a spiral filter

A filter and screw technology, applied in the field of filtration equipment, can solve the problems of uneven use of filter material, long filtration time, waste of filter material, etc., and achieve the effect of improving filtration effect, prolonging filtration path, and preventing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

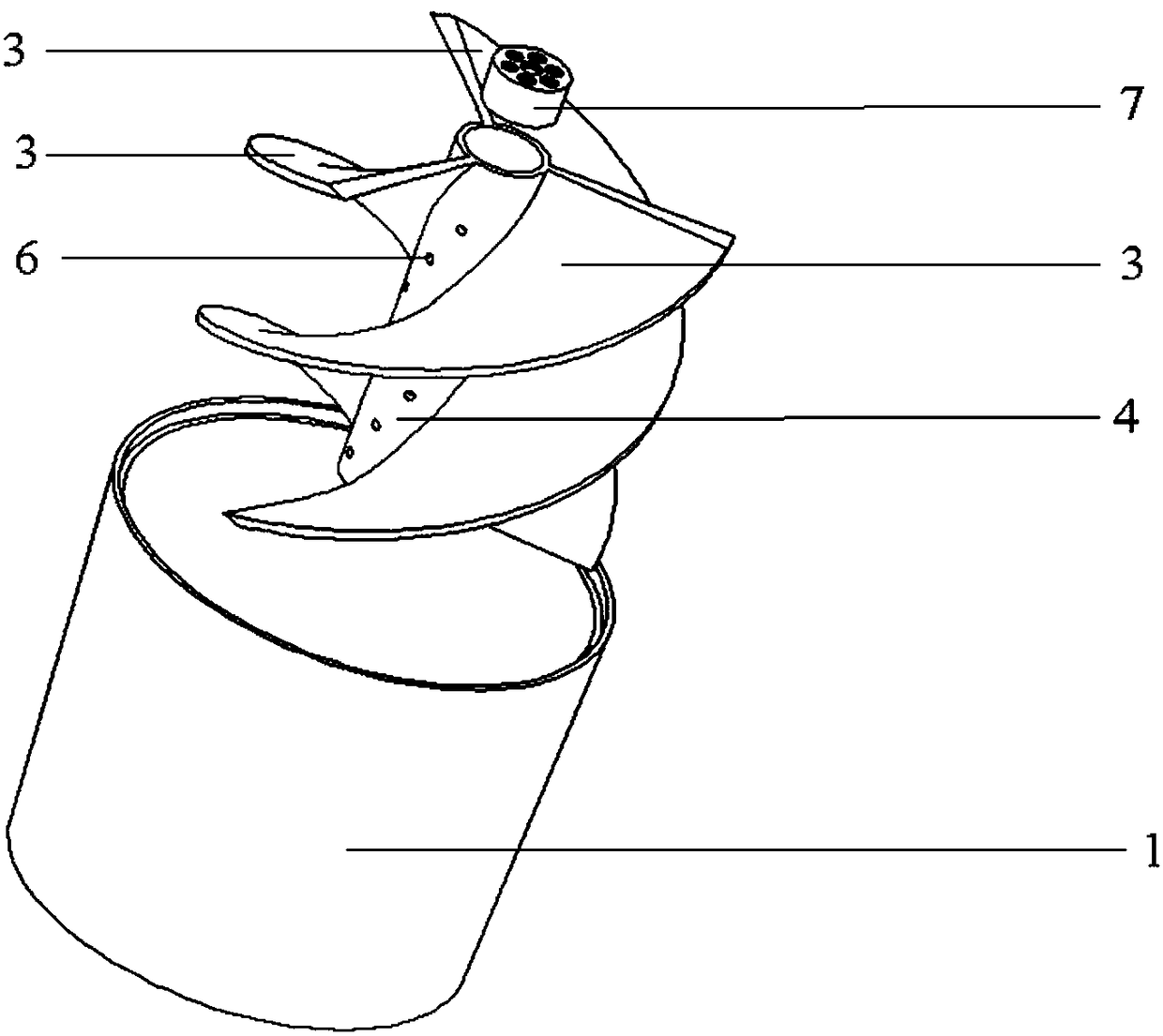

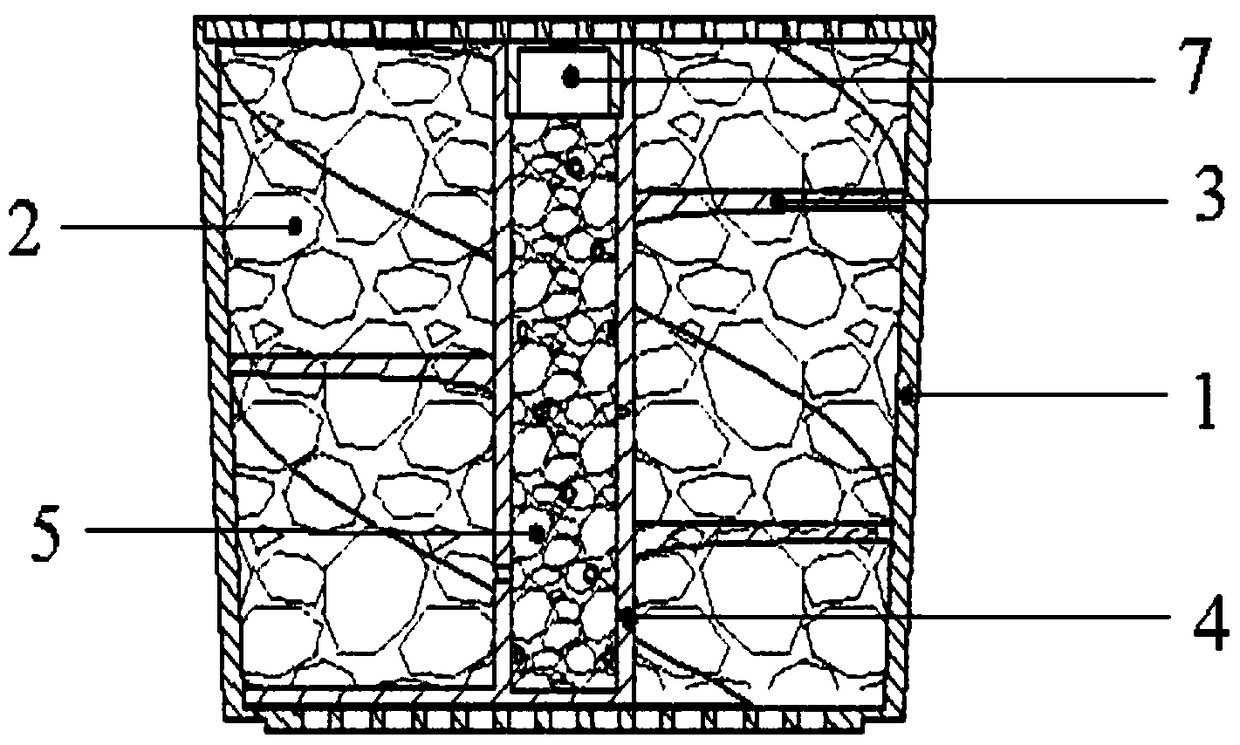

[0027] like Figure 1 to Figure 2 As shown, a spiral filter is composed of a filter element housing 1, a filter medium 2 and a spiral body assembly, and the filter medium 2 and the spiral body assembly are arranged in the filter element housing 1;

[0028] The helix assembly is composed of helix blades 3 and helix core 4; the helix core 4 is a hollow cylinder with a sealed bottom, and the helix core 4 is filled with anti-corrosion materials 5, and the side wall of the helix core 4 has 8 small holes 6, and the upper part of the helix core 4 is made of a helix Core cap 7 covers, and the diameter of spiral body core cap 7 is equal to the internal diameter of spiral body core 4, and spiral body core 4 is used for compressing anticorrosion material 5, and spiral body core cap 7 is the cylinder that has through hole in the middle. When the filtrate flows out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com