Method to obtain a corrosion-resistant and shiny substrate

An anti-corrosion, substrate technology, especially in the field of very bright metal or non-metal substrates, which can solve the problems of yellowing, loss of adhesion of the silver layer to the substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

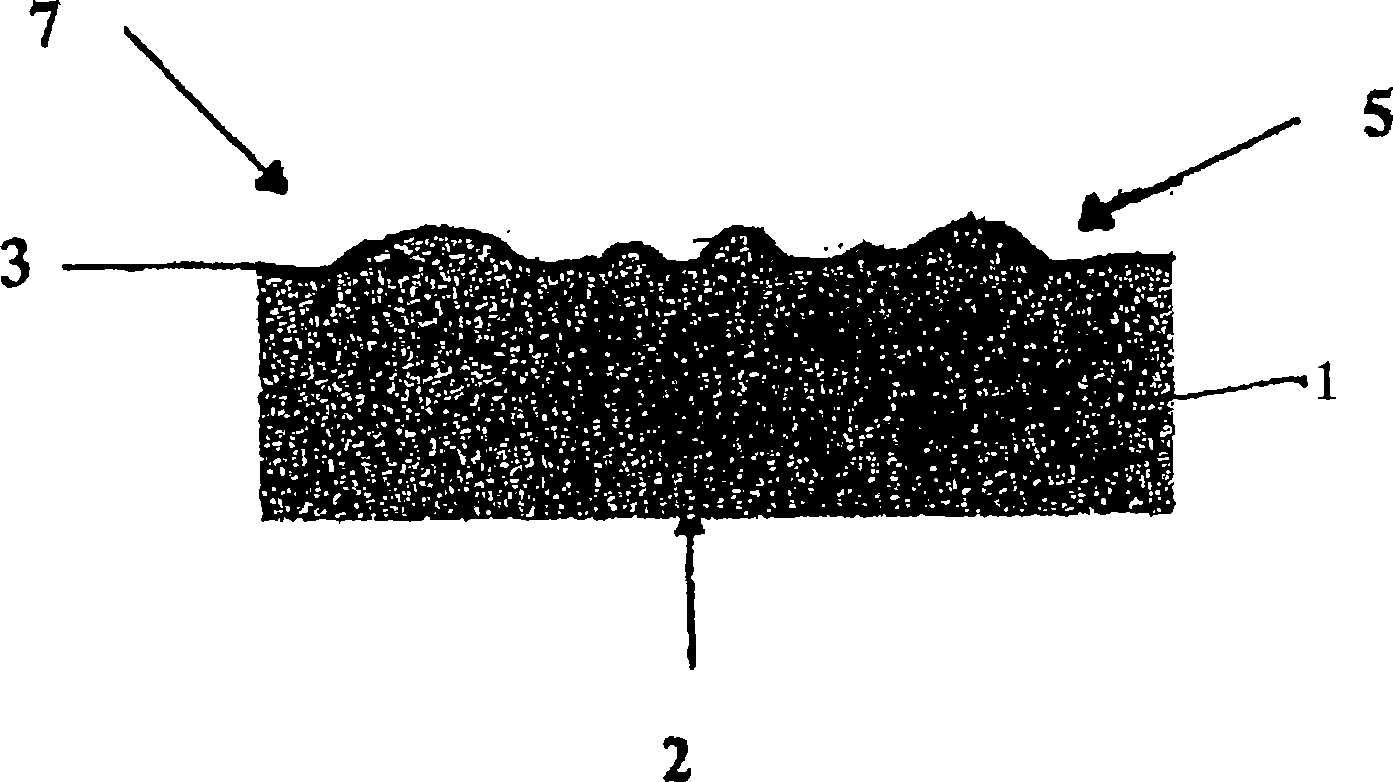

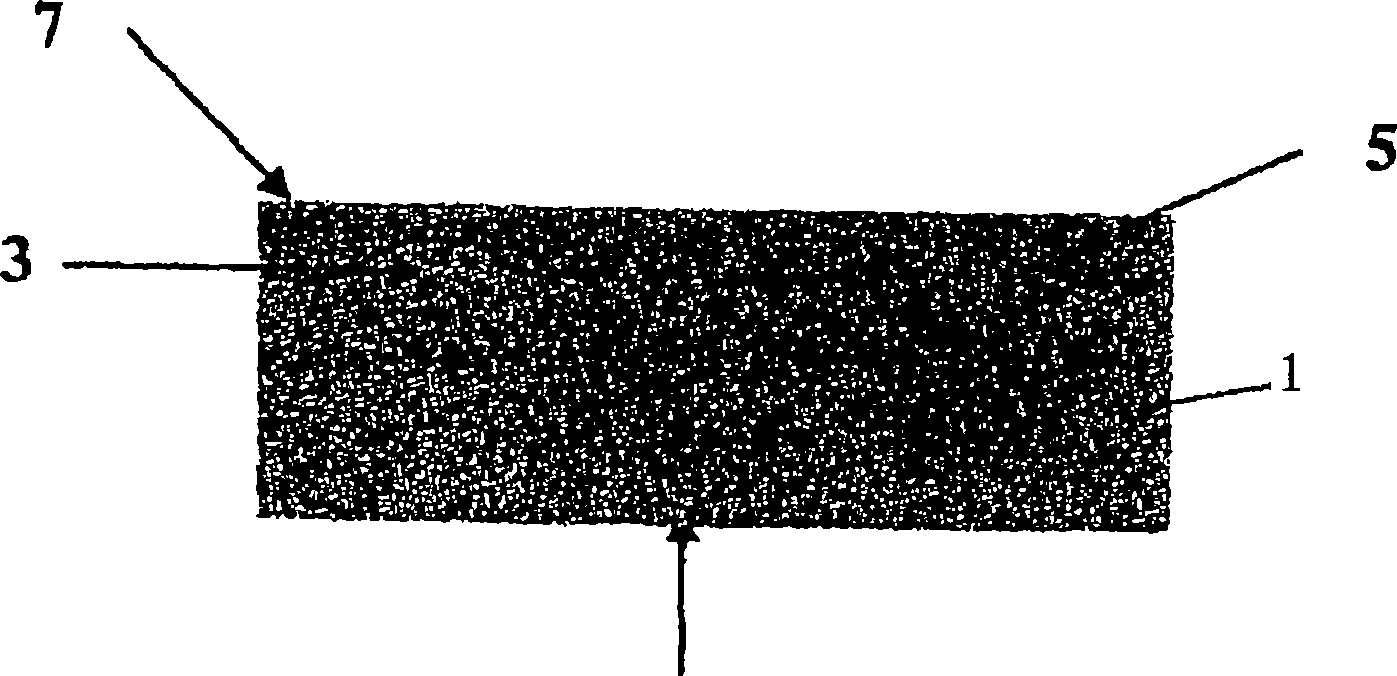

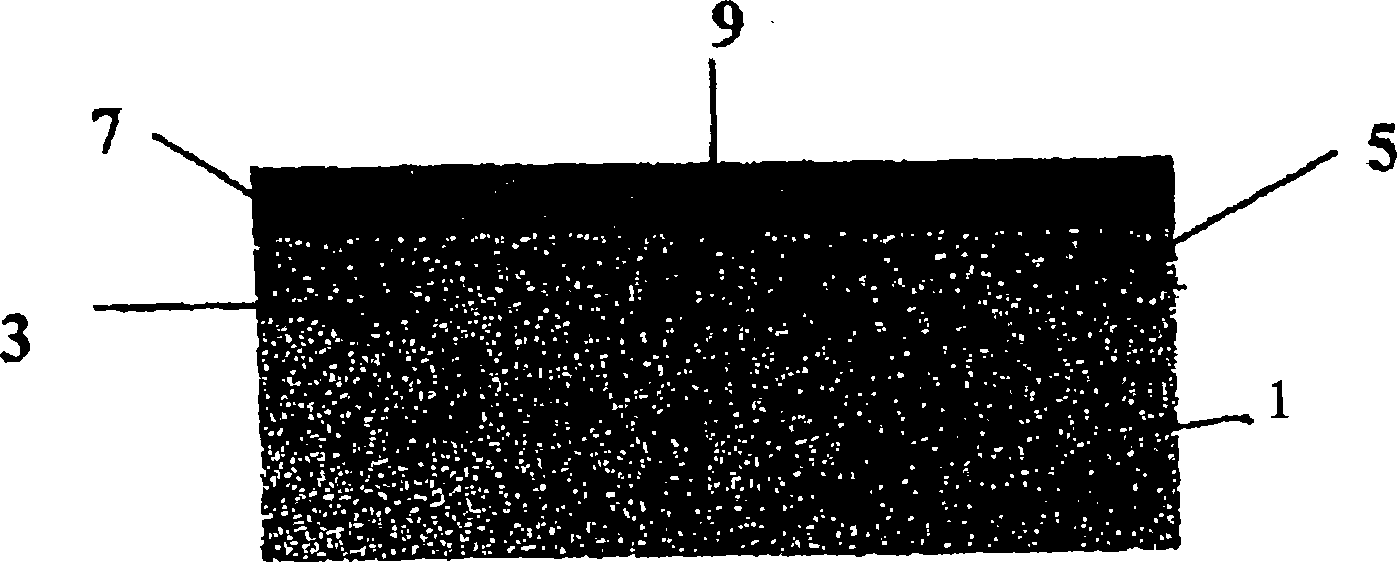

[0109] The sequence of embodiments of the method according to the invention will now be described with reference to the coating of light metal rims. Figure 1a A schematic partial cross-sectional view of the first substrate 1 is shown in cross-section of an aluminum light metal rim 2 . For the sake of clarity, the unevenness 3 of the metal surface is drawn and shown schematically. Firstly, the surface of the substrate 1 can be degreased in two etching steps. This is to remove the release agent residue from the substrate manufacturing process that may exist on the surface of the substrate 1 . In particular, the two degreasing steps are carried out in such a way that the light metal rim 2 is first immersed in a preferably alkaline etching bath. In a second etching step, the light metal rim 2 is immersed in a preferably alkaline etching bath at 60°C. Etching residues on the light metal rim 2 are subsequently removed by washing. The surface of the light metal rim 2 or substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com