Guide plate and fuel cell stack containing the same

A fuel cell and deflector technology, which is applied in the direction of fuel cell grouping, fuel cell components, battery electrodes, etc., can solve problems such as reducing the service life of fuel cells, affecting the output power of fuel cells, and electrochemical corrosion of membrane electrodes. Achieve the effects of improving output efficiency, reducing voltage difference, and stabilizing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

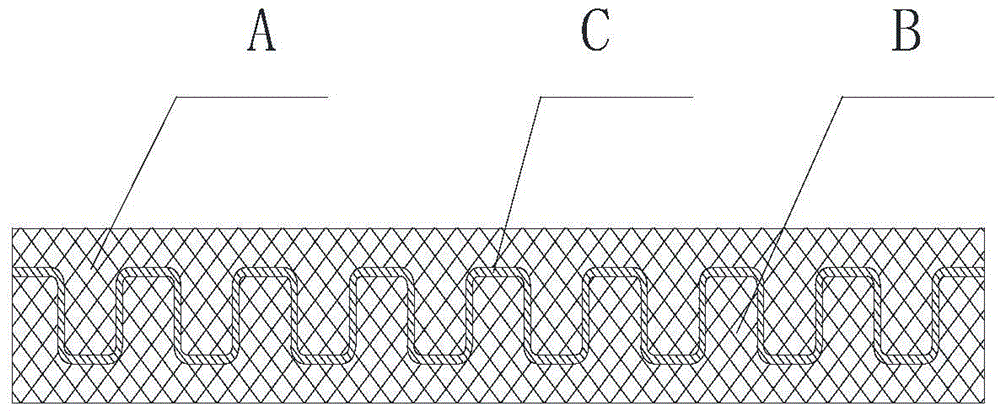

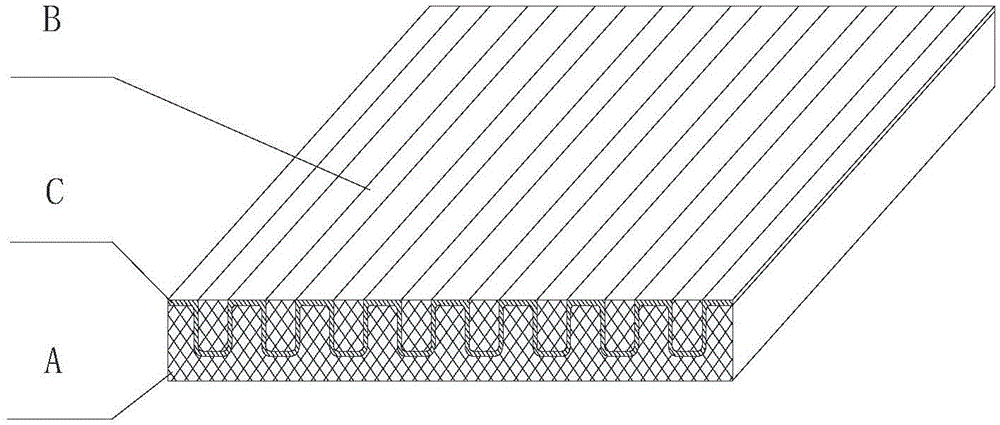

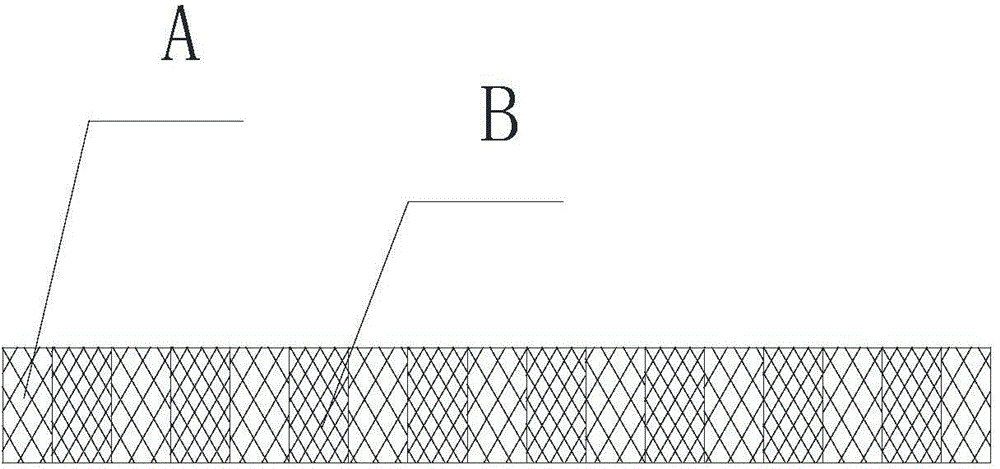

[0045] Such as Figure 4 As shown, a fuel cell deflector includes a cathode plate 1 and an anode plate 2, a separator 3 is arranged between the cathode plate 1 and the anode plate 2, the cathode plate 1 includes an outer frame, and an outer frame The deflector is sealed in the frame. The structure of the deflector adopts the first structure above: a plate made of two materials with different pore diameters sandwiches a membrane material 6, and the two materials with different pore diameters The plates are respectively recorded as: porous plate a4 and porous plate b5, the porous plate a4 is used as the oxidant flow field in this embodiment as the air flow field, and the porous plate b5 as the cooling fluid flow field is used as the water flow field in this embodiment; the described One side of the porous plate b5 is flat, and the other side is provided with a plurality of diversion grooves. The membrane material 6 is laid on the side with the diversion grooves. One side of the ...

Embodiment 2

[0049] see Figure 1~6 ,Such as Figure 7 Said, a fuel cell deflector, including a cathode plate 1 and an anode plate 2, a separator 3 is provided between the cathode plate 1 and the anode plate 2, and the cathode plate 1 includes an outer frame and an outer frame The deflector is installed in the inner seal. The structure of the deflector adopts the above-mentioned second structure: a plate made of two materials with different apertures is sandwiched by a membrane material 6, and a plate made of two materials with different apertures is: porous plate a4 and porous plate b5, porous plate a4 is used as the oxidant flow field, and porous plate b5 is used as the cooling fluid flow field; image 3 As shown, one side of the porous plate b5 is flat, the other side is provided with a plurality of diversion grooves, the membrane material 6 is laid on the side provided with the diversion grooves, and the porous plate a4 is composed of multiple It is composed of independent cuboid blo...

Embodiment 3

[0052] The cathode plate and the anode plate have the same structure, which is the third structure (such as image 3 As shown), the membrane material 6 is only set between the porous plate c7 and the porous plate d8 as the cathode plate, and the membrane material 6 is formed by stacking four membrane materials with pore diameters of 0.1 micron, 0.2 micron, 0.9 micron and 1.0 micron. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com