Integrated reaction kettle for uniform pressure filtration, washing and drying of solid cationic etherifying agent

A cationic etherifying agent and reaction kettle technology, applied in the fields of organic chemistry, inert gas generation, chemical instruments and methods, etc., can solve the problems of large manual labor, poor filter-pressing effect, cumbersome process, etc., and achieve smooth pipeline and good effect. , the effect of excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

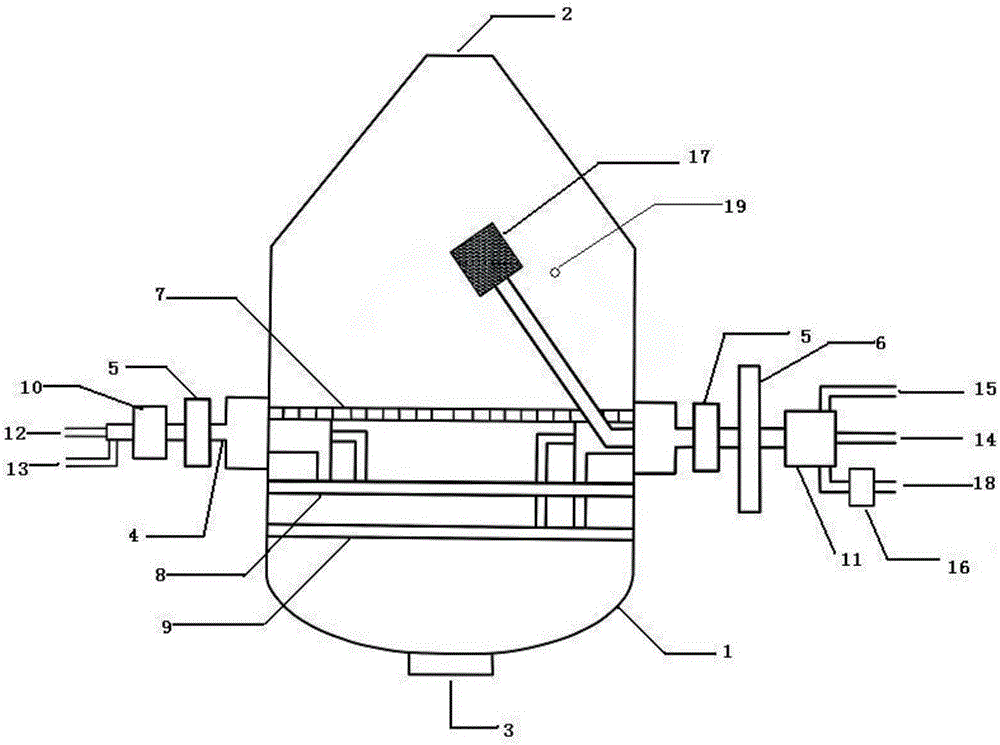

[0013] The specific implementation method is as follows, trimethylamine and epichlorohydrin with a molar ratio of 1:4 are combined in a synthesis reactor to generate a primary solid cationic etherifying agent after weighing;

[0014] Feeding: Before injecting the primary solid cationic etherification agent, adjust the rotating gear 6 to make the reaction kettle 1 vertical through the rotating bearing 5 and the rotating shaft 4, and check whether the equipment is normal. Turn on the vacuum pump 16, adjust the three-phase rotary joint 11, through the air inlet 17 and the air outlet 18, vacuumize for 15 minutes, the negative pressure is greater than 0.07MPa, open the feed inlet 19, inject the primary solid cationic etherification agent and place it on the filter screen 7 above;

[0015] Pressure filtration: connect the dry nitrogen pipe at the nitrogen inlet 14, adjust the three-phase rotary joint 11, blow nitrogen through the nitrogen inlet 14, and when the pressure in the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com