Vacuum heat collector

A heat collector and heat collecting tube technology, applied in the field of solar energy, can solve the problems of complex structure of heat collecting tube, high manufacturing and installation costs, complicated manufacturing process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

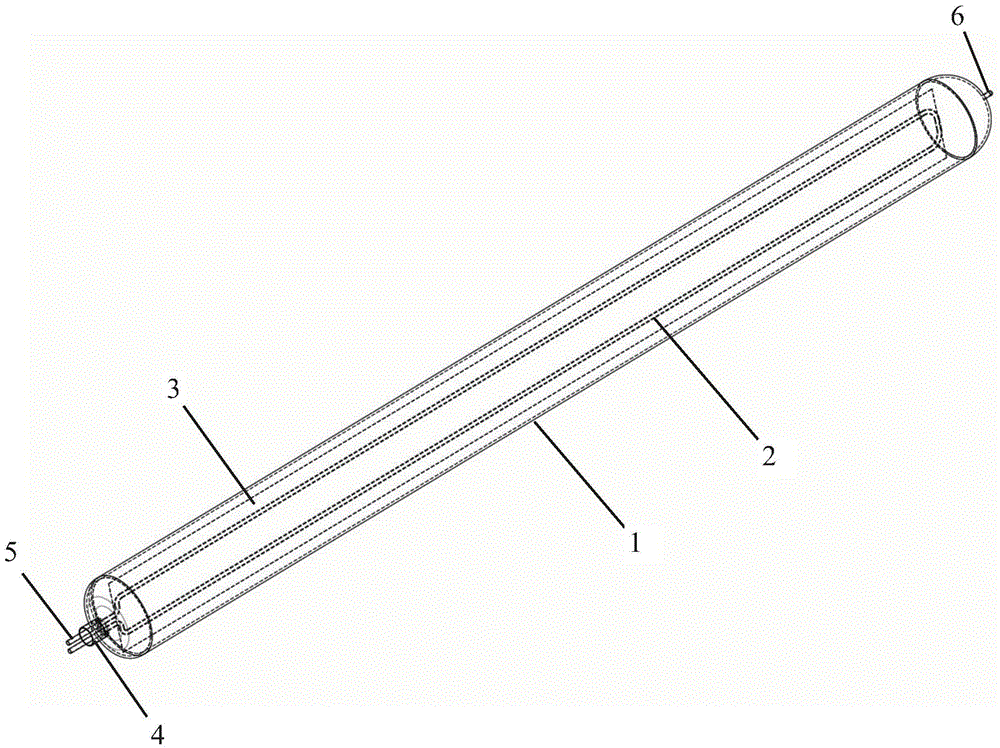

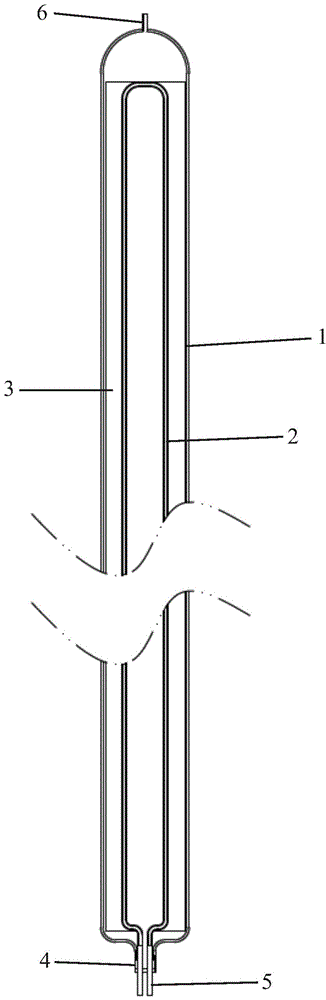

[0029] Such as figure 1 and 2 As shown, the heat collector of the present invention includes a housing 1, a U-shaped heat collecting tube 2, a heat absorbing plate 3 and a front end cover 4, wherein the housing includes a light-facing surface and a backlight surface, and the housing is provided with a vacuum nozzle 6 ; The U-shaped heat collecting tube 2 is fixedly installed in the housing, and the inlet and outlet ends of the U-shaped heat collecting tube 2 are connected with the sealing sleeve 5, and the sealing sleeve passes through the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com