Preparation method and application of non-noble metal copper indium sulphide/zinc indium sulphide compound photocatalyst

A non-precious metal, sulfur indium zinc technology, applied in the direction of physical/chemical process catalysts, non-metallic elements, chemical instruments and methods, etc., can solve the problem that noble metals are not suitable for large-scale production, unfavorable photogenerated charge transfer and separation, and reduce photocatalytic quantum Efficiency and other issues, to achieve the effect of improving photocatalytic performance, inhibiting recombination rate, and wide visible light response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

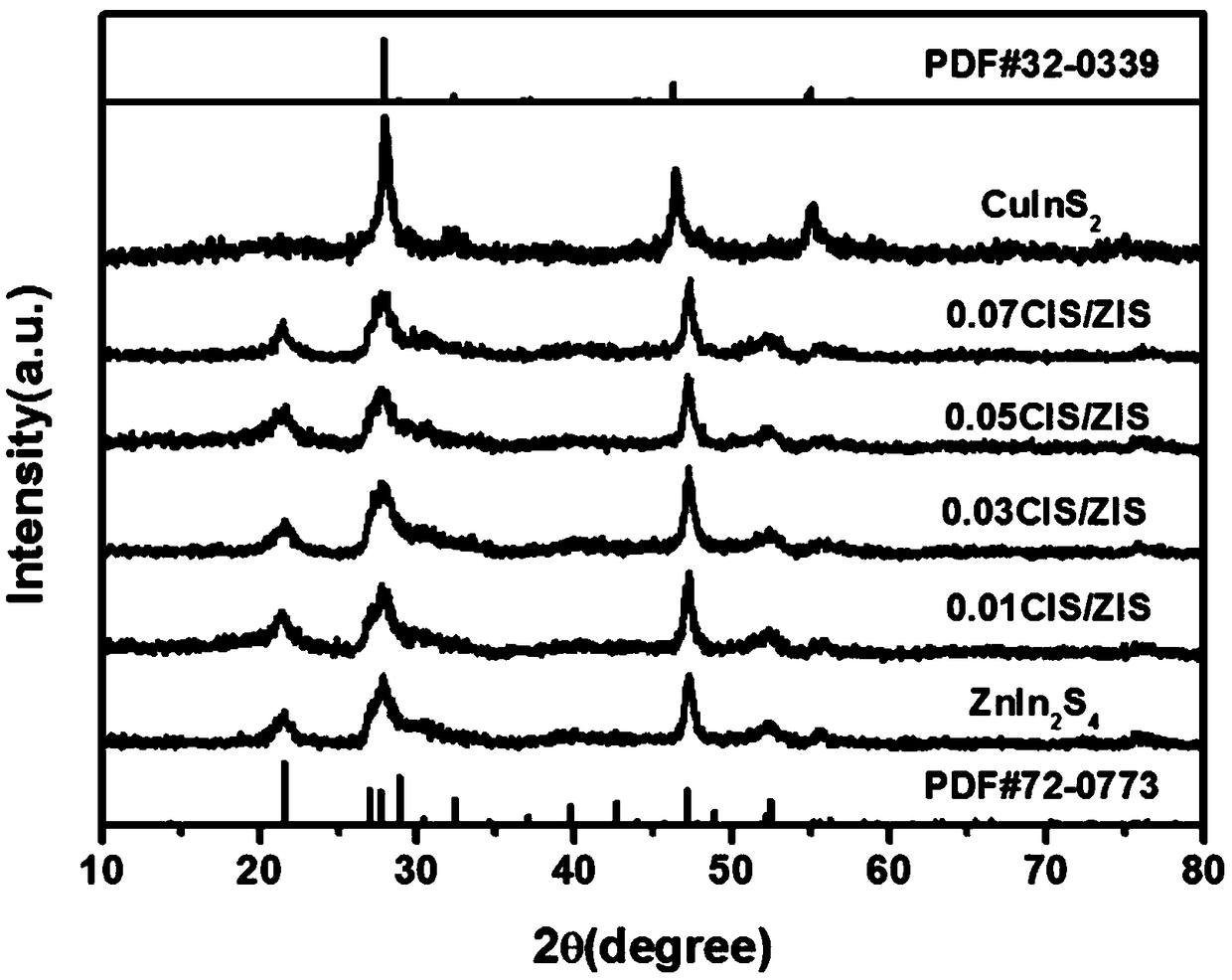

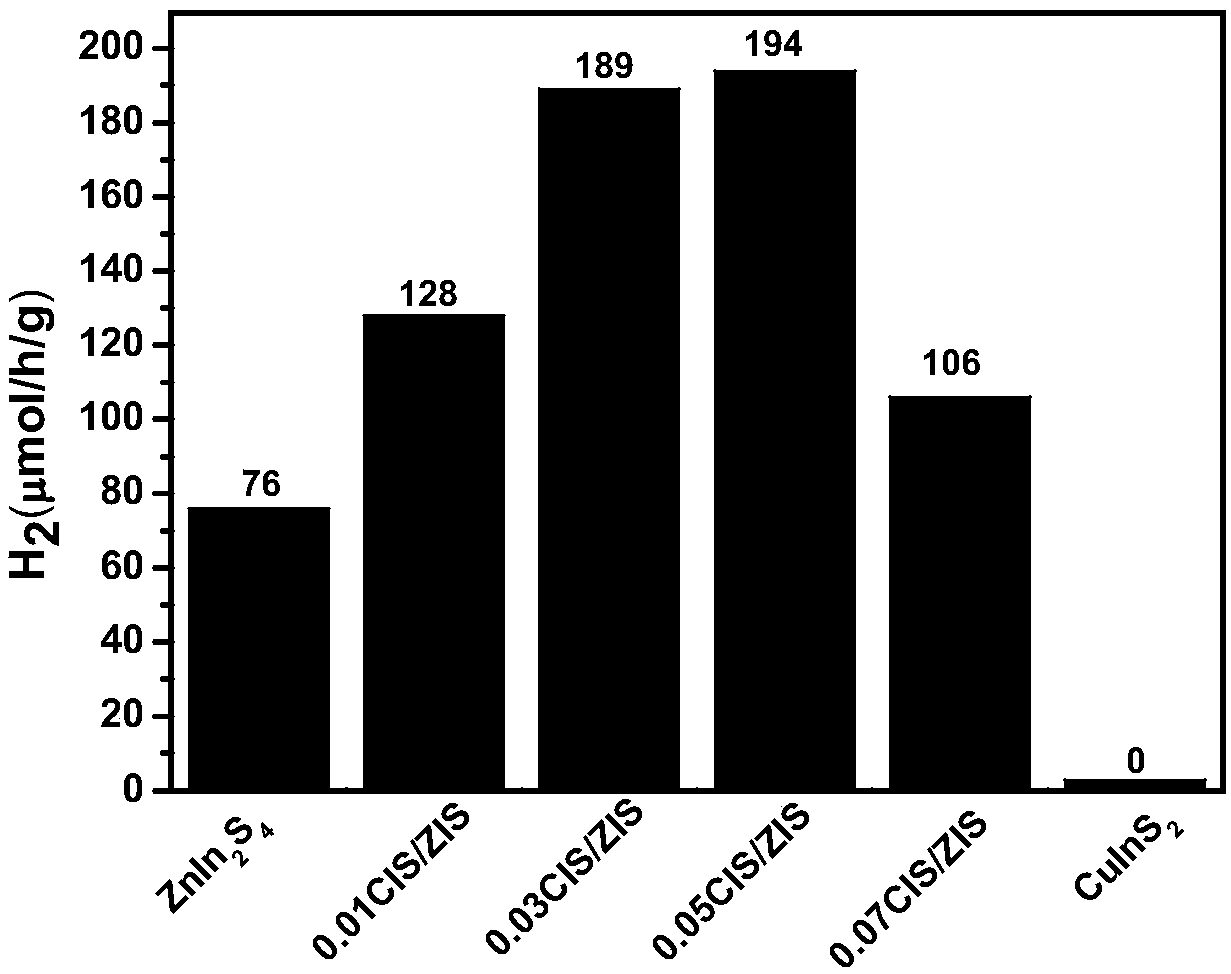

[0022] A preparation method of non-noble metal sulfur indium copper / sulfur indium zinc composite photocatalyst with wide visible light response.

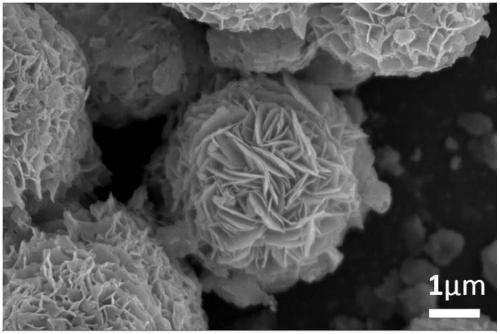

[0023] 2mmol zinc chloride, 4mmol indium chloride, and 16mmol thioacetamide were stirred in 40mL deionized water for 30 minutes to dissolve, and the aqueous solution was transferred to a 100mL stainless steel reactor lined with polytetrafluoroethylene, and reacted in an oven at 180°C for 18 hours. After cooling to room temperature, centrifuge and wash with deionized water 3 times with absolute ethanol and 1 time respectively, collect the precipitate and dry it in an oven at 80°C to obtain light yellow sulfur indium zinc powder.

[0024] Ultrasonicate 0.99mmol sulfur indium zinc powder in 40mL deionized water (frequency 45kHz) for 20 minutes, add 0.01mmol indium chloride, 0.01mmol cuprous chloride, 0.04mmol thioacetamide and stir evenly, transfer the suspension to 100mL A stainless steel reaction kettle lined with polytetrafluoroethy...

Embodiment 2

[0026] 2mmol zinc chloride, 4mmol indium chloride, and 16mmol thioacetamide were stirred in 40mL deionized water for 30 minutes to dissolve, and the aqueous solution was transferred to a 100mL stainless steel reactor lined with polytetrafluoroethylene, and reacted in an oven at 180°C for 18 hours. After cooling to room temperature, centrifuge and wash with deionized water 3 times with absolute ethanol and 1 time respectively, collect the precipitate and dry it in an oven at 80°C to obtain light yellow sulfur indium zinc powder.

[0027] Ultrasonicate 0.97mmol sulfur indium zinc powder in 40mL deionized water (frequency 45kHz) for 20 minutes, add 0.03mmol indium chloride, 0.03mmol cuprous chloride, 0.12mmol thioacetamide and stir evenly, transfer the suspension to 100mL A stainless steel reaction kettle lined with polytetrafluoroethylene was reacted in an oven at 180°C for 18 hours. After cooling to room temperature, it was washed with deionized water three times and anhydrous e...

Embodiment 3

[0029] 2mmol zinc chloride, 4mmol indium chloride, and 16mmol thioacetamide were stirred in 40mL deionized water for 30 minutes to dissolve, and the aqueous solution was transferred to a 100mL stainless steel reactor lined with polytetrafluoroethylene, and reacted in an oven at 180°C for 18 hours. After cooling to room temperature, centrifuge and wash with deionized water 3 times with absolute ethanol and 1 time respectively, collect the precipitate and dry it in an oven at 80°C to obtain light yellow sulfur indium zinc powder.

[0030] Ultrasonicate 0.95mmol sulfur indium zinc powder in 40mL deionized water (frequency 45kHz) for 20 minutes, add 0.05mmol indium chloride, 0.05mmol cuprous chloride, 0.20mmol thioacetamide and stir evenly, transfer the suspension to 100mL A stainless steel reaction kettle lined with polytetrafluoroethylene was reacted in an oven at 180°C for 18 hours. After cooling to room temperature, it was washed with deionized water three times and anhydrous e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com