Pipeline heat preservation structure

A technology of pipeline insulation and pipeline outer wall, which is applied in pipeline protection, thermal insulation, and pipeline protection through thermal insulation, etc., can solve problems such as unfavorable environmental protection and long degradation time of fiber materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the present invention, the preparation method of the heat insulation board includes the following steps:

[0047] (1) Mix silicon dioxide, aluminum oxide, silicon carbide, fiber and silica fume evenly, leave to exhaust to obtain a mixed powder; then introduce the mixed powder into a mold, dry press and form it, and obtain an insulating core material;

[0048] (2) Spray the silicon solution on the surface of the insulation core material, and dry to obtain the insulation core layer;

[0049] (3) Packing the thermal insulation core layer with packaging materials, and the product is obtained.

[0050] In a preferred embodiment, the source of the silica sol is not particularly limited, and all commercially available silica sols are suitable for the present invention.

[0051] In a preferred embodiment, the packaging material is not particularly limited, and organic polymer films, glass fiber cloth, aluminum foil fiber cloth and the like can be mentioned.

[0052] In a mor...

Embodiment 1

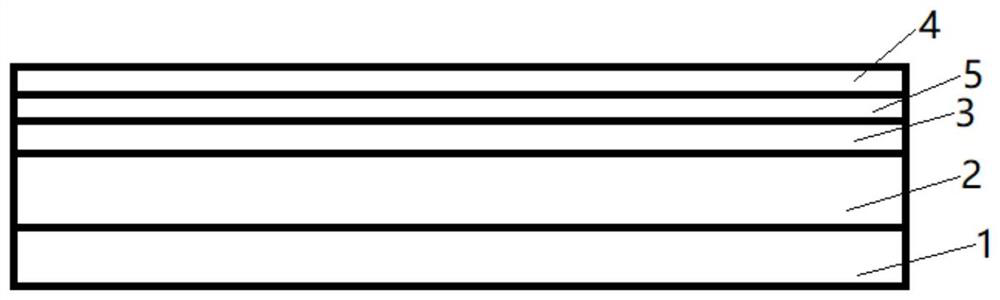

[0073] Embodiment 1 provides a kind of pipe insulation structure, such as figure 1 As shown, the pipeline insulation structure is sequentially provided with a heat insulation layer 2, a fixed layer 3, a reflection layer 5 and a protective layer 4 from the pipeline outer wall 1; the heat insulation layer 2 includes two layers of heat insulation boards with a thickness of 20mm; The two-layer insulation board adopts the method of staggered stitching; the fixed layer 3 is glass ribbon; the reflection layer 5 is aluminum foil; the protective layer 4 is iron sheet; connection; the fixed layer 3 is wrapped on the heat insulating layer 2; the reflective layer 5 is wrapped on the fixed layer 3; the protective layer 4 is wrapped on the reflective layer 5.

[0074] The raw materials for the preparation of the thermal insulation board include the following components: 70 parts of silicon dioxide, 20 parts of aluminum oxide, 20 parts of silicon carbide, 15 parts of fiber, 20 parts of silic...

Embodiment 2

[0078] The difference between embodiment 2 and embodiment 1 is that no reflective layer is included.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com