A kind of production method of coffee concentrate

A production method and concentrate technology, applied in the field of coffee concentrate production, can solve problems such as damage to active ingredients, unsatisfactory effects, unstable coffee concentrate, etc., to save energy and water resources, and solve serious aroma loss, The effect of improving the utilization rate of coffee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

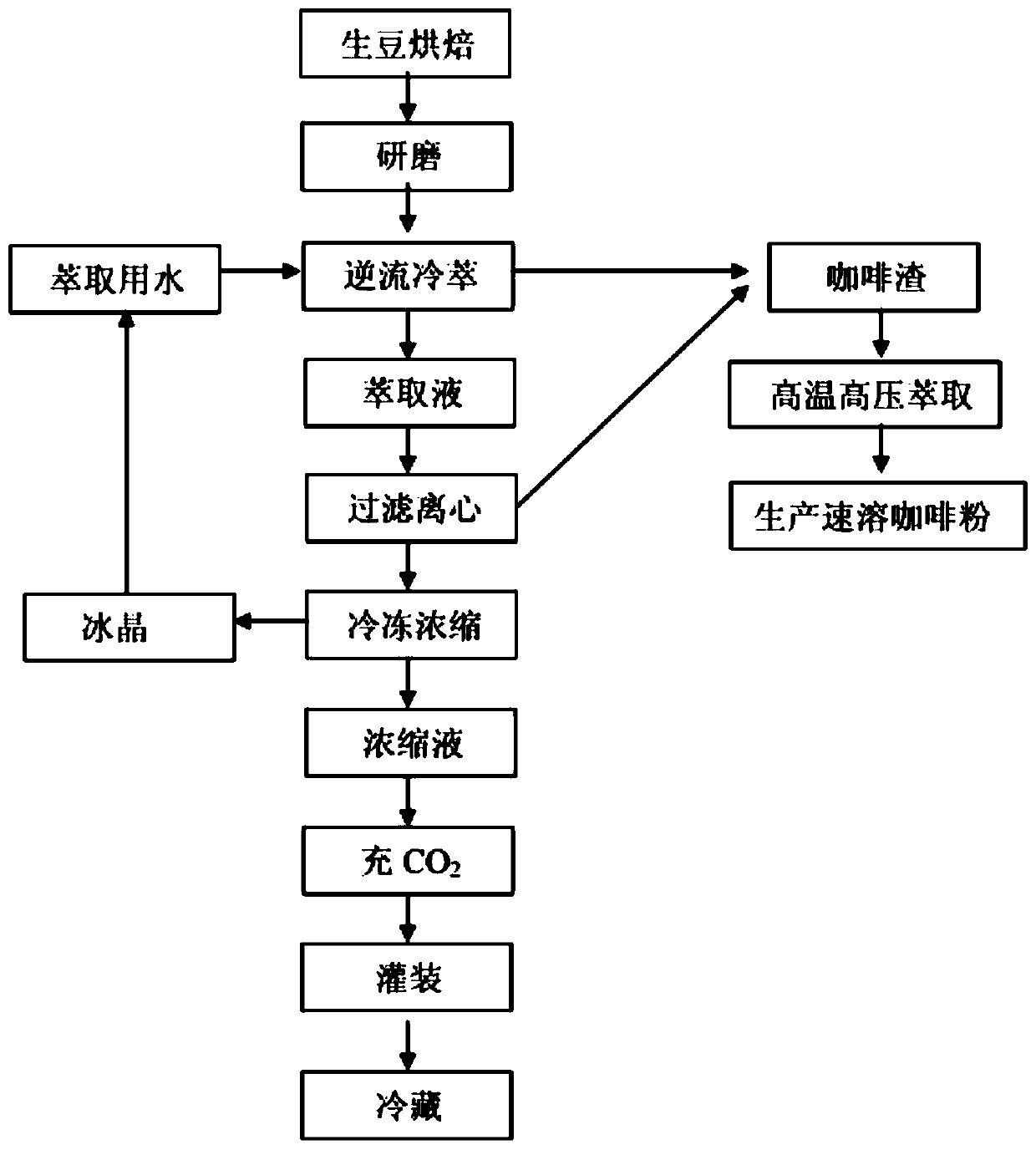

Image

Examples

Embodiment 1

[0052] A production method of high-quality coffee concentrate, comprising the following steps:

[0053] 1) Green bean roasting and grinding: Select Yunnan Arabica coffee green beans for roasting (moderate roasting, L value 85-95), and grind to a particle size of 8-40 mesh after roasting to obtain coffee particles;

[0054] 2) Countercurrent cold extraction: Put the coffee particles into the countercurrent equipment (using double-helix countercurrent extraction), add water for countercurrent cold extraction, the weight ratio of the coffee particles to water is 1:2, the extraction temperature is 25°C, and the extraction time is 45min. Collect the extract;

[0055] The coffee grounds obtained after countercurrent cold extraction are discharged from the countercurrent extraction equipment, and then enter the columnar extraction tank for high temperature and high pressure extraction to produce instant powder;

[0056] 3) Filtration and centrifugation: filter the above-mentioned co...

Embodiment 2

[0065] A production method of high-quality coffee concentrate, comprising the following steps:

[0066] 1) Roasting and grinding of green beans: choose green beans of Yegjashef coffee from Ethiopia for roasting (moderate roasting, L value 90-95), and grind to a particle size of 8-40 mesh after roasting to obtain coffee particles;

[0067] 2) Countercurrent cold extraction: Put the coffee particles into the countercurrent equipment (using double-helix countercurrent extraction), add water for countercurrent cold extraction, the weight ratio of the coffee particles to water is 1:4, the extraction temperature is 15°C, and the extraction time is 75min. Collect the extract;

[0068] The coffee grounds obtained after countercurrent cold extraction are discharged from the countercurrent extraction equipment, and then enter the columnar extraction tank for high temperature and high pressure extraction to produce instant powder;

[0069] 3 Filtration and centrifugation: filter the abo...

Embodiment 3

[0078] A production method of high-quality coffee concentrate, comprising the following steps:

[0079] 1) Green bean roasting and grinding: Mandheling coffee green beans are selected for roasting (deep roasting, L value 75-85), and after roasting, grind to a particle size of 8-40 mesh to obtain coffee particles;

[0080] 2) Countercurrent cold extraction: Put the coffee particles into the countercurrent equipment (using double-helix countercurrent extraction), add water for countercurrent cold extraction, the weight ratio of the coffee particles to water is 1:5, the extraction temperature is 4°C, and the extraction time is 90 minutes. Collect the extract;

[0081] The coffee grounds obtained after countercurrent cold extraction are discharged from the countercurrent extraction equipment, and then enter the columnar extraction tank for high temperature and high pressure extraction to produce instant powder;

[0082] 3 Filtration and centrifugation: filter the above collected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com