Mechanical ventilation countercurrent wet cooling tower group of rain area structure

A wet cooling and mechanical ventilation technology, applied in the field of cooling towers, can solve the problems of increasing the ventilation volume of the leeward tower and the low heat exchange efficiency of the leeward side of the cooling tower group, so as to solve the problems of low cooling efficiency, reducing flow stagnation, and reducing the scope of influence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

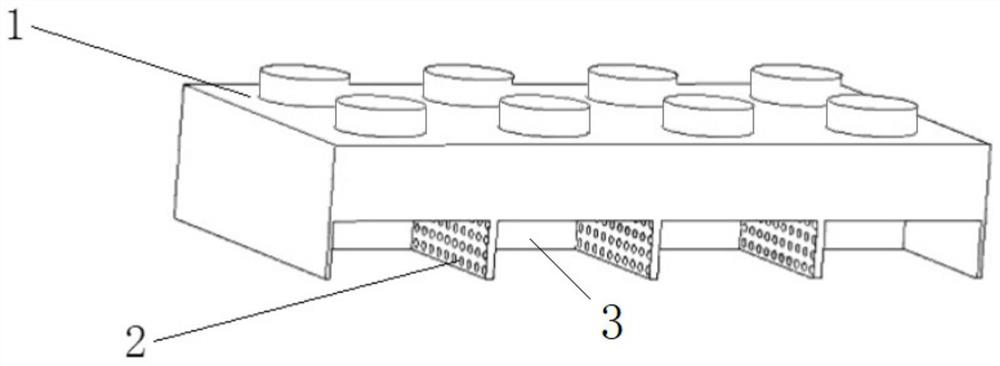

[0033] In a typical embodiment of the present invention, such as figure 1 As shown, a mechanical ventilation counterflow wet cooling tower group with rain area structure is proposed, including several rows of cooling tower groups, each row of cooling tower groups is provided with a plurality of cooling tower bodies 1, and the cooling tower groups form a mechanical ventilation counterflow wet cooling tower group (hereinafter referred to as the mechanical tower group).

[0034] The cooling tower body 1 is provided with a tower core element inside. The tower core element includes a spray area, a filler and a rain area. The spray area is located on the upper part of the rain area, and the filler is arranged between the spray area and the rain area.

[0035] The cooling tower bodies of the mechanical tower group are arranged adjacently, and the rain areas of adjacent cooling tower bodies are separated by tower walls, and the tower walls between the rain areas of adjacent cooling to...

Embodiment 2

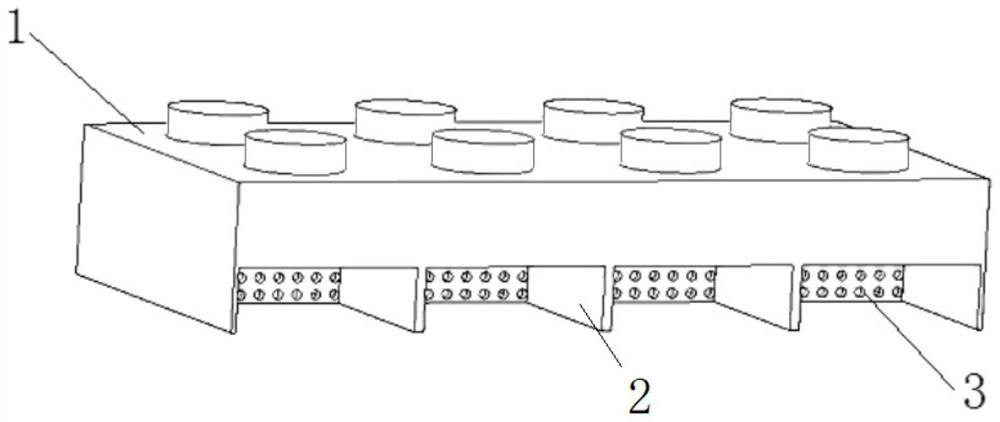

[0050] Such as figure 2 As shown, in the present embodiment, the second tower wall 3 spaced between the cooling tower groups is set as a porous structure, and the second tower wall 3 is arranged horizontally to connect the first tower wall 2 between the rain areas of the mechanical tower group. .

[0051] Specifically, this embodiment is a group of back-to-back mechanical towers. The mechanical towers in the mechanical tower group have single-sided air intake and are arranged in a back-to-back form. There are 4 mechanical towers in each row, arranged in 2 rows, and a total of 8 mechanical towers.

[0052] The transverse wall between the mechanical tower group rain areas is a porous structure, that is, the second tower wall 3 is a porous structure, and the porosity is set according to the operating conditions of the mechanical tower group, local prevailing wind speed, wind direction, and air temperature. The setting interval is Between 0.2 and 1.

[0053] The second tower wa...

Embodiment 3

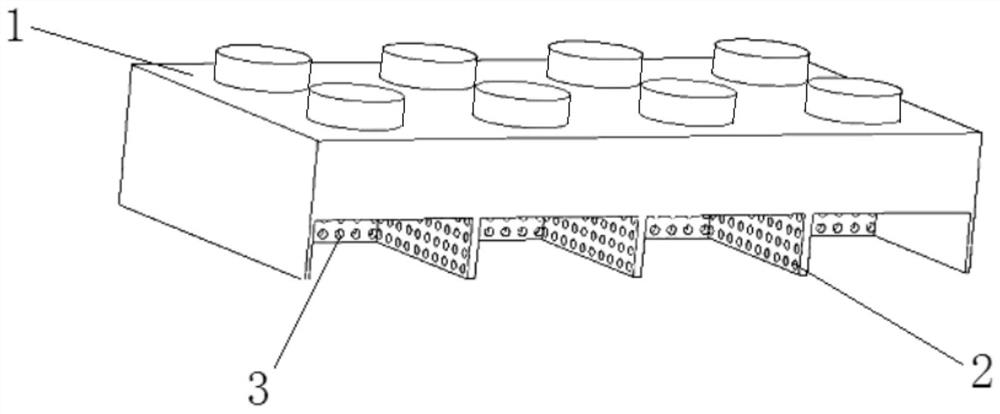

[0058] Such as image 3 As shown, what is set as the porous structure in the present embodiment is the first tower wall 2 and the second tower wall 3 between the rain areas of the mechanical tower group, wherein the first tower wall 2 is arranged vertically, and the second tower wall 3 is horizontally arranged. It is set to connect the first tower wall 2 between the rain areas of the mechanical tower group through the second tower wall 3 .

[0059] Specifically, this embodiment is a group of back-to-back mechanical towers. The mechanical towers in the mechanical tower group have single-sided air intake and are arranged in a back-to-back form. There are 4 mechanical towers in each row, arranged in 2 rows, and a total of 8 mechanical towers.

[0060] The horizontal wall and vertical wall between the mechanical tower group rain areas are all porous structures, that is, the first tower wall 2 and the second tower wall 3 are porous structures, and the porosity depends on the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com