Device and method for deeply removing organic sulphides in methyl tertiary butyl ether (MTBE)

A technology of methyl tertiary butyl ether and sulfide, applied in organic chemistry, ether separation/purification, ether preparation, etc., can solve the problems of low operating cost, low energy consumption for desulfurization, low MTBE yield, etc., and achieve MTBE recovery Increased efficiency and reduced process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

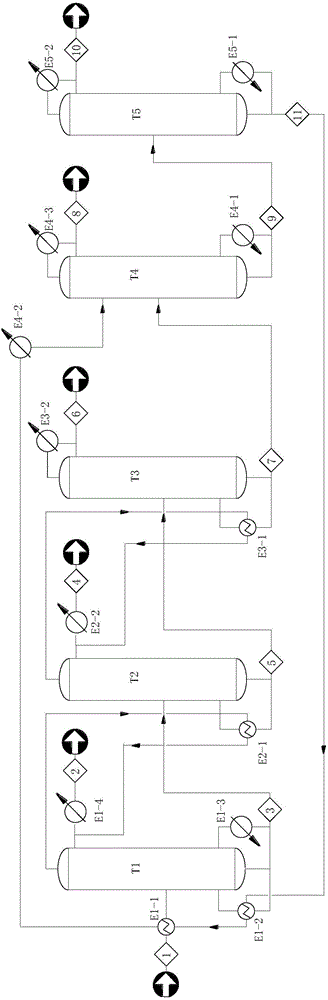

[0036] In this example, MTBE produced by a catalytic reaction distillation unit in a refinery is characterized by MTBE 99.05%, methanol 0.0123%, tert-butanol 0.0324%, methyl sec-butyl ether 0.51%, water 0.00438%, trimethyl -2-pentene 0.285%, diisobutene 0.0285%, 2-methyl-1-butene 0.0372%, isopentane 0.0399%, dimethyl disulfide 0.0247%, ethyl methyl disulfide 0.0149%, Methyl tert-butyl sulfide 0.0051%, diethyl disulfide 0.00175%, dimethyl sulfide 0.00325%. Simultaneously, in the present embodiment, T1 tower, T2 tower and T3 tower all adopt identical theoretical plate number, and extraction agent is C 12 Branched alkanes, all tower packings are wire mesh corrugated structured packing.

[0037] The separation requirements are realized through the following specific devices: the middle part of the high-pressure multi-effect rectification tower T1 is equipped with an MTBE raw material inlet, the raw material preheater E1-1 hot stream inlet port is connected to the T1 tower bottom ...

Embodiment 2

[0040] A method for deep removal of organic sulfides in MTBE, the overall process is the same as in Example 1, but the difference is that the extractant is selected from N-methylpyrrolidone, the total sulfur content is 4188ppm, and the sulfur-containing species is dimethyl Disulfide 0.1878%, ethyl methyl disulfide 0.1249%, methyl tert-butyl sulfide 0.0851%, diethyl disulfide 0.01125%, dimethyl sulfide 0.00975%. MTBE with a purity of 98.95% is used as raw material to enter the combined process. During the rectification and desulfurization process, the operating pressures of the T1 tower and T2 tower are controlled at 2.2 bar and 1.2 bar respectively, and the T3 tower is operated at normal pressure, and the total reflux is carried out to the rectification tower. The operating pressure and temperature After stabilization, adjust the reflux ratios of T1, T2 and T3 to 3, 3 and 6 respectively. After the rectification tower is stabilized, the temperature at the bottom of T1 is control...

Embodiment 3

[0042] A method for deep removal of organic sulfides in MTBE, the overall process is the same as in Example 1, but the difference is that the extractant is a mixture of N-methylpyrrolidone and tributyl phosphate, N-methylpyrrolidone and phosphoric acid The tributyl ester is 1.5, the mass mixing ratio of N-methylpyrrolidone and tributyl phosphate is 2, the total sulfur content is 68ppm, the sulfur-containing species are dimethyl disulfide 0.0159%, ethyl methyl disulfide 0.0071% %, methyl tert-butyl sulfide 0.0028%, MTBE with a purity of 99.10% is used as raw material to enter the combined process, during the rectification and desulfurization process, the operating pressures of the T1 tower and the T2 tower are controlled at 2 bar and 1 bar respectively, and the T3 tower is operated at normal pressure. After the total reflux to the operation pressure and temperature of the rectification tower is stable, adjust the reflux ratio of T1 tower, T2 tower and T3 tower to 2, 2 and 4 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com