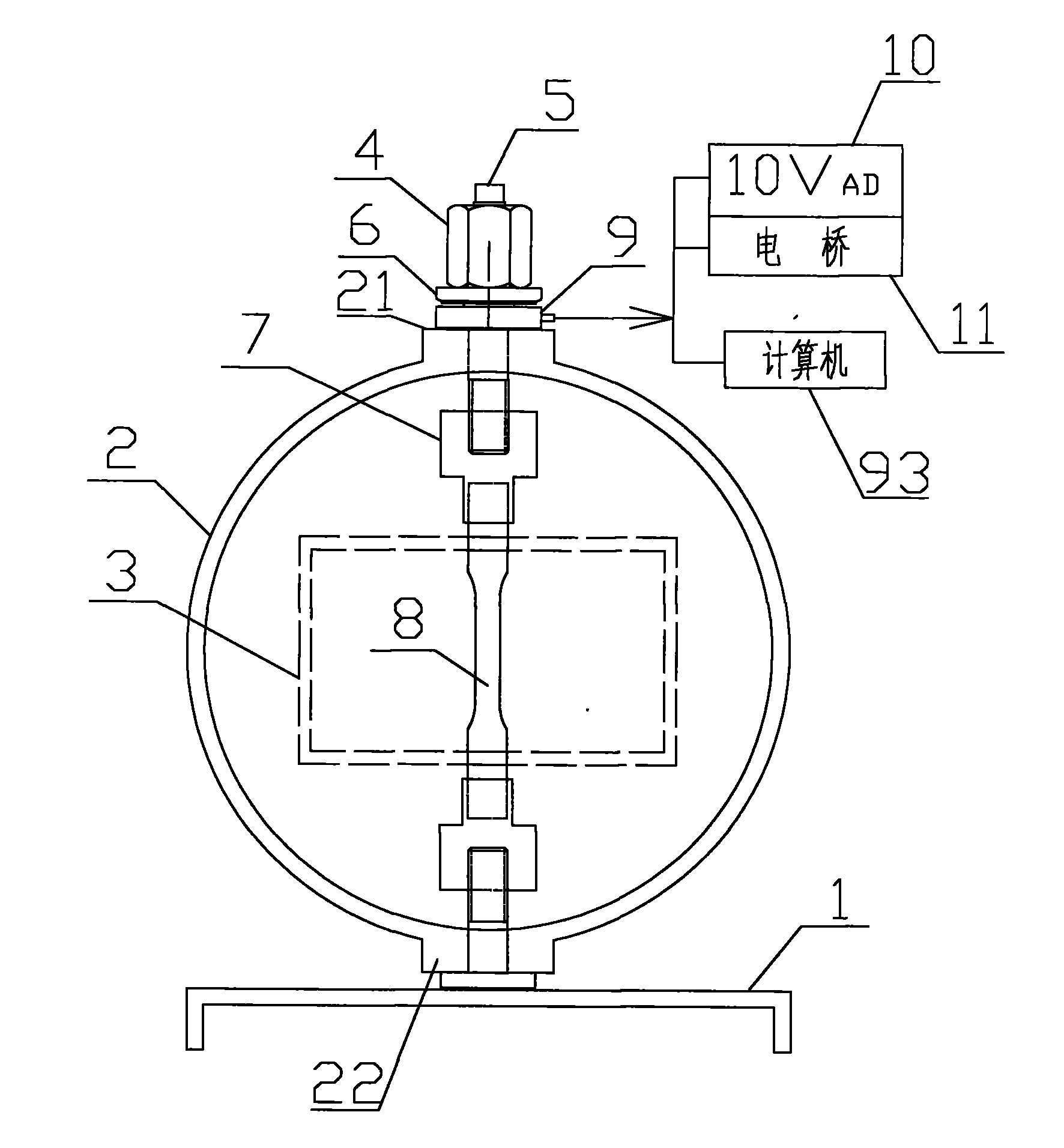

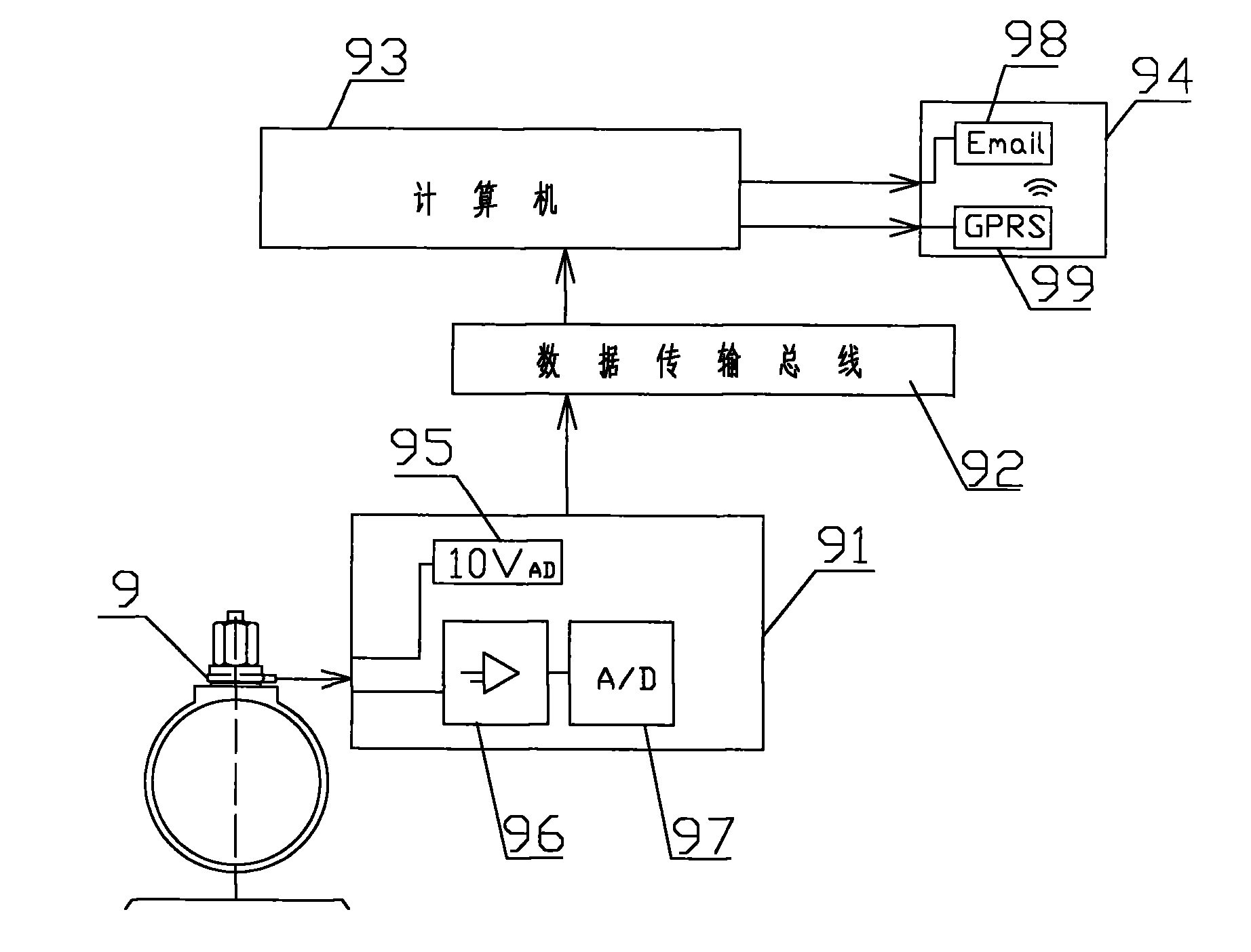

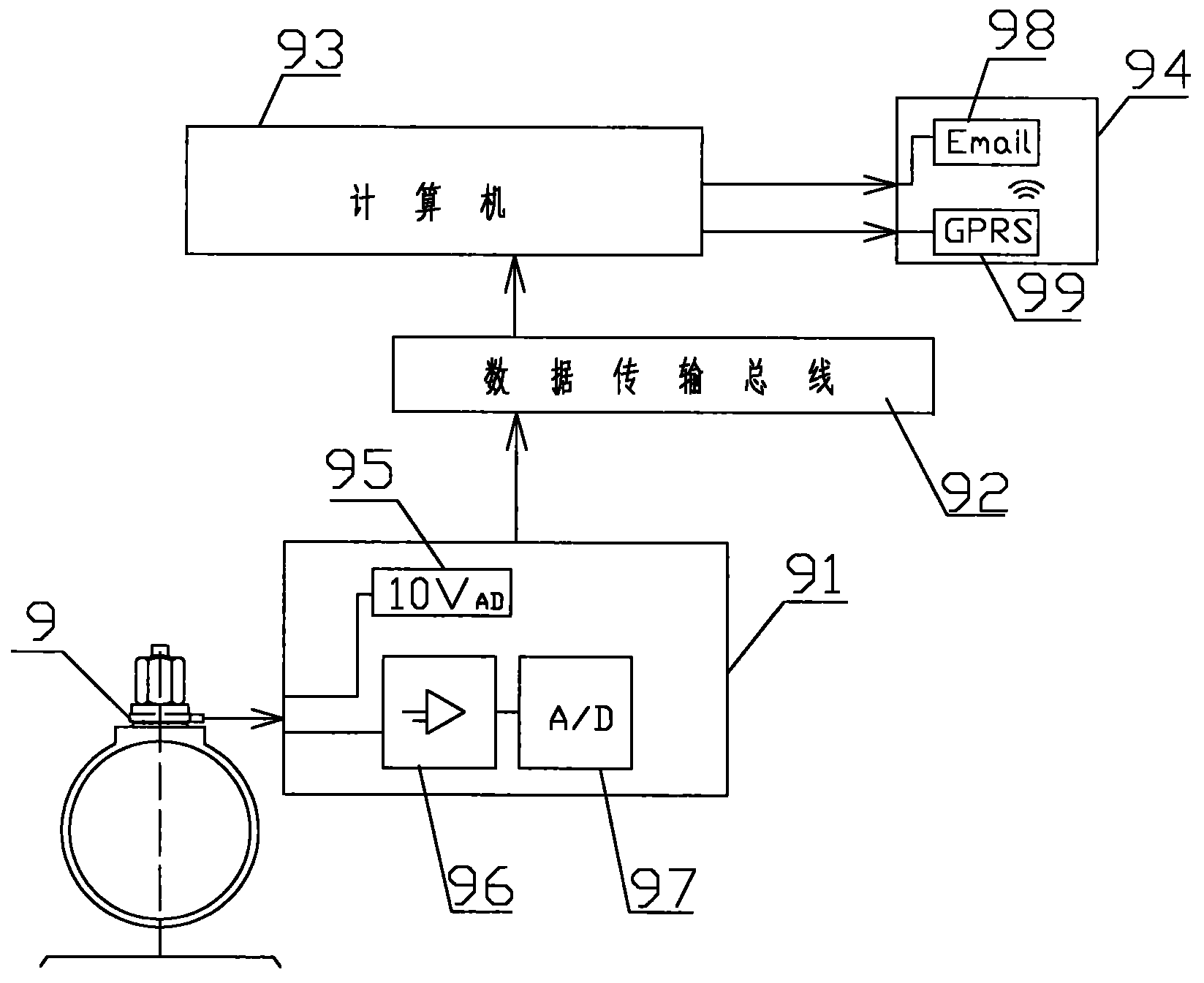

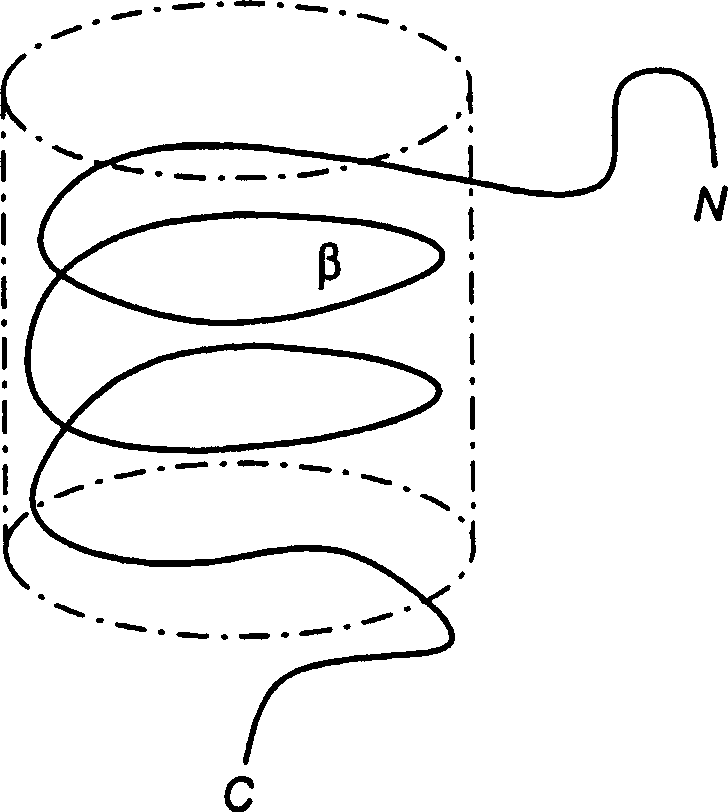

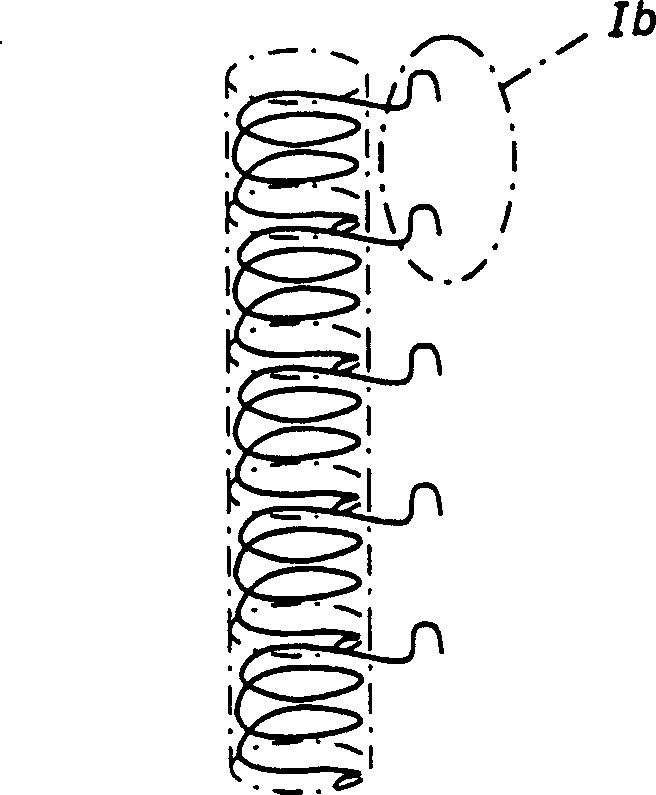

Sulphide stress corrosion uniaxial tensile test loading detection method and monitoring system thereof

ActiveCN101988879AGuaranteed accuracyForce measurementMaterial strength using tensile/compressive forcesData operationsMonitoring system

The invention discloses a sulphide stress corrosion uniaxial tensile test loading detection method and a monitoring system thereof. The method includes that an annular load sensor is added between a thrust bearing below a loading nut of stress corrosion tensile test equipment and a platform on a stress ring, and the sensor directly detects a load applied by tensile test; and the monitoring system adopts a load information acquisition module to acquire the output information of the load sensor, the load information acquisition module inputs the acquired information to a computer by virtue of data transmission bus, the computer carries out data storage, data operation and test condition monitoring on the information, and test condition information is input to a information notification module, and meanwhile the information notification module sends a information notice by virtue of an electronic mail assembly and a GPRS assembly. The invention can accurately detect the load applied by test online, and accuracy of test is ensured; and the monitoring system monitors the test process online, monitors the test condition, processes test data in real time and timely gives notification.

Owner:SHANGHAI HILONG DRILL PIPE MATERIALS INST +2

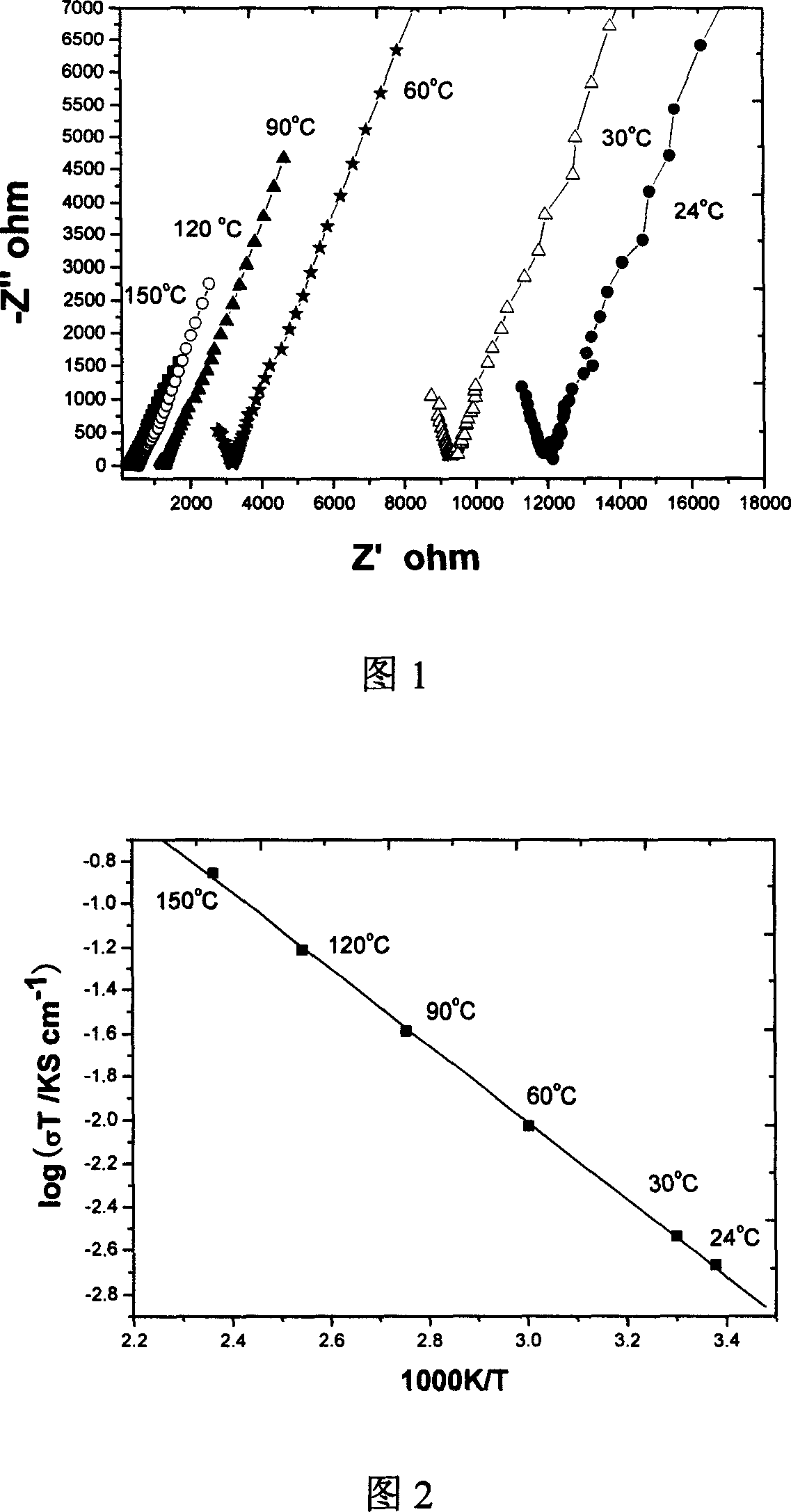

Visible light responding selenium-doped sulphide photocatalyst and preparation method thereof

InactiveCN101947462AWater/sewage treatment by irradiationDispersed particle separationChemical substanceWavelength range

The invention relates to a visible light responding sulphide photocatalyst and a preparation method thereof, belonging to the field of inorganic nano photocatalytic materials. The catalyst comprises selenium-doped nano-metal sulphide semi-conductors including zinc sulphide, cadmium sulphide and bismuthous sulphide. The photocatalyst has photocatalytic activity in wider wavelength range and can treat toxic and harmful chemical substances through photodecomposition and purification under radiation of ultraviolet light, visible light or natural light.

Owner:TIANJIN POLYTECHNIC UNIV

Keratin-based products and methods for their production

The present invention relates to a process for solubilising keratins from a keratin containing starting material such as poultry feathers. The keratins are may be solubilised using a sulphide under alkaline conditions. In the process the cysteine residues of solubilized keratins are partially modified, e.g. by alkylation. The conditions of solubilisation and partial modification are chosen such that the keratins are also partially hydrolysed. The partially modified and partially hydrolysed keratin may be used as stable dispersions e.g. for the production of films and coatings by casting.

Owner:STICHTING NEDERLANDS INST VOOR ZUIVELONDERZOEK (NIZO)

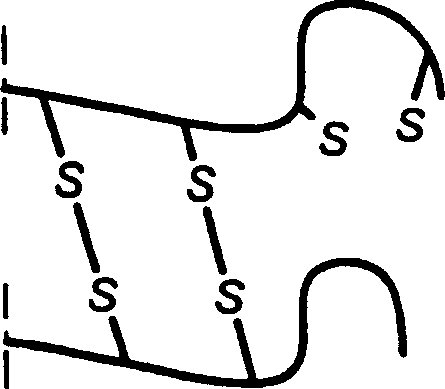

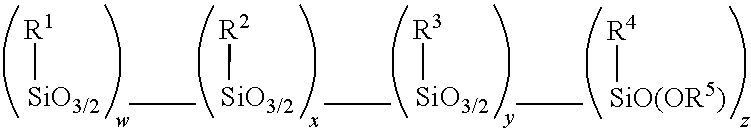

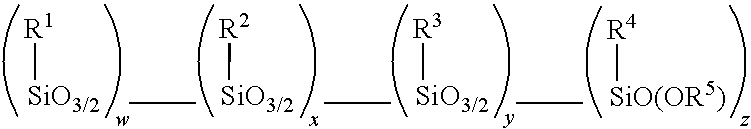

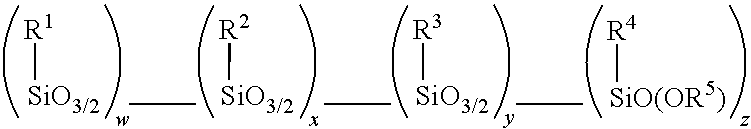

Amino alkoxy-modified silsesquioxane adhesives for improved metal adhesion and metal adhesion retention to cured rubber

Amino alkoxy-modified silsesquioxanes (amino AMS), and / or amino co-AMS compounds that also comprise a mercaptosilane or a blocked mercaptosilane, are excellent adhesives for coating plated or unplated metal wire for adherence of the wire to a rubber stock. The amino AMS and / or the amino / mercaptan co-AMS adhesives can be used with all types of rubber and there is no requirement for the use of special adhesive additives to the rubber vulcanizates, such as, but not limited to, cobalt, resins and high sulfur levels. In particular, the use of amino AMS and / or amino / mercaptan co-AMS compounds as adhesives for bonding wire to rubber also improves the adherence performance of the reinforcements to obtain sufficient bonding that is resistant to degradation over the course of time, especially resistance to thermal aging and / or thermo-oxidizing aging, in particular corrosion in the presence of water.

Owner:BRIDGESTONE CORP

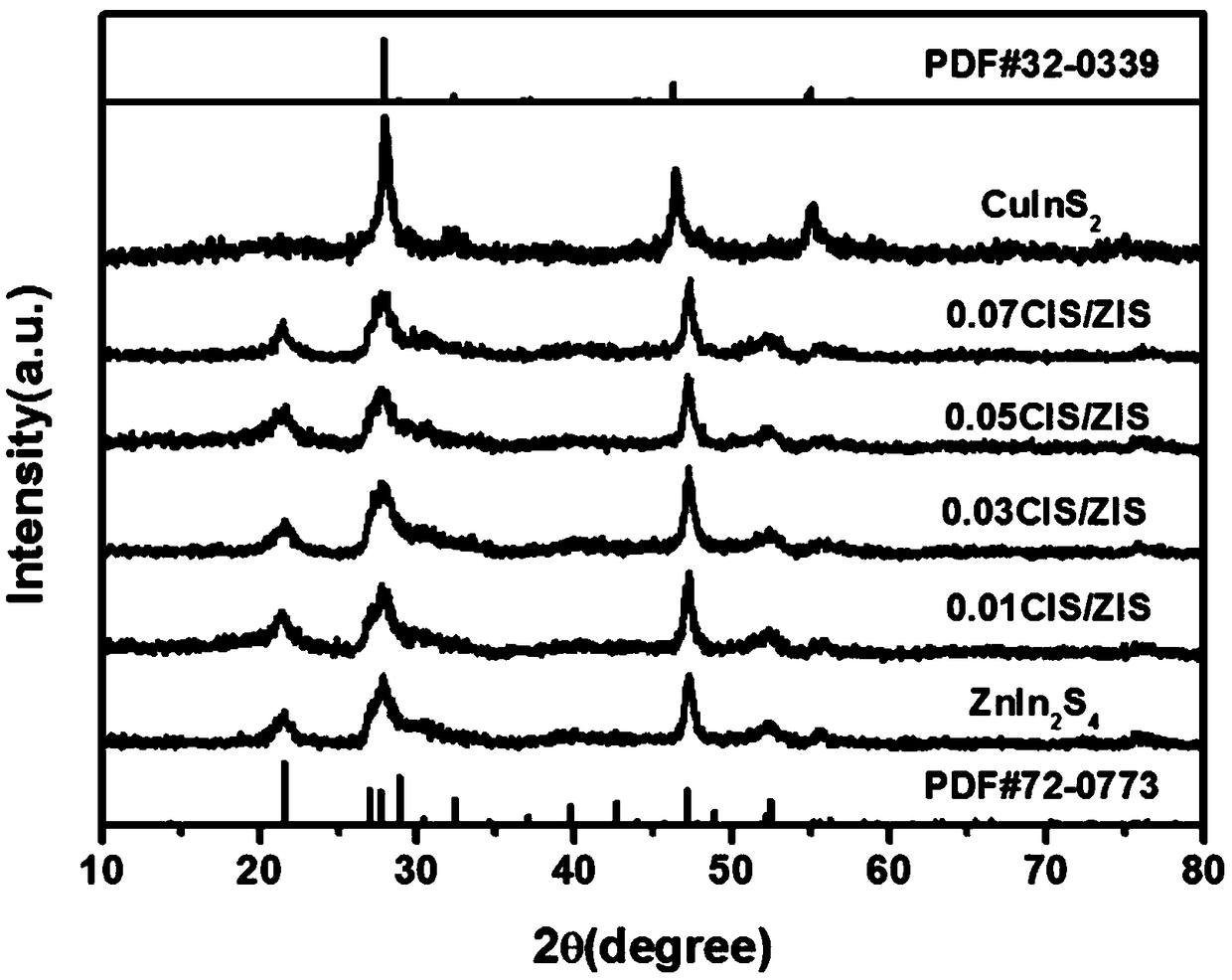

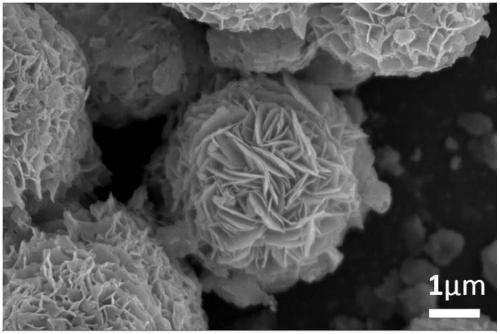

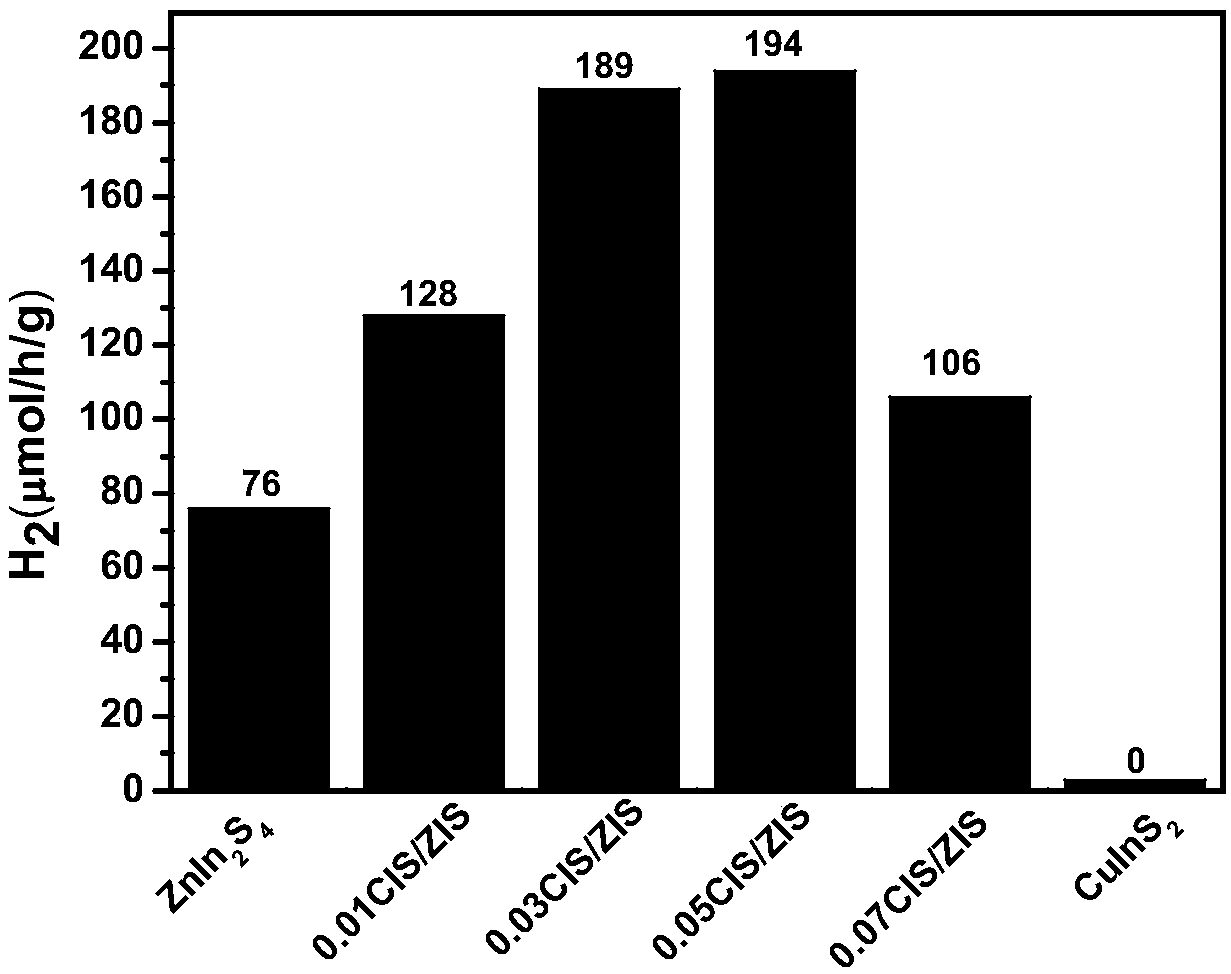

Preparation method and application of non-noble metal copper indium sulphide/zinc indium sulphide compound photocatalyst

ActiveCN109248694AEasy transferInhibitory recombination ratePhysical/chemical process catalystsHydrogen productionSynthesis methodsLight driven

The invention belongs to the field of photocatalytic materials, and provides a non-noble metal copper indium sulphide / zinc indium sulphide compound photocatalyst with a wide visible-light response range, high photocatalytic activity and stability and a preparation method and application in visible-light response photocatalysis hydrogen production thereof. Firstly, a mixed aqueous solution of zincchloride, indium chloride and thioacetamide is subjected to high-temperature hydrothermal reaction to prepare zinc indium sulphide powder; then the zinc indium sulphide powder is dispersed in water through ultrasound, a mixture, indium chloride, cuprous chloride and thioacetamide are mixed, and through high-temperature hydrothermal reaction, the copper indium sulphide / zinc indium sulphide compoundphotocatalyst is prepared. The photocatalyst does not contain noble metal, the cost is lower, and the synthesis method is simple, so that the photocatalyst has wide application prospects in the fieldof visible-light drive photocatalysis.

Owner:QINGDAO UNIV

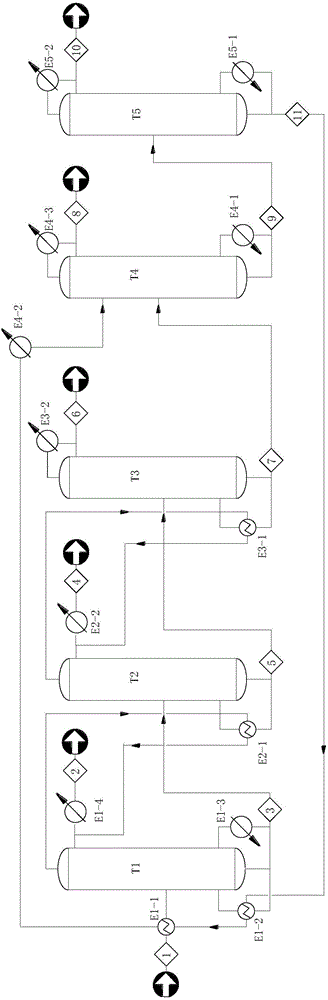

Device and method for deeply removing organic sulphides in methyl tertiary butyl ether (MTBE)

ActiveCN104829436AMTBE recovery increasedReduce process energy consumptionEther separation/purificationChemical industryReboilerMulti effect

The invention provides a device and a method for deeply removing organic sulphides in methyl tertiary butyl ether (MTBE). The device comprises a high-pressure multi-effect rectifying tower, a medium-pressure multi-effect rectifying tower, a normal-pressure multi-effect rectifying tower, an extraction rectifying tower and an extraction agent recycling tower connected in series; a condenser is arranged on the top of each tower; a reboiler is arranged at the bottom of each tower; a material outlet at the bottom of each tower is connected to a material inlet in the middle of a next tower through a pipeline; 90%-95% of qualified MTBE products can be distilled out through the tops of the multi-effect rectifying towers; the organic sulphides are enriched at the bottom of the extraction rectifying tower under the action of an extraction agent; remained MTBE distilled by the tops of the towers returns into a raw material tank; and the cycle repeats. By means of reasonable heat exchange network design, vapor from the tops of the towers and heat of the extraction agent are sufficiently utilized, so that energy consumption in a desulfurizing process is reduced; the total sulphur content of MTBE produced through a multi-effect rectifying and extraction rectifying coupling method is less than 10 ppm; deep sulphur removing requirements are satisfied; the total recovery rate of MTBE is up to 99.8%; and furthermore, the theoretical energy-saving efficiency is up to 53%.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

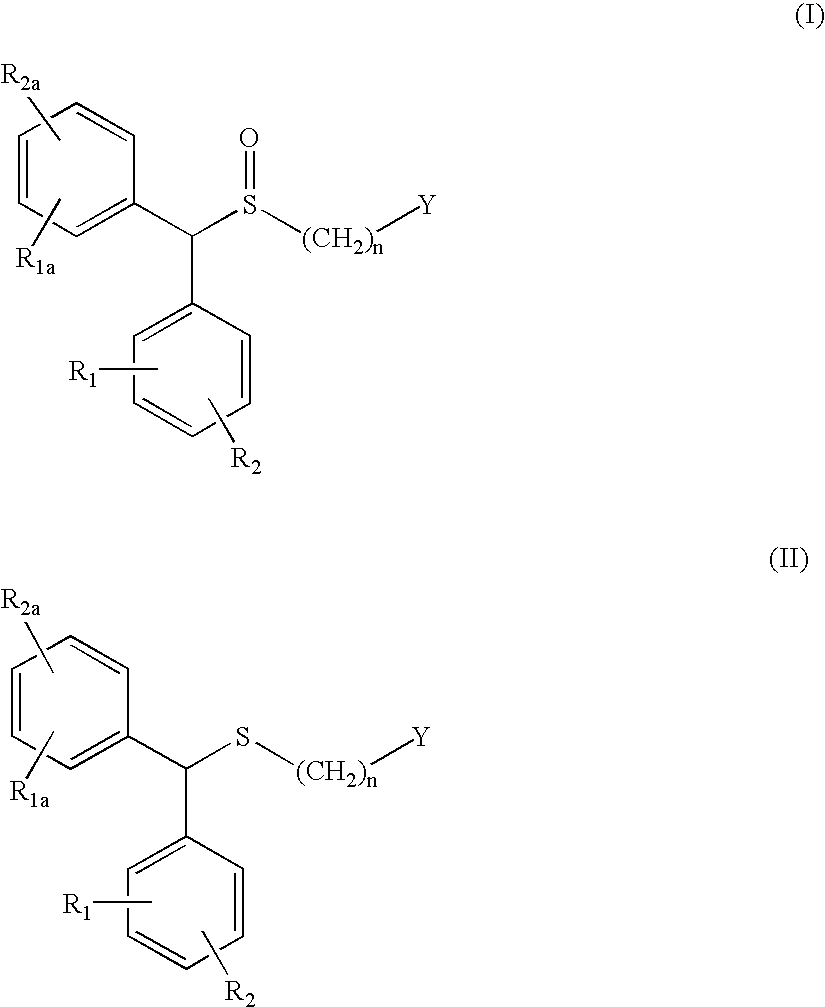

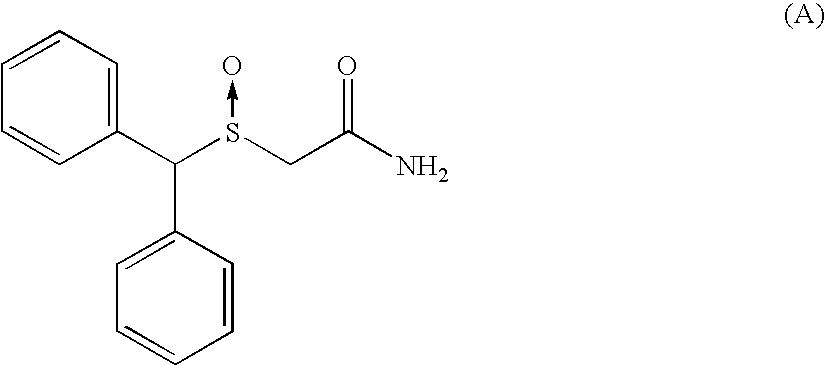

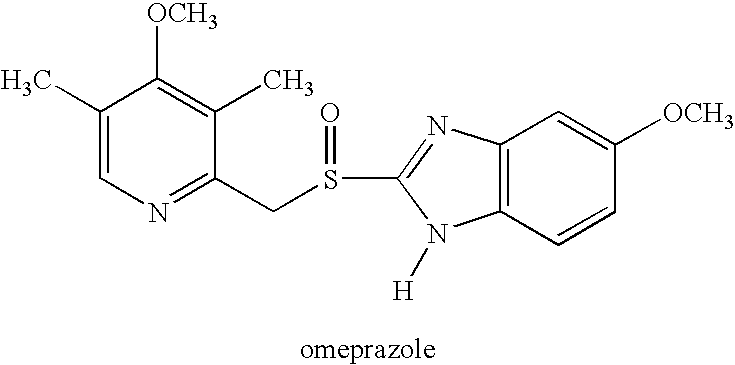

Process for enantioselective synthesis of single enantiomers of modafinil by asymmetric oxidation

InactiveUS7368591B2High enantioselectivityHigh yieldBiocideOrganic compound preparationOrganic solventEnantiomer

The invention relates to a method for preparing a sulphoxide compound of formula (I) either as a single enantiomer or in an enantiomerically enriched form, comprising the steps of:a) contacting a pro-chiral sulphide of formula (II) with a metal chiral complex, a base and an oxidizing agent in an organic solvent; and optionallyb) isolating the obtained sulphoxide of formula (I).wherein n, Y, R1, R1a, R2 and R2a are as defined in claim 1.

Owner:TEVA SANTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com